Menu

MetalsTek Engineering is a reliable partner for industries seeking advanced metallurgy solutions, particularly in titanium alloys.

Material: Titanium-Zirconium-Molybdenum

Composition: Molybdenum, 0.50% Titanium, 0.08% Zirconium, and 0.02% Carbon

Density: 9.8 – 10.2 g/cc

Melting Point: 2,623°C (4,793°F)

Shape: Sheet, Plate, Rod, and More

Material: C.P. Titanium, Ti-6Al-4V

Density: 4.51 g/cc

Shape: Customize per Data/Drawing

Size: Customized

Material: Ti-Nb Alloy, Nb: 42% to 47%

Standard: ASTM B265, UNS R58450

Shape: Rod, Plate, or Customize per Data/Drawing

Size: Customized

Other: TiNb, NbTi, Titanium Grade 36, 55Ti-45Nb, Ti-45Nb

Material: Zirconium Titanium, Ti-10%/30%/50%

Shape: Customize per Data/Drawing

Size: Customized

Material: Platinized Titanium Anode

Coating: Platinum (<10μm)

Voltage: ≤12V

Shape: Rod, Wire, Mesh, Customize per Data/Drawing

Size: Customized

Material: Ti-5Al-5Mo-5V-3Cr

Density: 4.62 g/cc

Shape: Customized per Data/Drawing

Size: Tailored Size

Main Application: Aircraft Skeleton and Structural Parts, Landing Gear, Medical Use

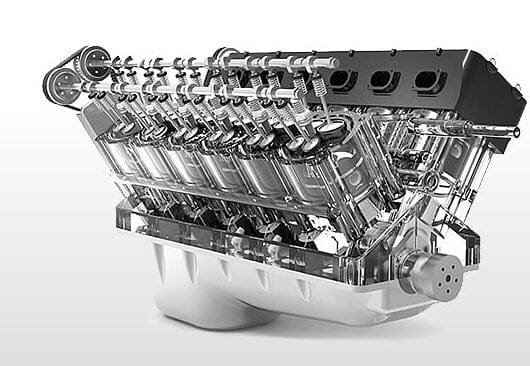

Material: Ti-6Al-2Sn-4Zr-2Mo-Si

Density: 4.5 g/cc

Melting Point: 1,588-1,716 °C

Type: Customized per Data/Drawing

Main Application: Racing Engine Components, Airframe Structures, Rotor Blade, Jet Engine Compressors

Material: Ti-6Al-2Sn-4Zr-6Mo

Melting Point: 1,593-1,677 °C

Type: Customized per Data/Drawing

Applications: Aerospace, Medical, Chemical, Marine, Automotive, Sporting Equipment

Material: Ti-5Al-2Sn-2Zr-4Cr-4Mo, UNS R58650

Melting Point: 1,593-1,677 °C

Strength: 1,000 MPa Tensile, 1,140 MPa Yield

Type: Customized per Data/Drawing

Applications: Aero Engine, Fans Compressor, Fasteners, Hydraulic Pipes, etc.

Material: Titanium Copper – Gr 1, 2 Titanium & T1, T2, T3, T4 Cu

Titanium Aluminum – Gr 1/2/3/7/12/16, L/Ly/LF

Titanium Nickel – Gr 1/2/3/7/12/16, N2/N4/N6

Titanium Stainless Steel – Gr1/2/3/5/9/11/12, SUS304/410

Titanium Carbon Steel – Gr 1, SA516 Gr70

Other: Two- or Three-Layers Plate

Shape: Customize per Data/Drawing

Size: Customized

Material: Ferro Titanium FeTi, Ferro Titanium Silicon FeSiTi, Ferro Titanium Carbide, FeTiC,

Purity: 99.9%, or Customized

Particle Size: Large Range, Customized

| Grade | Bal. | Si | Fe | Cu | Mn | Cr | Ni | Ti | B | V | Zn | Pb | Sn | Mg | C | Other Single | Total Impurities |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AlTi3 | Al | 0.3 | 0.35 | / | / | / | / | 2.5~3.5 | / | / | / | / | / | / | / | 0.05 | 0.15 |

| AlTi4 | Al | 0.2 | 0.3 | / | / | / | / | 3.5~4.5 | / | / | 0.1 | / | / | / | / | 0.05 | 0.15 |

| AlTi5 | Al | 0.5 | 0.45 | 0.15 | 0.35 | 0.1 | 0.1 | 4.5~5.5 | / | 0.25 | 0.15 | 0.1 | 0.1 | 0.5 | / | 0.05 | 0.15 |

| AlTi6 | Al | 0.3 | 0.35 | / | / | / | / | 5.5~6.5 | 0.004 | 0.3 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi10 | Al | 0.3 | 0.35 | / | / | / | 0.05 | 9.0~11.0 | 0.004 | 0.5 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi6A | Al | 0.2 | 0.2 | / | / | / | / | 5.5~6.5 | 0.004 | 0.2 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi10A | Al | 0.2 | 0.2 | / | / | / | 0.05 | 9.0~11.0 | 0.004 | 0.2 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi12 | Al | 0.3 | 0.3 | / | / | 0.1 | 0.1 | 11.0~13.0 | / | 0.5 | / | / | 0.1 | / | / | 0.1 | 0.15 |

