Menu

Material: Tantalum or Tantalum Alloys

Grade: R05200, R05400, R05252 (Ta-2.5W), R05255 (Ta-10W), R05240 (Ta-40Nb)

Purity: >99.9%

Standard: ASTM B708

Surface: Polished, Finish Turning

Material: Tantalum or Tantalum Alloys

Grade: Ta>99.9%, R05200, R05400, R05252 (Ta-2.5W), R05255 (Ta-10W), R05240 (Ta-40Nb)

Lid: With or Without

Standard: ASTM B708

Surface: Polished, Finish Turning

MetalsTek Engineering offers Tantalum Crucibles, including those with round mouths, tapered designs, ellipses, and bottomless configurations, for various applications. These crucibles are designed to withstand high temperatures and corrosive environments, making them suitable for metallurgy, rare earth smelting, monocrystalline silicon production, solar energy, artificial crystals, and mechanical processing industries. Customization options are available based on customer specifications and requirements.

With over a decade of industry experience, MetalsTek can help you save time and costs with quality and cost-effective Tantalum Crucibles.

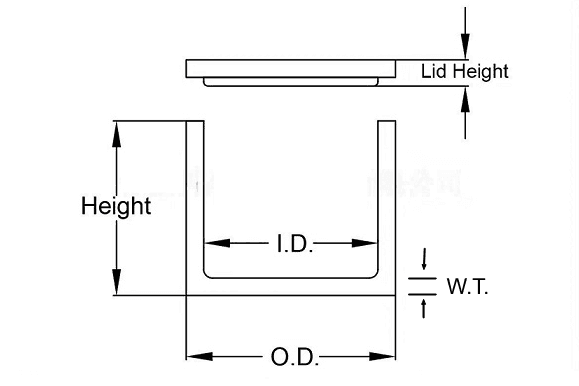

| ITEM NO. | CAPACITY | OD | ID | DEPTH | Tolerances |

|---|---|---|---|---|---|

| (mL) | (mm) | (mm) | (mm) | ||

| TAC-891000 | 1000 | 127 | 125.5 | 89 | OD: ±10 % |

| TAC-450100 | 100 | 59 | 58 | 45 | |

| TAC-410075 | 75 | 51 | 50 | 41 | ID: ±10 % |

| TAC-410055 | 55 | 47 | 46 | 41 | |

| TAC-340045 | 45 | 46 | 45 | 34 | DPT: ±10 % |

| TAC-290035 | 35 | 46 | 45 | 29 | |

| TAC-220025 | 25 | 45 | 44 | 22 | |

| TAC-290020 | 20 | 33 | 32 | 29 | |

| TAC-220015 | 15 | 33 | 32 | 22 | |

| TAC-220010 | 10 | 27 | 26 | 22 | |

| TAC-180005 | 5 | 21 | 20 | 18 | |

| Tantalum Crucible material, shape and size can be customized per requests. | |||||

| Diameter | Thickness | Height |

|---|---|---|

| (mm) | (mm) | (mm) |

| 30 ~ 50 | 2 ~ 10 | 30 ~ 500 |

| 50 ~ 100 | 3 ~ 15 | 30 ~ 500 |

| 100 ~ 150 | 3 ~ 15 | 30 ~ 500 |

| 150 ~ 200 | 5 ~ 20 | 30 ~ 500 |

| 200 ~ 300 | 8 ~ 20 | 30 ~ 500 |

| 300 ~ 400 | 8 ~ 30 | 30 ~ 500 |

| 400 ~ 450 | 8 ~ 30 | 30 ~ 500 |

| 450 ~ 500 | 8 ~ 30 | 30 ~ 500 |

Tantalum Crucibles find applications in various industries due to their high-temperature and corrosion resistance properties. Some notable applications include:

The specific applications may vary depending on industry requirements and the customization of crucibles to meet those needs.

Our Tantalum Crucible are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Tantalum crucibles may not be the first thing that comes to mind when considering cutting-edge technology, but their role in aerospace, semiconductors, and advanced manufacturing is vital. These robust crucibles can withstand extreme temperatures and corrosive environments that would break down most materials. Are you curious how such a small component can have a massive impact? In this article, we’ll delve into the fascinating properties, surprising applications, and reasons why tantalum crucibles are indispensable for some of the world’s most demanding processes.

