Menu

MetalsTek Engineering is a leading supplier of Tantalum products across the world, offering customers high-quality Tantalum Plates, Tantalum Bars, Tantalum Sheets, Tantalum Foil, Tantalum Ribbon and other tantalum products.

Material: Tantalum, Ta / Tantalum Alloy

Grade: R05200, R05400, R05252(Ta-2.5W), R05255(Ta-10W)

Purity: 99.9%, 99.95%, 99.99%

Standard: ASTM B708

Size Range: Thick 0.07~10mm * Width 30~1,000mm * Length 30~3,000mm

Other: Material, Size, and Surface Can be Customized

Material: Tantalum, Ta / Tantalum Alloy

Grade: R05200, R05400, R05252(Ta-2.5W), R05255(Ta-10W)

Purity: 99.9%, 99.95%, 99.99%

Standard: ASTM B365-98

Standard Sizes: 15*15*600mm, 20*20*1,000mm, 45*45*1,200mm, 60*60*1,500mm

Other: Material, Size, and Surface Can be Customized

Tantalum Plates and Bars, crafted from the rare and highly dense metal tantalum, stand out for their remarkable corrosion resistance and efficient thermal conductivity. This unique combination of properties renders tantalum plates versatile for various applications, including but not limited to lining columns, vessels, and vacuum furnace components. They find indispensable use in advanced fields like military satellites, cutting-edge medical technologies, semiconductors and electronics, defense, furnace parts, chemical processing equipment, and medical applications.

MetalsTek Engineering is a leading supplier of Tantalum products across the world, offering customers high-quality Tantalum Plates, Tantalum Bars, Tantalum Sheets, Tantalum Foil, Tantalum Ribbon and other tantalum products.

Our Tantalum Plate and Bar are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.

Tantalum is a metal that can be seamlessly integrated into both your smartphone and the jet engine that powers your flights. It is primarily available in the form of sheets, foils, and plates. In this guide, we will explore the specific properties of tantalum, its main uses, the different grades and production methods, price considerations, and safety aspects when using it in an industrial setting.

Tantalum, primarily used in the forms of sheets, foils, and plates, is a critical material in various industrial applications due to its unique properties. Here we dive deep into these properties, providing detailed insights that highlight why tantalum is so valuable in today’s high-tech and high-stress environments.

Physical Properties

Mechanical Properties

Chemical Properties

Thermal Properties

Coefficient of Thermal Expansion: Its coefficient of thermal expansion is relatively low (6.3 × 10^-6 per °C), which ensures that it remains stable under conditions of thermal cycling. This stability is crucial for applications in aerospace and electronics, where materials must maintain their shape and size despite drastic temperature changes.

Tantalum’s unique properties such as high melting point, excellent corrosion resistance, and good thermal conductivity make it invaluable in various industrial applications:

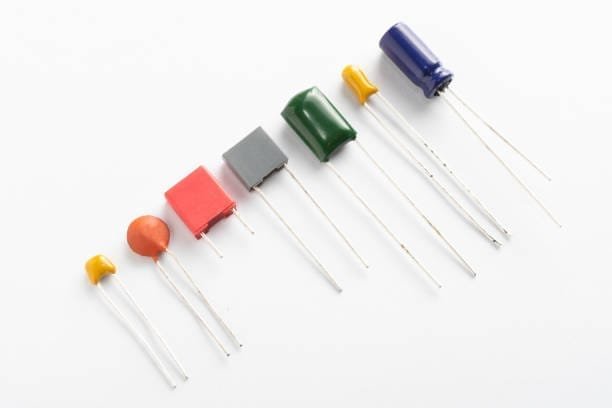

Electronics Industry

Aerospace and Aviation

Chemical Processing Industry

Medical Technology

Automotive Industry

Sensor and Control Systems: Tantalum sheets are utilized in manufacturing sensors and control systems within the automotive sector. These components benefit from tantalum’s stability and reliability under extreme operating conditions.

Manufacturing Tooling and Equipment

Optical and Photographic Equipment

Tantalum’s versatility in various industrial applications can be attributed not only to its exceptional properties but also to the diversity of its grades and the stringent standards that govern its production. Understanding these grades and standards is crucial for selecting the right type of tantalum for specific applications, ensuring compatibility, performance, and safety.

Common Tantalum Grades

R05252 (Tantalum Niobium Alloy, Ta-40Nb): Comprising 60% tantalum and 40% niobium, this alloy is highly resistant to corrosion and has superior mechanical properties at high temperatures, making it ideal for use in nuclear reactors and other high-stress environments.

Production Standards

The production of tantalum sheets, foils, and plates is regulated by several standards to ensure quality and consistency:

Quality Assurance and Compliance

MetalsTek conducts a series of quality checks to comply with these standards, including mechanical testing, chemical analysis, and dimensional inspections. These checks help identify any deviations from the set standards and ensure that the final product performs as expected in its specific application.

