Menu

MetalsTek Engineering is a leading supplier in the manufacturing and distribution of high-purity Iridium Evaporation Materials and a wide range of other evaporation materials. Our products are available in powder and granule formats, and we offer customization options upon request.

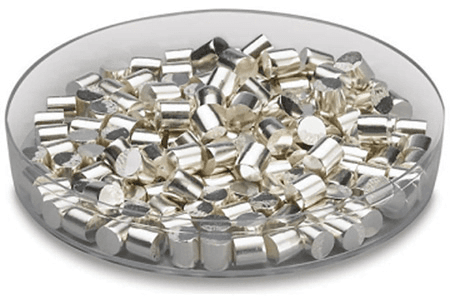

Material: Iridium, Ir

Purity: Ir 99.99%

Properties: Silvery White Metallic, 22.42g/cc Density, 2,410°C M.P.

Form: Pieces, Pellets, Can be Customized

Size: Tailored Sizes

Iridium is a rare metal that falls under the platinum elements in the Periodic Table. Its unique characteristics include a high melting point of 2,410°C, a density of 22.42 g/cc, and a vapor pressure of 10-4 Torr at 2,380°C. Its silvery-white appearance and exceptional corrosion resistance make it a popular strengthening component in platinum alloys. It is also used in equipment designed for extreme heat conditions. Vacuum evaporation processes create particle and surface modification coatings, data storage devices, and fuel cells with iridium.

Material Type | Iridium | Z Ratio | 0.129 |

Symbol | Ir | E-Beam | Fair |

Atomic Weight | 192.217 | Thermal Evaporation Techniques | Boat: W, Nb Basket: W Crucible: Al2O3 |

Atomic Number | 77 | Temp. (°C) for Given Vap. Press. (Torr)

| 10-8: 487 |

Color/Appearance | Silvery White, Metallic | ||

Thermal Conductivity | 150 W/m.K | ||

10-6: 990 | |||

Melting Point | 2,410 °C | ||

Coefficient of Thermal Expansion | 6.4 x 10-6/K | 10-4: 1,200 | |

Theoretical Density | 22.42 g/cc |

Iridium Evaporation Materials are crucial in the field of thin-film deposition, including semiconductor deposition, chemical vapor deposition (CVD), and physical vapor deposition (PVD), and they play a significant role in the advancement of various high-tech applications.

Our Iridium Evaporation Materials are labeled externally to ensure identification and quality control. We take great care to prevent damage during storage or transportation.