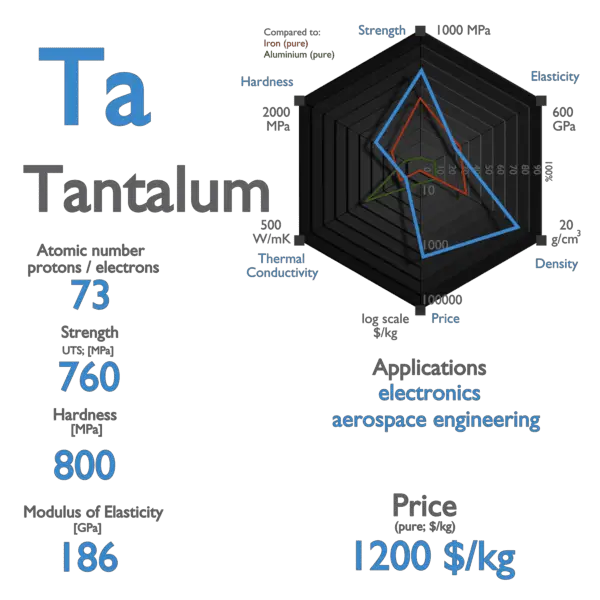

A tantalum crucible is a specialized container made from a rare and corrosion-resistant metal. Tantalum crucibles are predominantly utilized in high-temperature applications, particularly in metallurgy and materials science. Their primary function is to hold materials that require melting or processing at elevated temperatures. The properties of tantalum, including its high melting point of approximately 3,000 °C (5,432 °F) and its excellent resistance to chemical attack, make tantalum crucibles essential for these applications.

The unique characteristics of tantalum are what set it apart from other metals. High-purity tantalum crucibles, which can achieve a purity level of up to 99.95%, are often used in environments where contamination could compromise the desired outcomes. For instance, in the semiconductor industry, where even trace impurities can ruin processes, these custom tantalum crucibles provide the necessary assurance of purity and reliability. Moreover, due to the need for precise thermal management, seamless tantalum crucibles for laboratory use are particularly favored, as they minimize thermal gradients and ensure uniform heating.

In addition to their use in metallurgy, tantalum crucibles have several applications in the growing field of nanotechnology, as they can withstand the extreme conditions required for synthesizing novel materials. Tantalum e-beam crucibles are designed explicitly for electron beam melting, allowing for the production of high-quality material under controlled conditions. Furthermore, their corrosion resistance enables tantalum crucibles to be used in chemical environments where traditional materials would fail.

In summary, tantalum crucibles are indispensable in various high-temperature processes across multiple industries. Their unique properties enable them to perform effectively in demanding conditions, making them a preferred choice for researchers and manufacturers alike. For those looking to source tantalum crucibles, there are options available to buy tantalum crucibles online that meet various specifications, ensuring accessibility to these essential tools.

Tantalum is a highly coveted element in the metallurgical field due to its exceptional properties, contributing to its viability as a material for high-purity tantalum crucibles. One of the most significant characteristics of tantalum is its remarkably high melting point, which stands at approximately 3,017 degrees Celsius (5,477 degrees Fahrenheit). This high melting point makes tantalum crucibles particularly suitable for processes that involve melting metals and other materials at elevated temperatures. For instance, tantalum crucibles for melting are widely used in various applications, ranging from aerospace to semiconductor fabrication.

Another defining property of tantalum is its outstanding corrosion resistance. Tantalum exhibits remarkable inertness, allowing it to withstand aggressive chemical environments without degrading. This feature is especially beneficial in laboratory settings where seamless tantalum crucibles can be employed to prevent contamination during critical experimental procedures. The material’s resistance to a wide ramaterial’sds, including sulfuric and hydrochloric acid, further emphasizes its importance in industries that rely on chemical processing.

Regarding thermal conductivity, tantalum’s ability to efficiently tantalums makes it an excellent choice for applications requiring precise temperature control. This property is essential in producing high-purity materials, as consistent heating ensures uniformity and quality. Therefore, corrosion-resistant tantalum crucibles are often utilized in high-tech applications where the purity of materials is paramount, such as in producing semiconductor components.

In conclusion, tantalum’s unique combination of htantalum’sg point, excellent corrosion resistance, and efficient thermal conductivity make it an ideal material for various crucible applications. Whether seeking to buy tantalum crucibles online or considering custom tantalum crucibles for specialized processes, understanding the properties of tantalum is crucial for making informed decisions in metallurgy and beyond.

Selecting the appropriate tantalum crucible can significantly impact the efficiency and effectiveness of your processes. A high-purity tantalum crucible is often a preferred choice for various applications due to its remarkable resistance to corrosion and ability to withstand extreme temperatures. When choosing the proper crucible, several factors must be considered, including size, shape, thickness, and specific application requirements.

