Menu

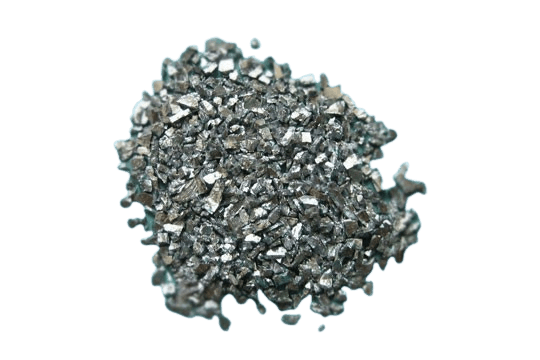

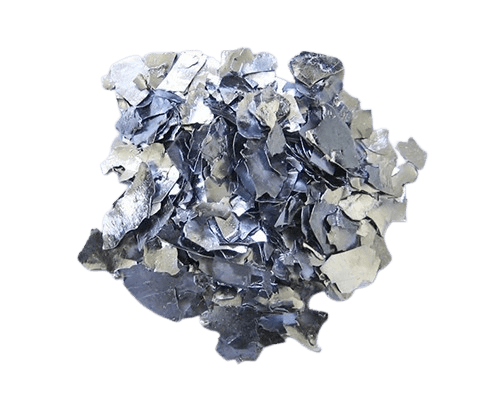

MetalsTek Engineering is a leading supplier of Chromium Metals, including pieces, Pellets, Metals, and ingots.

Material: Chromium, CAS # 7440-47-3

Purity: Cr 99.8%, 99.95%, 99.98%, 99.99% or Cr Alloy

Density: 7.18 g/cc

Temperatures: 1,900°C M.P., 2,672°C M.P.

Shape: Pieces, Pellets, Ingots, Can be Customized

Size: 2mm/3mm/6mm Pellets, or Customized Sizes

Material: Chromium, CAS # 7440-47-3

Purity: Cr 99.8%, 99.95%, or Cr Alloy

Density: 7.18 g/cc

Temperatures: 1,900°C M.P., 2,672°C M.P.

Type: Spherical Powder, Nano Powder, Degassed Electrolytic

Particles: Various, Can be Customized

Material: Chromium

Purity: Cr 99.95%

Grade: ECR001, ECR002

Properties: Silvery White, Non-toxic, Odorless

| Chemical | Cr % | C | S | O | N | Fe |

| ECR001 | ≥99.95 | ≤100 | ≤30 | ≤50 | ≤50 | ≤70 |

| ECR002 | ≥99.95 | ≥100 | ≥30 | ≥200 | ≥50 | ≥70 |

Chromium is a lustrous, hard, and brittle transition metal with a blue-silvery white color, known for its high corrosion resistance and high melting point. It is used in various forms, such as chromium rods, sheets, and tubes, for applications in industries like aerospace, automotive, chemical manufacturing, and electronics. Chromium’s physical properties include a high melting point (2,180 K), a boiling point of 2,944 K, and a density of 7.18 g/cm³. It is the most rigid metallic element in the periodic table and is used in stainless steel and chrome plating, comprising 85% of its commercial use. Chromium is also valued for resisting tarnishing and reflecting light, making it ideal for polished surfaces and mirrors.

| Composition | Cr | Fe | Al | Si | Cu | S | C | O | N | Pb | P |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | 99.95 | 0.025 | 0.0048 | 0.0037 | <0.005 | ≤0.005 | ≤0.02 | ≤0.10 | ≤0.03 | ≤0.001 | <0.005 |

Chromium, a versatile metal, finds a wide range of applications across various industries due to its unique properties. Some critical applications of chromium include:

1. Stainless Steel Production: Chromium is a crucial alloying element in stainless steel manufacturing. It enhances stainless steel’s corrosion resistance, strength, and durability, making it suitable for construction, automotive, aerospace, and household appliance applications.

2. Decorative Plating: Chromium plating, also known as chrome plating, is widely used for decorative purposes in automotive trim, faucets, lighting fixtures, and household appliances. Chromium’s lustrous appearance and corrosion resistance make it ideal for enhancing the aesthetic appeal of metal surfaces.

3. Corrosion Protection: Chromium is used in various corrosion-resistant coatings, such as chromate conversion and passivation treatments, to protect metal surfaces from corrosion and oxidation. These coatings extend the service life of aerospace, automotive, and marine components.

4. Hard Chrome Plating: Chromium is employed in hard chrome plating processes to provide wear resistance, hardness, and lubricity to metal components such as hydraulic cylinders, piston rods, and industrial machinery parts. Hard chrome plating enhances the durability and performance of critical engineering components.

5. Alloy Production: Chromium is an alloying element that produces specialized alloys, such as Nichrome (nickel-chromium) and Ferrochrome (iron-chromium). These alloys are utilized in electrical heating elements, high-temperature applications, and stainless-steel production.

6. Refractory Materials: Chromium oxide (Cr2O3) produces bricks and linings for high-temperature furnaces, kilns, and reactors. Chromium-based refractories offer excellent thermal stability, mechanical strength, and resistance to chemical corrosion.

7. Chemical Catalysts: Chromium compounds are catalysts in various chemical processes, including polymerization, oxidation, and hydrogenation reactions. They are used to produce plastics, pharmaceuticals, and fine chemicals.

8. Electroplating Industry: Chromium is extensively used in the electroplating industry for depositing protective and decorative coatings on metal substrates. Chromium electroplating provides corrosion resistance, hardness, and a shiny finish to metal surfaces.

9. Aerospace and Defense: Chromium is employed in aerospace and defense applications for coating turbine blades, aircraft components, and military equipment to enhance their resistance to high temperatures, wear, and corrosion in demanding operating environments.

10. Dye and Pigment Production: Chromium compounds produce pigments and dyes for applications in paints, inks, and textiles. Chromium-based pigments offer vibrant colors, UV stability, and resistance to fading, making them valuable in various industries.

These diverse applications underscore the significance of chromium in modern industrial processes. Its unique properties enhance performance, durability, and functionality across various products and sectors.

Our Chromium Metals are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent damage during storage or transportation.