Menu

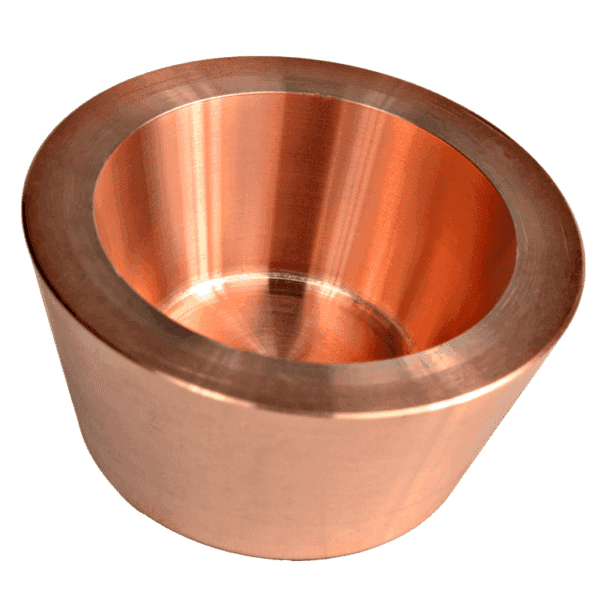

At MetalsTek Engineering, we have extensive experience in the production of crucibles and boats. We offer a wide range of sizes for our Copper E-Beam Crucibles and Standard Copper Crucibles, and we can also provide custom sizes upon request.

Material: Copper (Cu)

Purity: Cu 99.9% ~ 99.99%

Properties: 9.0g/cc Density, 1,084℃ M.P.

Type: Arc/Square/Rectangle/Cylinder/Boat

Capacity: 1mL ~2,000 mL

Surface: Polishing, Finish Turning

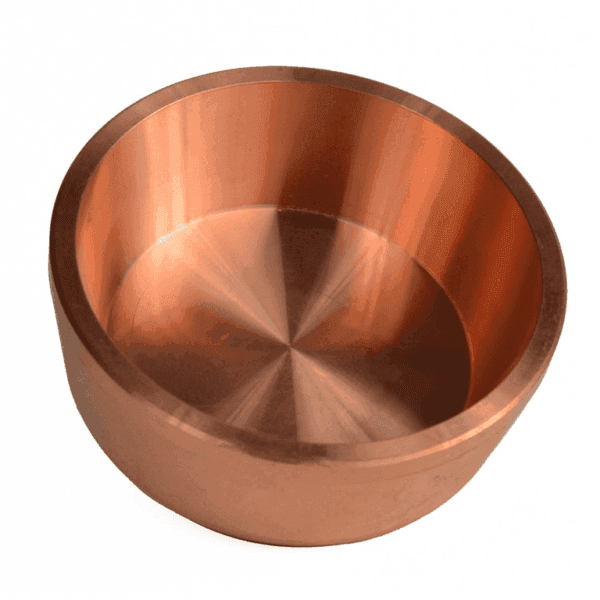

Material: Copper (Cu)

Purity: Cu 99.9% ~ 99.99%

Properties: 9.0g/cc Density, 1,084℃ M.P.

Type: Arc/Square/Rectangle/Cylinder/Boat

Capacity: 1mL ~2,000 mL

Surface: Polishing, Finish Turning

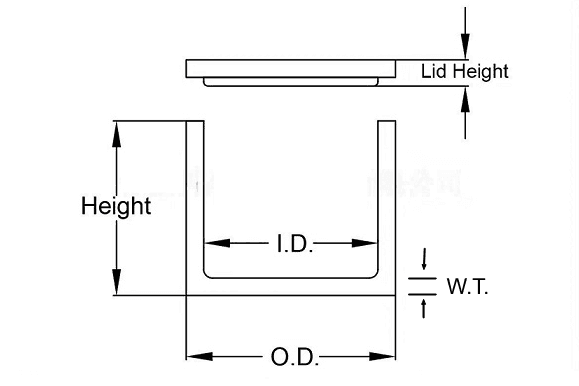

Material: Copper (Cu)

Purity: Cu 99.9% ~ 99.99%

Properties: 9.0g/cc Density, 1,084℃ M.P.

Shape: Per Drawing

Sizes: Tailored Size

| Outer Diameter (mm) | Wall Thickness (mm) | Height (mm) |

|---|---|---|

| 10 ~ 30 | 1.0 ~ 3 | 20 ~ 50 |

| 30 ~ 50 | 2~ 10 | 20 ~ 100 |

| 50 ~ 100 | 3 ~ 15 | 30 ~ 150 |

| 100 ~ 150 | 3 ~ 15 | 30 ~ 500 |

| 150 ~ 200 | 5 ~ 20 | 30 ~ 500 |

| 200 ~ 300 | 8 ~ 20 | 30 ~ 500 |

| 300 ~ 400 | 8 ~ 30 | 40 ~ 500 |

| 400 ~ 450 | 8 ~ 30 | 50 ~ 500 |

| 450 ~ 620 | 8~ 30 | 50 ~ 500 |

| Shape and size can be tailored. Rectangular Copper crucible is available. | ||

The Copper (Cu) Crucible is used as a container for samples during thermoanalytical measurements. The quality of the results obtained and important characteristics of the DSC signal can be influenced by the crucible. The copper crucible can also be used for oxidation induction time (OIT) determination and for the catalytic acceleration of oxidations. The copper material has a catalytic effect, and the flat construction of the crucible ensures perfect thermal contact.

Copper crucibles are used in various industrial and laboratory applications due to their excellent thermal conductivity and resistance to corrosion. Here are some common applications for copper crucibles:

These applications highlight the versatility and importance of copper crucibles in various high-temperature industrial and scientific processes.

Our Copper Foams are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.