Menu

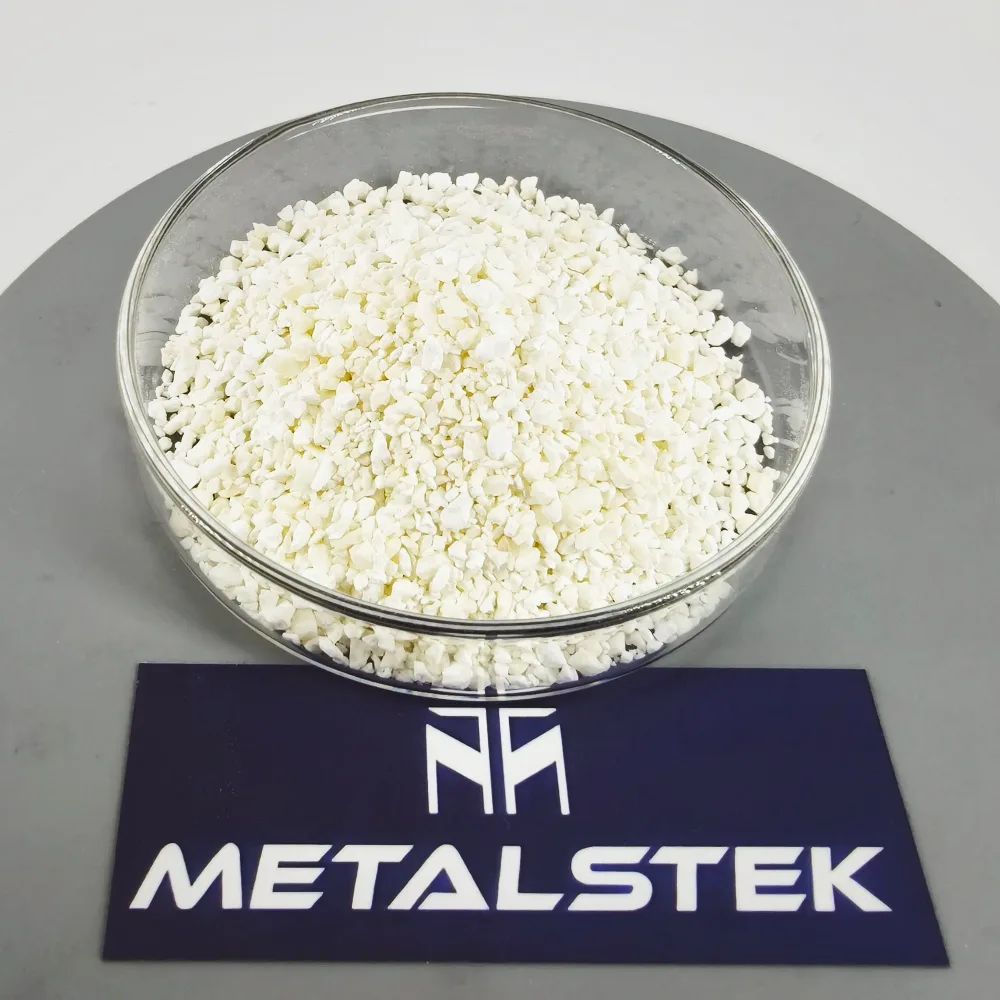

MetalsTek Engineering is a premier manufacturer and provider of high-purity Niobium Evaporation Materials and an extensive range of evaporation materials. Our offerings include evaporation materials in powder and granule formats, with the flexibility for customization upon request.

Purity: 99.9%~99.99%

Density: 8.57 g/cc

Melting Point: 2,468 °C

Thermal Conductivity: 54 W/m.K

Thermal Expansion: 7.3 x 10-6/K

Shape: Pellets, Granules, Powder, or Customized

Purity: 99.9%~99.95%

Density: 4.6 g/cc

Melting Point: 1,485 °C

Shape: Pellets, Granules, Powder, or Customized

Application: Semiconductor Deposition, CVD, PVD, Optics, Decorative Coatings

Purity: 99.5%, 99.9%

Density: 8.47 g/cc

Melting Point: 2,522 °C/ 4,552 °F

Shape: Pellets, Granules, Powder, or Customized

Application: Super Conductor, Semiconductors, Quantum Computing, Solar Cell Coating, Sensors, Optoelectronics

Purity: 99.5%

Density: 7.82 g/cc

Melting Point: 3,608 °C (6,526 °F; 3,881 K)

Shape: Granules, Powder, or Customized

Application: Semiconductors, Quantum Computing, Solar Cell Coating, Sensors, Optoelectronics

Purity: 99.5%

Density: 6.97 g/cc

Melting Point: 2,270 °C

Shape: Granules, Powder, or Customized

Application: Semiconductors, Quantum Computing, Solar Cell Coating, Sensors, Optoelectronics

Purity: 99.5%

Density: 5.53~5.7 g/cc

Melting Point: 1,950 °C

Shape: Granules, Powder, or Customized

Application: Semiconductors, Quantum Computing, Solar Cell Coating, Sensors, Optoelectronics

Purity: 99.9%~99.999%

Density: 6.3 g/cc

Melting Point: 1,300 °C

Shape: Granules, Powder, or Customized

Application: Semiconductors, Quantum Computing, Solar Cell Coating, Sensors, Optoelectronics

Purity: 99.9%~99.999%

Shape: Granules, Powder, or Customized

Application: Semiconductors, Quantum Computing, Solar Cell Coating, Sensors, Optoelectronics

Niobium Evaporation Materials refer to substances composed of niobium and its compounds designed for use in physical vapor deposition (PVD) or thermal evaporation. PVD is widely employed in thin film deposition for various applications, including coatings, semiconductor manufacturing, and optics. Niobium, a transition metal, exhibits unique properties that make it suitable for specific applications in thin film deposition.

MetalsTek Engineering is a premier manufacturer and provider of high-purity Niobium Evaporation Materials and an extensive range of evaporation materials. Our offerings include evaporation materials in powder and granule formats, with the flexibility for customization upon request.

Material Type | Niobium | Z Ratio | 0.492 |

Symbol | Nb | E-Beam | Excellent |

Atomic Weight | 92.90638 | E-Beam Crucible Liner Material | FABMATE® |

Atomic Number | 41 | ||

Color/Appearance | Gray, Metallic | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 1,728 |

10-6: 1,977 | |||

10-4: 2,287 | |||

Thermal Conductivity | 54 W/m.K | Comments | Attacks W source. |

Melting Point | 2,468 °C | ||

Coefficient of Thermal Expansion | 7.3 x 10-6/K | ||

Theoretical Density | 8.57 g/cc |

Niobium evaporation materials find diverse applications in various industries, leveraging their unique properties for thin film deposition. Some notable applications include:

These applications highlight the versatility of niobium evaporation materials across various industries, showcasing their importance in advancing technology, research, and manufacturing processes.