| AlTi15 | Al | 0.3 | 0.3 | / | / | 0.15 | 0.15 | 14.0~16.0 | / | 0.5 | / | / | 0.15 | / | / | 0.1 | 0.15 |

| AlTi3B1 | Al | 0.2 | 0.3 | / | / | / | / | 2.8~3.4 | 0.7~1.1 | / | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B0.2 | Al | 0.3 | 0.35 | / | / | / | / | 4.5~5.5 | 0.15~0.25 | 0.25 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B0.2A | Al | 0.15 | 0.2 | / | / | / | / | 4.5~5.5 | 0.15~0.25 | 0.2 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B0.2B | Al | 0.3 | 0.4 | / | / | / | / | 4.5~5.5 | 0.1~0.5 | 0.2 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B0.6A | Al | 0.2 | 0.3 | / | / | / | / | 4.5~5.5 | 0.5~0.7 | / | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B0.6 | Al | 0.2 | 0.3 | / | / | / | / | 4.5~5.5 | 0.5~0.7 | 0.2 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B1 | Al | 0.2 | 0.3 | / | / | / | / | 4.5~5.5 | 0.8~1.2 | 0.2 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B1A | Al | 0.15 | 0.2 | / | / | / | / | 4.8~5.2 | 0.9~1.1 | 0.05 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B1B | Al | 0.2 | 0.25 | / | / | / | / | 4.5~5.5 | 0.8~1.2 | 0.1 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi5B1C | Al | 0.2 | 0.3 | / | / | / | / | 4.5~5.5 | 0.4~1.2 | 0.2 | / | / | / | / | / | 0.03 | 0.1 |

| AlTi3C0.15A | Al | 0.2 | 0.2 | / | / | / | / | 2.6~3.4 | 0.004 | 0.05 | / | / | / | / | 0.08~0.22 | 0.03 | 0.1 |

| AlTi3C0.15 | Al | 0.3 | 0.15 | / | / | / | / | 2.6~3.4 | 0.004 | 0.3 | / | / | / | / | 0.08~0.22 | 0.03 | 0.1 |

| AlTi3C0.3 | Al | 0.2 | 0.2 | / | / | / | / | 2.6~3.4 | 0.004 | 0.05 | / | / | / | / | 0.25~0.35 | 0.03 | 0.1 |

| Other Products | AlMn, AlTi, AlNi, AlV, AlSr, AlZr, AlCa, AlLi, AlFe, AlCu, AlCr, AlB, AlRe, AlBe, AlBi, AlCo, AlMo, AlW, AlMg, AlZn, AlSn, AlCe, AlY, AlLa, AlPr, AlNd, AlYb, AlSc, etc. | ||||||||||||||||

Type: WC/TiC/TaC, AlTiB, AlTiC, LATP, NiTi, Ti-Cr-V, Ti-33Al-5Nb-3Cr, Ti-10V-2Fe-3Al, Ti-13V-11Cr-3Al, Ti-15V-3Cr-3Sn-3Al, Ti-3Al-2.5V, Nb42Ti58, Ti-6Al-7Nb, Ti-30Al-10Nb, Ti-NbC, FeTi30-A/B, FeTi40-A/B, FeTi70-A/B/C, Ti-5Al-2Sn-4Cr-4Mo, TiNbZr, TiAl, Ti45Al8Nb, TiMo, TiAlMo, etc.

Shape: Customize per Data/Drawing

Size: Customized

Titanium alloys are composed of a mixture of titanium and other chemical elements. These alloys are recognized for their high tensile strength, toughness, lightweight, exceptional corrosion resistance, and ability to withstand extreme temperatures. Owing to these extraordinary properties, they are extensively used in aerospace, military applications, bicycles, spacecraft, medical devices, and jewelry. Usually, titanium alloys contain small amounts of aluminum, molybdenum, vanadium, niobium, tantalum, zirconium, manganese, iron, chromium, cobalt, nickel, and copper, which contribute to their unique characteristics. There are different types of titanium alloys, such as Ti6Al7Nb, Ti5Al-25Sn, Ti6AL4V (Gr.5), Ti6AL-4V ELI (Gr.23), Ti3Al2.5V (Gr.9), Beta Alloys (Ti15V3Al3Sn3Cr), Ti6242, and more, each having distinct properties and being used in specific industries and applications. These titanium alloys have various applications across various industries due to their exceptional strength, corrosion resistance, and other desirable properties.

Titanium Alloys find extensive applications across various industries due to their exceptional combination of properties, including high strength-to-weight ratio, corrosion resistance, and biocompatibility. Here are some critical applications of Titanium Alloys:

These applications showcase the versatility and significance of Titanium Alloys across a wide range of industries, contributing to advancements in technology, healthcare, transportation, and more.