You might be wondering, is tantalum more expensive than gold? The answer is no! Tantalum is not as expensive as gold, but it is still quite pricey. To get a better understanding of why, let’s dive deeper into the topic.

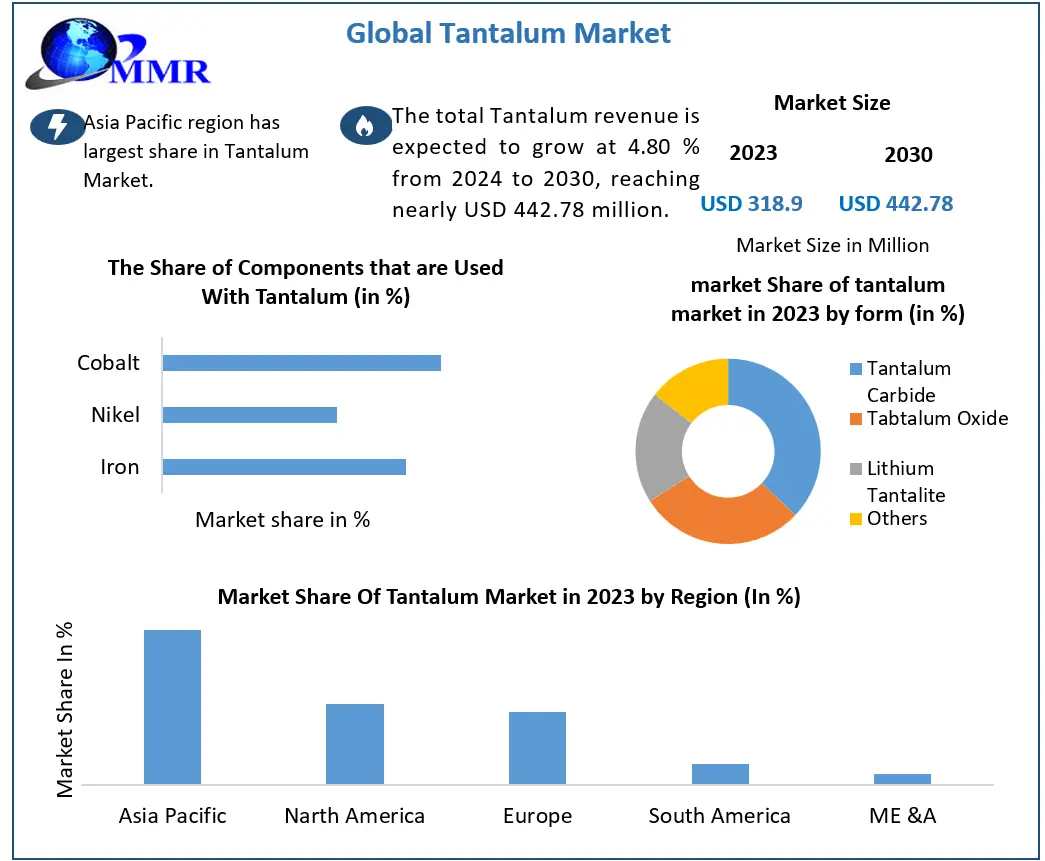

Supply Chain and Source Factors

Demand Dynamics

*Quoted from: MMR

Pricing Considerations

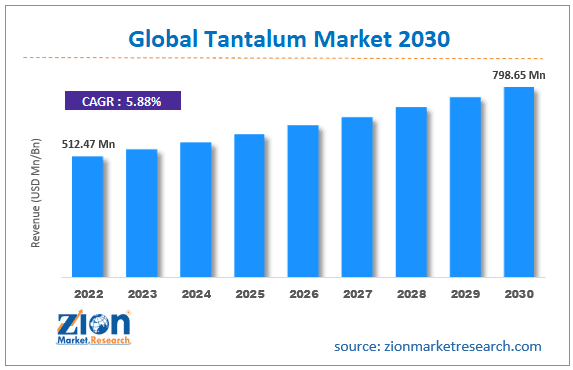

Market Trends and Future Outlook

*Quoted from: zionmarketresearch.com

Tantalum sheets, foils, and plates are crucial for technological advancements in various industries, such as electronics and aerospace. By comprehending their distinctive characteristics and uses, businesses can utilize this metal to improve the performance and dependability of their products.

We encourage professionals in the industry to explore how tantalum can be incorporated into their projects or to reach out to us at MetalsTek for comprehensive product specifications and professional guidance.

Tantalum sheets, foils, and plates are crucial for technological advancements in various industries, such as electronics and aerospace. By comprehending their distinctive characteristics and uses, businesses can utilize this metal to improve the performance and dependability of their products.

We encourage professionals in the industry to explore how tantalum can be incorporated into their projects or to reach out to us at MetalsTek for comprehensive product specifications and professional guidance.