Menu

Material: 1075 Spring Steel

Shape: Sheet

Standard: SAE AMS5122/ASTM A682, ASTM A 684

Main Applications: Snap Springs, Lock Springs, Trap Springs, etc.

Material: AISI 1095 Spring Steel

Shape: Sheet Roll

Standard: ASTM A682, ASTM A684, MIL-S-7947

Main Applications: Vehicle Coil Springs, Spring Clamps, Antennas, S-Tines, Lock Picks, Clock Hands

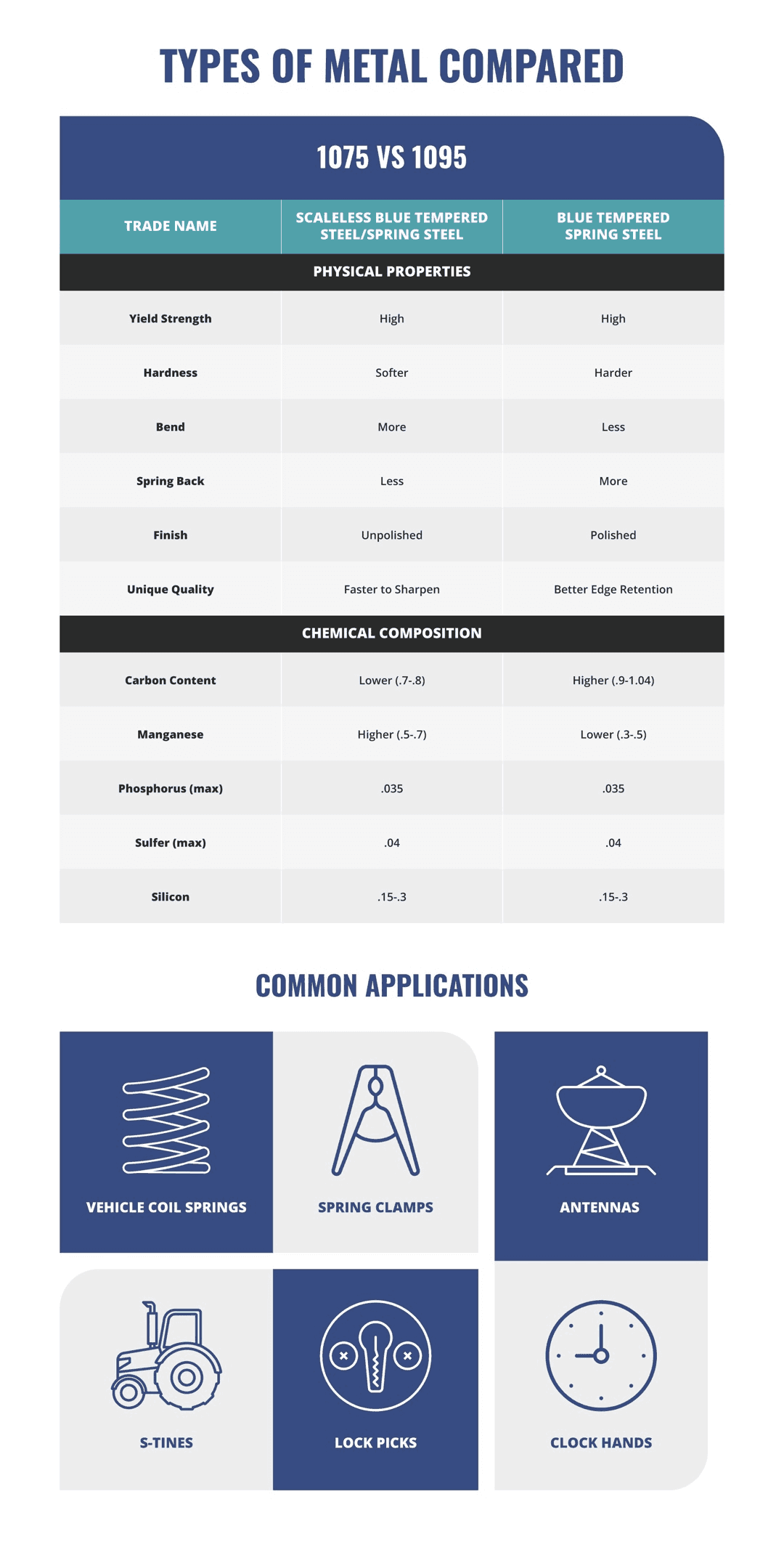

Spring steel is a specialized type of steel used for making springs and elastic components. It boasts high yield strength and elasticity, enabling it to revert to its original shape after deformation. This steel is vital in applications requiring resilience and durability, including automotive suspensions, mechanical springs, and hand tools.

| Width (inch) | Length (inch) | Thickness (inch) | Thick. Tolerance | Min. Hardness |

| 1 1/2 | 25 | 0.125 | ±0.002 | SAE AMS5122 |

| 4 | 25 | 0.094 | ±0.002 | SAE AMS5122 |

| 24 | 48 | 0.025 | ±0.001 | ASTM A682 ASTM A684 |

| 0.032 | ±0.0015 | |||

| 0.035 | ±0.002 | |||

| 0.042 | ±0.002 | |||

| 0.05 | ±0.002 | |||

| 0.062 | ±0.002 |

1095 Spring Steel Descriptions

1095 spring steel is a high-carbon steel alloy known for its excellent strength, hardness, and elasticity, making it well-suited for various industrial and consumer applications such as springs and cutting tools. It is a versatile and high-performance material.

1095 Spring Steel Features