The size of the tantalum crucible is crucial as it must accommodate the volume of material to be melted or processed. For instance, more minor, custom tantalum crucibles might be ideal for laboratory use, while more extensive options are suitable for industrial applications. Additionally, the shape of the crucible can influence the heating efficiency and the fluid dynamics of the melt. For processes requiring precision, a seamless tantalum crucible ensures that there are no weak points that could compromise the integrity of the material.

Thickness is another critical factor to consider when selecting a tantalum crucible. A thicker crucible may offer enhanced durability and thermal stability, making it appropriate for high-temperature applications like metallurgy. Conversely, more delicate tasks might benefit from thinner options, as they heat up more quickly. Understanding the specific demands of your application will enable you to choose the right thickness.

Compatibility with the materials being processed is also essential. Tantalum e-beam crucibles, for example, provide excellent performance for materials that require a non-reactive environment. Moreover, opting for a 99.95% pure tantalum crucible ensures minimal contamination and offers optimal melting conditions, enhancing the purity of the final product.

To sum up, choosing the appropriate tantalum crucible requires careful consideration of size, shape, thickness, and material compatibility, ensuring optimal performance and reliability across various applications.

Tantalum crucibles are essential in various industrial processes, particularly metallurgy and material science. Their unique properties, such as high melting point and excellent corrosion resistance, make them suitable for multiple applications. When exploring tantalum crucibles, it is essential to note the distinctions based on shape, size, and design tailored for specific uses.

The most common shapes for tantalum crucibles include round and square configurations. Round tantalum crucibles are frequently used due to their uniform heat distribution and efficient melting ability, making them ideal for high-purity crucible applications. On the other hand, square crucibles can be advantageous for applications where maximum space utilization is essential, offering a broader surface area for molten materials.

Tantalum crucibles can vary greatly in size, accommodating different quantities of metal or material to be melted. Small sizes are often preferred in laboratory settings, whereas larger crucibles might be required for industrial processes. Customized options are also available, allowing for tailored dimensions to meet specific requirements. Custom tantalum crucibles can be designed for both intricate laboratory experiments and large-scale manufacturing processes.

Furthermore, specific designs such as tantalum e-beam crucibles cater to the unique challenges presented in specialized applications. These designs enhance the performance and stability of the crucibles when exposed to extreme conditions. Seamless tantalum crucibles for laboratory use ensure minimal contamination and increase the integrity of experiments, which is essential for achieving high-purity results.

Understanding the various types of tantalum crucibles and their applications is crucial for selecting the right crucible for your specific needs. By carefully considering shape, size, and material properties, buyers can optimize their processes and ensure the highest efficiency in applications ranging from metallurgy to advanced research.

Tantalum crucibles are integral in various industries due to their unique properties, high melting points, and exceptional corrosion resistance. These features render them highly effective for metallurgy, electronics, and chemical processing applications. Understanding the specific uses of tantalum crucibles can significantly enhance operational efficiencies in these fields.

In metallurgy, high-purity tantalum crucibles are utilized significantly to melt and cast high-temperature materials such as specialty alloys and refractory metals. These crucibles’ seamless design ensures they can withstand the extreme conditions encountered during melting processes. Notably, tantalum Ta crucibles are preferred for producing high-performance materials requiring exceptional structural integrity, making them essential in the aerospace and automotive industries.

In electronics, tantalum crucibles are pivotal in producing capacitors and other electronic components. Their ability to handle high temperatures and resist oxidation is crucial when dealing with materials that require precise thermal management. In particular, tantalum e-beam crucibles are used in electron beam evaporation processes, critical for depositing thin films in semiconductor manufacturing.

Chemical processing also benefits from the use of corrosion-resistant tantalum crucibles. These crucibles are ideal for handling aggressive chemicals and reactive environments, providing safety and longevity in various chemical reactions. Industries that require precision and reliability in chemical processing, such as pharmaceuticals and petrochemicals, rely on custom tantalum crucibles that can be tailored to meet specific requirements.

Overall, tantalum crucibles are vital across multiple sectors, providing solutions that enhance product quality and operational efficiency. Their versatility and resilience make them one of the premier choices for manufacturers looking to optimize their processes and outputs.

