Menu

MetalsTek Engineering offers exceptional Rhodium Sputtering Targets that represent the highest standards of purity and precision in the semiconductor, electronics, and optical industries. Our advanced manufacturing techniques ensure superior performance and innovation in your coating processes, keeping your products at the forefront of technological progress. Count on MetalsTek Engineering for excellence in materials and engineering.

Material: Rhodium

Purity: Ru 99.95%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Size Ranges: Disc – Dia. ≤14” * Thick≥1mm; Block – Thick≥1mm * Width ≤12” * Length≤32”

Bonding: Indium, Copper or Elastomer Bonding Recommended

Main Applications: Electronics, Semiconductors, Flat Panel Displays

Rhodium Sputtering Targets are important components used in various advanced technologies such as optics, semiconductors, and magnetic storage media. Rhodium, which is a rare silvery-white metal, is valued for its exceptional hardness, chemical inertness, and corrosion resistance properties. These sputtering targets are manufactured with high purity levels, typically around 99.95%, to ensure optimal performance in sputtering processes. Rhodium Sputtering Targets play a crucial role in deposition processes, enabling the creation of precise and high-quality thin films that are essential for various industrial applications in cutting-edge technology sectors.

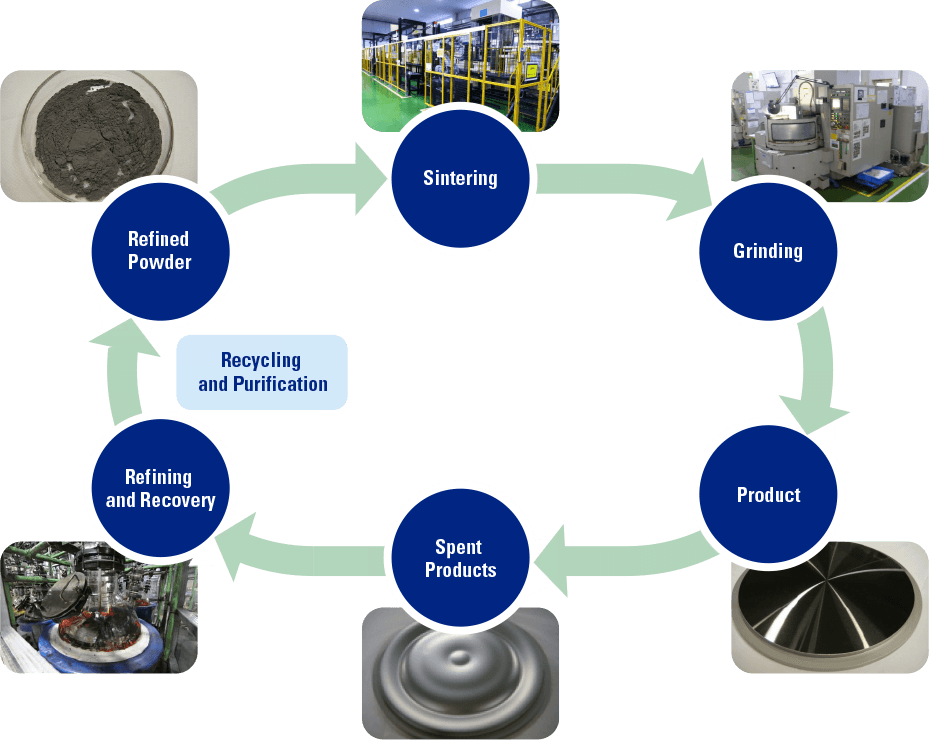

Refining: Three-layer electrolytic process

Melting and casting: Electrical resistance furnace – Semi-continuous casting

Grain refinement: Thermomechanical treatment

Cleaning and final packaging: Cleaned for use in vacuum; Protection from environmental contaminants; Protection during shipment

Rhodium Sputtering Targets have a range of specialized applications across various industries, primarily due to Rhodium’s exceptional properties, such as high reflectivity, excellent corrosion resistance, and superior chemical stability. Here are some of the critical applications:

These applications underscore the versatility and importance of Rhodium Sputtering Targets in advancing technology and improving the quality of products in numerous sectors.

Our Rhodium Sputtering Targets are vacuum sealed and been clearly labeled externally to ensure efficient identification and quality control. To prevent any damage during storage or transportation, we take great care.