Menu

MetalsTek Engineering supplies high purity Molybdenum Powder, Micro Molybdenum Powder, Nano Molybdenum Powder, Plasma Spherical Molybdenum Powder, Thermal Spraying Molybdenum Powder and other Molybdenum compound powders.

Material: Molybdenum (Mo)

Purity: 99%, 99.5%, 99.8%, 99.9%, 99.95%

Density: 9.8~10.2 g/cc

Color: Gray Color

Particle Size: Wide Range, Tailored

CAS #: 7439-98-7

99%: Pb < 0.001%, Bi < 0.001%, Sn < 0.001%

99.5%: Pb < 0.0001%, Bi < 0.0001%, Sn < 0.0001%

| Molybdenum Power Compositions (PPM) | |||

|---|---|---|---|

| Grade | MP-1 | MP-2 | MP-3 |

| Mo≥ | 99.95% | 99.90% | 99.80% |

| Fe | 50 | 60 | 100 |

| Al | 15 | 20 | 50 |

| As | 10 | — | — |

| Ba | 10 | — | — |

| C | 40 | 75 | — |

| Ca | 20 | 20 | 50 |

| Co | 30 | — | — |

| Cr | 20 | 30 | — |

| Cu | 10 | 20 | 30 |

| K | 20 | — | — |

| Mg | 10 | 20 | 20 |

| Mn | 5 | 10 | — |

| Na | 10 | — | — |

| Ni | 10 | 20 | 10 |

| O | 500-1000 | 2000 | 2500 |

| P | 10 | 20 | — |

| Pb | 10 | 10 | — |

| S | 20 | — | — |

| Si | 10 | 30 | 200 |

| Ti | 10 | 10 | — |

| W | 100 | 300 | — |

Applications of Molybdenum Powder:

Molybdenum Powder Safety Information:

Flame Health Hazard: GHS02, GHS08

Signal Word: Danger

Hazard Statements: H228 – H361f

Precautionary Statements: P202 – P210 – P240 – P241 – P280 – P308 + P313

Storage Class Code: 4.1B – Flammable solid hazardous materials

WGK: nwg

Material: Molybdenum (Mo)

