Menu

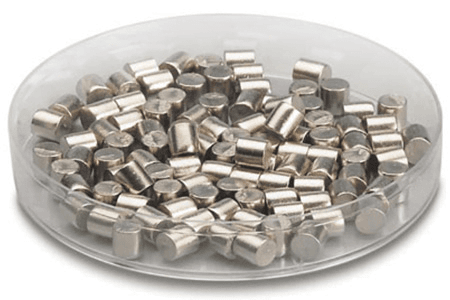

MetalsTek Engineering is a leading manufacturer and supplier of high-purity Indium Evaporation Materials, offering a wide variety of options to meet the needs of thin-film deposition processes in industries ranging from electronics to photovoltaics.

Material: Indium

Purity: In 99.9%~99.999%

Form: Pellets, Granule, Powder, Can be Customized

Size: 2*2mm, 3*3mm, or Tailored Sizes

Main Applications: Semiconductor Deposition, CVD, PVD, Optics Coatings

Material: Indium

Purity: Cu/In 99.9%~99.999%

Form: Pellets, Granule, Powder, Can be Customized

Main Applications: Semiconductor Deposition, CVD, PVD, Optics Coatings

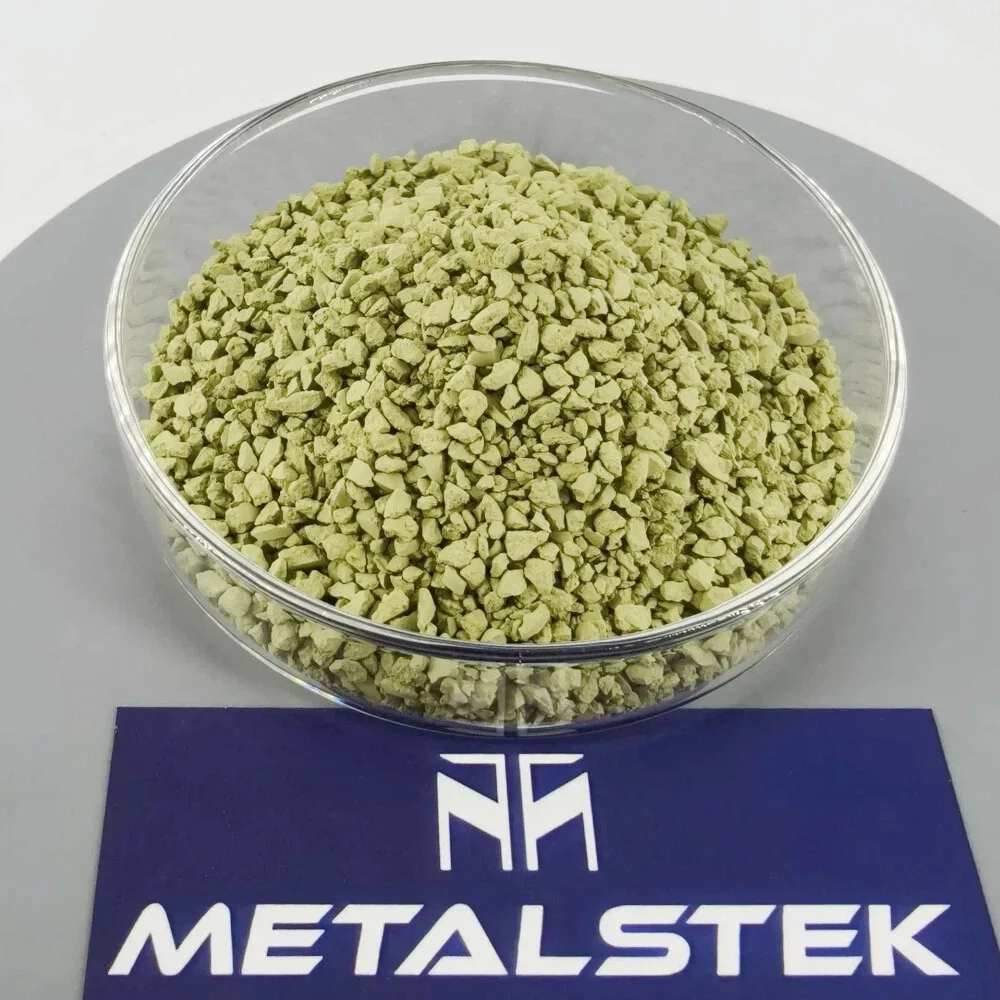

Material: Indium Tin Oxide

Purity: In-Sn-O 99.99%

Properties: 7.2g/cc Density, ~1,850°C M.P.