There are several common misconceptions surrounding tantalum crucibles that can lead to confusion regarding their usage and reliability. One prevalent myth is that tantalum crucibles are overly fragile and cannot withstand high-temperature environments. In reality, tantalum possesses an exceptionally high melting point, approximately 3,017°C (5,467°F), making tantalum crucibles well-suited for applications in metallurgy, particularly for the melting of numerous metals and compounds. This durability is a key reason many industries utilize high-purity tantalum crucibles for critical processes.

Another misunderstanding is the perceived limitation of tantalum crucibles to specific applications. While it is true that these crucibles are often observed in high-tech environments, like semiconductor manufacturing and vacuum furnaces, the versatility of custom tantalum crucibles allows them to be adapted for various uses. From research laboratories to industrial settings, they are employed in processes requiring high purity and corrosion resistance levels, thus expanding their applicability beyond what many might consider.

Some individuals also believe that tantalum crucibles are not cost-effective due to the higher initial investment than traditional materials. However, the long-term benefits offered by a 99.95% pure tantalum crucible, such as reduced contamination risks and prolonged service life, can result in overall cost savings. Additionally, the seamless design of tantalum e-beam crucibles minimizes the chances of structural weaknesses, which enhances their performance in intense environments.

Finally, while it may be thought that these crucibles cannot be easily sourced, it is now convenient to buy tantalum crucibles online, making them accessible to a broader range of users. Understanding these aspects helps dispel the myths surrounding tantalum crucibles and highlights their advantages within various applications.

Tantalum crucibles are essential in various scientific and industrial applications due to their exceptional properties. Here, we address some common inquiries regarding the maintenance, longevity, compatibility, and troubleshooting of tantalum crucibles.

What is the lifespan of a high-purity tantalum crucible?

The longevity of a tantalum crucible largely depends on its conditions of use, including the temperature and the substances it comes into contact with. A well-maintained tantalum crucible for melting can last several years, mainly when utilized within its recommended temperature limits and in appropriate environments.

How should I maintain my seamless tantalum crucibles for laboratory use?

To extend the life of your corrosion-resistant tantalum crucibles, it is vital to follow proper maintenance protocols. These include cleaning after each use, avoiding sudden temperature changes, and ensuring that the crucible is free from contaminants that could lead to material degradation.

Is a custom tantalum crucible compatible with all substances?

While tantalum is known for its compatibility with various materials, it is not universally compatible. It is particularly resistant to acid corrosion but may react unfavorably with certain alkalis and high-temperature environments. Users should refer to material safety data sheets to verify compatibility.

What are common issues encountered with tantalum e-beam crucibles?

Common issues include premature wear, cracking, or distortion caused by improper handling or extreme thermal shocks. Regular inspections and appropriate usage practices are crucial in mitigating these potential problems.

For further information or to buy tantalum crucibles online, it is advisable to consult with reputable suppliers who can provide detailed specifications and recommendations tailored to your specific needs.

Tantalum crucibles play a pivotal role in various industrial applications due to their remarkable properties, especially high-purity tantalum crucibles sought after in metallurgy and electronics. The unique characteristics of tantalum, such as its high melting point and exceptional corrosion resistance, make tantalum crucibles an ideal choice for melting and processing high-temperature materials. Users can purchase tantalum crucibles online, ensuring access to seamless tantalum crucibles for laboratory use and custom tantalum crucibles tailored to specific requirements.

As the demand for precision in manufacturing and processing increases, the application of tantalum e-beam crucibles is becoming more prevalent. These crucibles provide enhanced thermal stability and purity levels of up to 99.95% for high-quality results in advanced material synthesis. The use of tantalum in crucibles for melting operations is expected to grow as industries strive for higher performance standards and reduced contamination in their processes.

In addition to current applications, future trends in materials science may significantly influence the development and use of tantalum crucibles. With advancements in technology, we anticipate improvements in manufacturing techniques that could lead to even higher purity levels and customized options. The ongoing research in metal alloying and composite materials may also open new avenues for combining tantalum with other elements, resulting in enhanced properties for specialized applications.

The increasing focus on sustainability and efficient resource utilization in manufacturing processes will likely propel the growth of corrosion-resistant tantalum crucibles. As industries seek eco-friendly alternatives, tantalum’s unique properties will become increasingly valuable. The future looks promising for tantalum crucibles as their significance in metallurgy and related fields continues to expand.

At MetalsTek, we take great pride in providing top-notch Tantalum Crucibles that meet the demanding requirements of today’s industries. Our dedication to quality and our capability to tailor targets to precise sizes and compositions positions us as the go-to choice for businesses looking to push boundaries and achieve greatness.