Purity: Mo 99.8%

Tap Density: ≥6.5 g/cc

Hall Flow Rate: 40s/50g

Rate of spheroidization: ≥98%

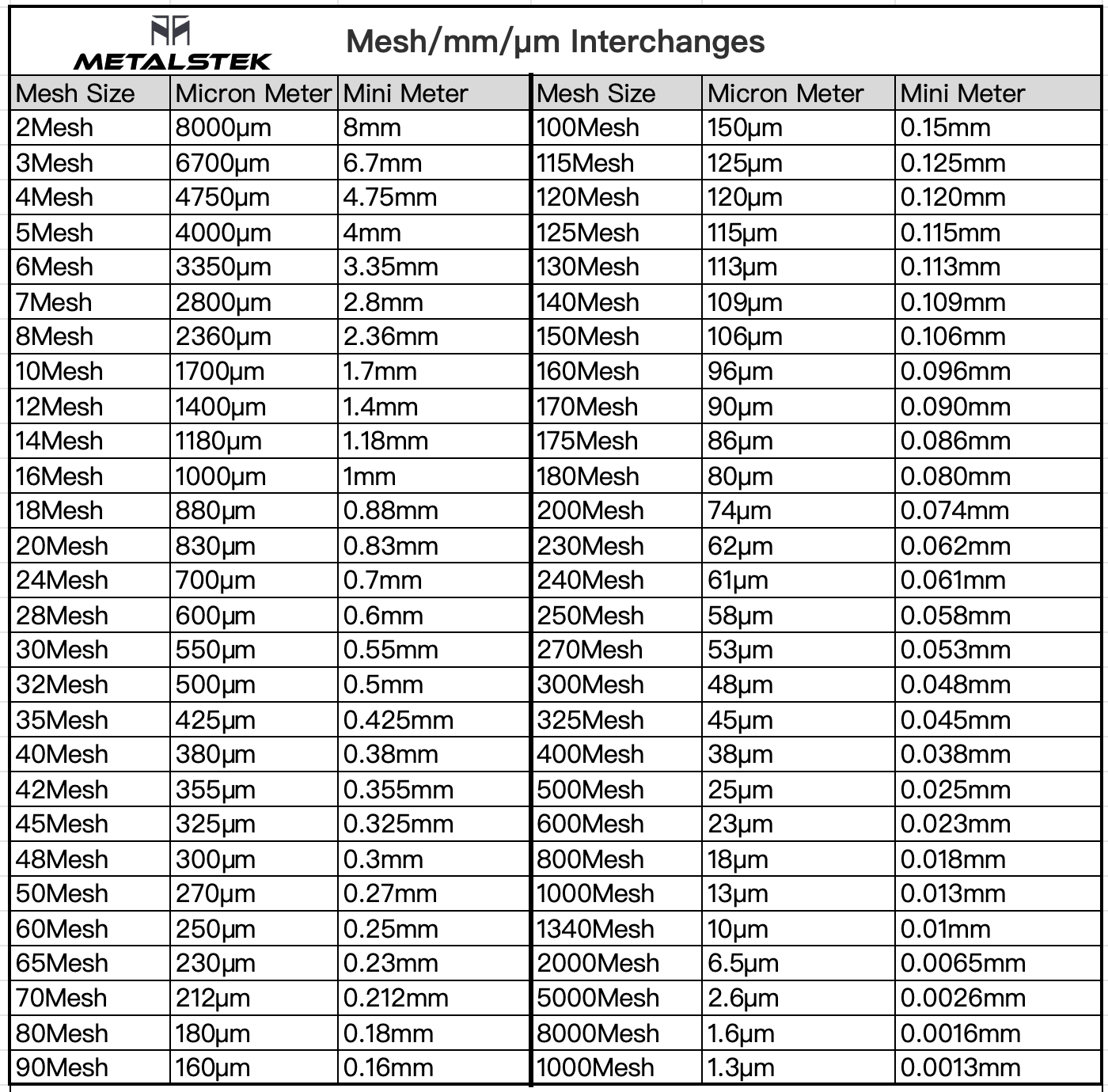

Particle Size: 15~150μm, Tailored

Main Impurities: O ≤ 300ppm, Ni≤10ppm

Applications: Spraying, Near-Net Molding, Injection Molding, Metallurgy, Targets

Material: Molybdenum (Mo)

Purity: ≥99.0%

Particle Size: 16~45μm (Agglomerated and Sintered)

30~75μm (Sintered and Crushed)

38~75μm (Agglomerated and Densified)

CAS #: 7439-98-7

Thermal spraying coatings typically use materials in the forms of powder, wire, or rod. These materials undergo heating, transforming into micrometer-sized particles. These particles are then propelled towards substrates, forming a coating.

In the automotive industry, Molybdenum Powder is frequently employed for thermal spraying, particularly in crafting engine pistons and synchronizer rings. This choice is driven by molybdenum’s advantageous characteristics, including a low friction coefficient, high resistance to sliding wear, and ductility. Molybdenum coatings deliver favorable frictional properties and scuff resistance, thanks to a promptly formed, adherent oxide surface layer post-spraying. Furthermore, these coatings exhibit hardness and lubricious qualities, ensuring excellent performance in dry conditions.

Material: Molybdenum (Mo)

Purity: ≥99.9%

APS: 60 nm

Surface Area: 10 m2/g

Tap Density: 3.39 g/cc

CAS#: 7439-98-7

Molybdenum nanoparticles find a range of applications in both traditional and high-tech industries, including mechanics, electronics, aeronautics, metallurgy, chemistry, and environmental sectors. Nano molybdenum powder, characterized by individual particle granularity, maintains excellent stability in room temperature air, forming approximately spherical particles. It boasts a high specific surface area, high activity during sintering, and impressive strength, hardness, thermal conductivity, and corrosion resistance at elevated temperatures.

Nano Molybdenum Powder Applications

1 Metal additive: Add in stainless steel, 1-4% of nano powder, Molybdenum can enhance stainless steel corrosion in corrosive environment capacity.

2 Nano molybdenum powder is also applied to electronic industrial manufacture high power vacuum tubes, magnetrons, heating tubes, X-ray tubes, and medical applications.

Material: Molybdenum (Mo)

Purity: ≥99.9% (98% Minimal)

APS: 1~2 μm

Surface Area: 4 m2/g

Tap Density: 3.39 g/cc

CAS#: 7439-98-7

Applications: Mechanics, Electronics, Aeronautics, Metallurgy, Chemistry, Environment

Molybdenum Powder is a gray metallic transition metal with a Mohs hardness of 5.5, produced through methods like reducing molybdenum trioxide or ammonium molybdate. Its high purity, often exceeding 99.98%, and fine particle size of around 1-2 microns APS makes it a versatile material with unique properties. Some key characteristics include a melting point of 2,610°C, a boiling point of 5,560°C, and a density of 10.2 g/cc.

Molybdenum powder must be kept in cool dry conditions, stays unpressed. Our molybdenum powder is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to preserve the quality of the product in its original condition.