Form: Granule, Powder, Can be Customized

Main Applications: Semiconductor Deposition, Optoelectronics, Photovoltaics

Material: Indium Zinc Oxide

Purity: In-Zn-O 99.99%

Properties: 7.2g/cc Density, ~1,850°C M.P.

Form: Granule, Powder, Can be Customized

Main Applications: Semiconductor Deposition, Optoelectronics, Photovoltaics

Material: Copper Indium Gallium

Purity: Cu-In-Ga 99.99%

Form: Granule, Pieces, Can be Customized

Main Applications: On Solar Cells to Form Photovoltaic

Indium’s properties, such as its low melting point, density, and thermal conductivity, make it suitable for thin-film deposition processes. It is a soft and metallic-gray metal with a density of 7.3 g/cc and a melting point of 157°C. Indium can be deposited via E-beam or thermal evaporation methods, with E-beam evaporation being rated excellent for this material. Indium, which can cling to glass surfaces, is utilized in various applications, including producing electronics and photovoltaic cells through thermal evaporation. MetalsTek Engineering offers high-purity Indium and Indium Related pellets and pieces for evaporation materials, which are commonly used in thin-film deposition processes.

Material Type | Indium | Z Ratio | 0.841 |

Symbol | In | E-Beam | Excellent |

Atomic Weight | 114.818 | Thermal Evaporation Techniques | Boat: W, Nb Basket: W Crucible: Al2O3 |

Atomic Number | 49 | E-Beam Crucible Liner Material | FABMATE®, Graphite, Molybdenum |

Color/Appearance | Silvery Lustrous Gray, Metallic | ||

Thermal Conductivity | 82 W/m.K | Temp. (°C) for Given Vap. Press. (Torr)

| 10-8: 487 |

10-6: 990 | |||

10-4: 1,200 | |||

Melting Point | 157 °C | Comments | Wets W and Cu. Use Mo liner. Low Melting Point materials not ideal for sputtering. |

Coefficient of Thermal Expansion | 32.1 x 10-6/K | ||

Theoretical Density | 7.3 g/cc | Suggested QCM Crystal | Alloy Crystal: 750-1002-G10**** |

Indium Evaporation Materials find widespread use across various industries due to indium’s unique properties and benefits. Here are some critical applications:

1. Semiconductor Fabrication: Indium is commonly used in semiconductor manufacturing processes for applications such as forming ohmic contacts, creating transparent conductive coatings (e.g., indium tin oxide, or ITO), and bonding semiconductor components. In these applications, indium evaporation materials deposit thin films with precise thickness and uniformity, contributing to the performance and functionality of semiconductor devices.

2. Flat Panel Displays: Indium tin oxide (ITO) thin films deposited using indium evaporation materials are integral components of flat panel displays, including LCDs, OLEDs, and touchscreens. ITO coatings provide transparency, conductivity, and scratch resistance, making them essential for electrode and transparent conductive layer applications in display technologies.

3. Solar Cell Manufacturing: Indium gallium arsenide (InGaAs) and copper indium gallium selenide (CIGS) are semiconductor materials used in photovoltaic solar cell technology. Indium evaporation materials deposit thin films of these materials onto substrates, enabling the conversion of solar energy into electricity in solar cell devices.

4. Optoelectronics: Indium-based thin films are utilized in various optoelectronic devices, including photodetectors, LEDs (light-emitting diodes), and laser diodes. Indium evaporation materials play a crucial role in depositing the active layers and electrodes required to operate these devices, enhancing their performance and efficiency.

5. Transparent Conductive Coatings: Beyond display technologies, indium-based thin films are used as transparent conductive coatings in applications such as bright windows, antistatic coatings, and electromagnetic interference (EMI) shielding. These coatings provide electrical conductivity and optical transparency, making them suitable for diverse applications in electronics and optics.

6.Thin Film Deposition Research: Research and development laboratories also utilize indium evaporation materials for thin film deposition studies and experiments. Researchers investigate novel materials, deposition techniques, and device architectures using indium evaporation materials to advance scientific understanding and technological innovation.

Our Indium Evaporation Materials are labeled externally to ensure efficient identification and quality control. We take great care to prevent any damage during storage or transportation.