Menu

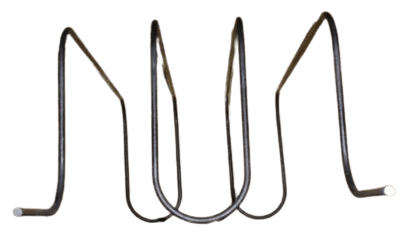

MetalsTek Engineering is a professional supplier of Molybdenum Heating Elements and has extensive experience in manufacturing high-performance heating elements, particularly molybdenum and its alloys. There are different shapes for the Moly heaters, such as W, U, and O. The shapes and sizes can also be customized.

There are different shapes for the Moly heaters, such as W, U, and O. The shapes and sizes can also be customized.

Material: Molybdenum, Mo-1 / Mo-2

Purity: Mo 99.95% Min

Density: 10~10.2 g/cc

Standard: ASTM B387, ASTM B386

Shape: Tailored Shape, Per Drawing

Size: Dia. 3~12 mm, Can be Customized

| Diameter (mm) | Width (mm) | Height (mm) | |||

|---|---|---|---|---|---|

| Size | Tolerance | Size | Tolerance | Size | Tolerance |

| 3 | ±0.1 | <650 | ±5.0 | <1200 | ±10.0 |

| 4 | ±0.1 | <600 | ±5.0 | <1150 | ±10.0 |

| 5 | ±0.1 | <550 | ±5.0 | <1100 | ±10.0 |

| 6 | ±0.2 | <550 | ±5.0 | <1050 | ±10.0 |

| 7 | ±0.2 | <500 | ±5.0 | <1000 | ±10.0 |

| 8 | ±0.2 | <500 | ±5.0 | <950 | ±5.0 |

| 9 | ±0.2 | <450 | ±5.0 | <900 | ±5.0 |

Material: Molybdenum Disilicide (MoSi2)

Model: MD-1700, MD-1800

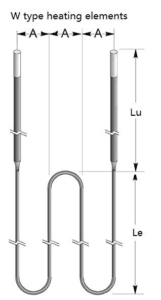

Shape: W Shape, Per Drawing

Size: Dia. 3, 4, 6, 9, 12mm for Hot Zone

| Model | Hot Zone (Le) | Cold End (Lu) | Distance (A) | |||

|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | |

| L36 | 3 | 0.12 | 6 | 0.24 | 25 | 0.98 |

| L48 | 4 | 0.16 | 9 | 0.35 | 25 | 0.98 |

| L612 | 6 | 0.24 | 12 | 0.47 | 50 | 1.97 |

| L918 | 9 | 0.35 | 18 | 0.71 | 60 | 2.36 |

| L1224 | 12 | 0.47 | 24 | 0.94 | 80 | 3.15 |

| All diameters are available in the following grades: | ||||||

| MD -1700 – maximum element temperature 1,700ºC (3,090ºF) | ||||||

| MD -1800 – maximum element temperature 1,800ºC (3,270º) | ||||||

Material: Molybdenum Disilicide (MoSi2)

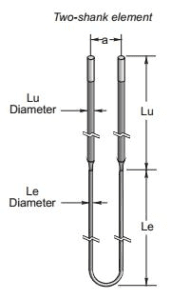

Model: MD-1700, MD-1800

Shape: U Shape, Per Drawing

Size: Dia. 3, 4, 6, 9, 12mm for Hot Zone

| Model | Hot Zone (Le) | Cold End (Lu) | ||

|---|---|---|---|---|

| mm | in | mm | in | |

| UL36 | 3 | 0.12 | 6 | 0.24 |

| UL48 | 4 | 0.16 | 9 | 0.35 |

| UL612 | 6 | 0.24 | 12 | 0.47 |

| UL918 | 9 | 0.35 | 18 | 0.71 |

| UL1224 | 12 | 0.47 | 24 | 0.94 |

| All diameters are available in the following grades: | ||||

| MD -1700 – maximum element temperature 1,700ºC (3,090ºF) | ||||

| MD -1800 – maximum element temperature 1,800ºC (3,270º) | ||||

Material: Molybdenum Disilicide (MoSi2)

Model: MD-1700, MD-1800

Shape: O Shape, Per Drawing

Size: Dia. 3, 4, 6, 9, 12mm for Hot Zone

Molybdenum Heating Elements are made from refractory metals, such as molybdenum and tungsten or alloys, ideally suited for high-temperature applications. They are used in various industries, including furnace construction, glass melting, and laboratory equipment—the max. The operating temperature for Molybdenum Heating Elements can be 1,900ºC.

The molybdenum heat shield consists of two riveted cylindrical shells of rolled molybdenum put into each other. Our sheet material is of the highest quality to ensure the expected performance within your furnace application.

Material: Molybdenum (Mo)

Mo≥99.95%

Density: 9.8~10.2 g/cc

Surface: Rolled, Chemical Cleaned

Other: Customized Model

Molybdenum Heating Elements are used in various applications due to their high-temperature resistance, strength, and stability. Some common applications include:

In summary, Molybdenum Heating Elements are used in various applications, including high-temperature furnaces, furnace construction, vacuum furnace applications, laboratory equipment, and glass melting, due to their high-temperature resistance, strength, and stability

Our Molybdenum Heating Elements & Shield are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.