Menu

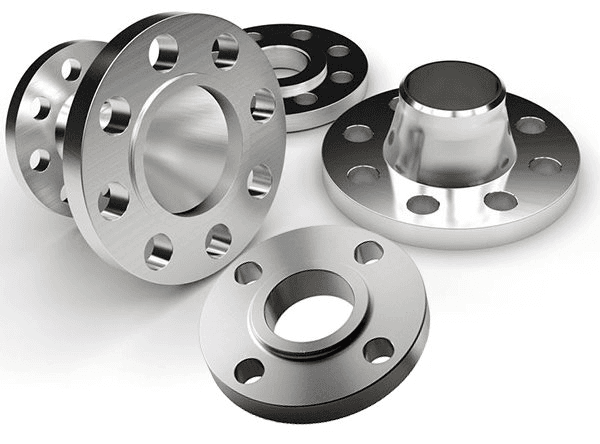

MetalsTek Engineering offers a comprehensive selection of titanium pipe fittings and flanges to meet the demands of various industrial applications. We provide reliable titanium pipe fittings and flanges with precision and excellence, whether for aerospace, chemical processing, marine, or other industries.

Material: Titanium and Titanium Alloy

Grade: Gr.1~Gr.12, Gr.23 / C.P. Ti, Ti-6Al-4V, Ti-6Al-4V ELI, etc.

Standard: DIN, ASME, JIS, HG, etc.

Size Range: DN10~DN2,000, Can be Customized

Surface: Mirror Polish Available

Pressure: PN6~PN150, 2,000~9,000 LBS

Additional components such as line spades, spacers, paddle blinds, paddle spacers, orifice plates, pipe plates, bleed rings, and spectacle blinds can be used in conjunction with these flange types as needed.

Material: Titanium and Titanium Alloy

Grade: Gr.1~Gr.12, Gr.23 / C.P. Ti, Ti-6Al-4V, Ti-6Al-4V ELI, etc.

Standard: DIN, ASME B16.9, ASTM B363, etc.

Size Range: DN10~DN1,000, Can be Customized

Type: Elbow, Tee, Reducer, Return, Coupling, Cap, Pipe Plug, Pipe Nipples, Stub Ends, Bushing, etc.

Processing: Welded, Hot Rolled, Cold Rolled, Extruded, Forged, Can be Polished

Size Range: Diameter <1,000mm, Thick 0.5~50mm

Titanium pipe fittings and flanges are essential components used in various industries due to the unique properties of titanium, including excellent corrosion resistance, high strength, and low density. These fittings and flanges come in multiple sizes and specifications to meet the diverse needs of different applications. Joint titanium pipe fittings and flanges include elbows, tees, caps, reducers, stub ends, couplings, and other highly customized options. They find applications in aerospace, chemical processing, marine, medical, and architectural industries.

| Grade | N | C | H | Fe | O | Al | V | Ti |

|---|---|---|---|---|---|---|---|---|

| Gr. 1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | Balance |

| Gr. 2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | Balance |

| Gr. 3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | Balance |

| Gr. 4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | Balance |

| Gr. 5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5~6.75 | 3.5~4.5 | Balance |

| Gr. 7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | Balance |

| Gr. 9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5~3.5 | 2.0~3.0 | Balance |

| Gr.12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | Balance |

| Grade | Tensile Strength (min) | Yield Strength (min) | Elongation(%) | |||

|---|---|---|---|---|---|---|

| ksi | MPa | ksi | MPa | |||

| Gr. 1 | UNSR50250 | 35 | 240 | 20 | 138 | 24 |

| Gr. 2 | UNSR50400 | 50 | 345 | 40 | 275 | 20 |

| Gr. 3 | UNSR50550 | 65 | 450 | 55 | 380 | 18 |

| Gr. 4 | UNSR50700 | 80 | 550 | 70 | 483 | 15 |

| Gr. 5 | UNSR56400 | 130 | 895 | 120 | 828 | 10 |

| Gr. 7 | UNSR52400 | 50 | 345 | 40 | 275 | 20 |

| Gr. 9 | UNSR56320 | 90 | 620 | 70 | 438 | 15 |

| Gr. 12 | UNSR53400 | 70 | 438 | 50 | 345 | 18 |

Titanium Flanges and Pipe Fittings are used in various applications due to their exceptional properties such as high strength, lightweight, and corrosion resistance.

Titanium Flanges are essential in various industries, including aerospace, chemical processing, and marine applications. They connect pipes, valves, and other machinery, contributing to the safety, efficiency, and longevity of multiple systems.

Specific flanges, like the lap joint flange, are used in piping systems that require frequent dismantling for inspection and cleaning.

Titanium pipe fittings are utilized in aircraft hydraulic systems, chemical processing plants, offshore drilling rig components, maritime and subsea equipment, and medical implants, among other applications.

They are also used in power generation plants for transporting water and steam at high temperatures.

In the aerospace industry, titanium pipes are suitable for airframe and engine components due to their resistance to fatigue and cracking and their ability to operate at high temperatures.

In the oil and gas industry, titanium pipe fittings are advantageous due to their high strength, low density, and resistance to hostile environments with high pressure and temperatures.

In the chemical processing industry, titanium pipe fittings present a long-lasting solution due to their resilience to stress, crevice corrosion, and low likelihood of pitting.

In power generation, titanium pipes play a significant role in high-temperature water and steam systems.

Due to their lightweight, titanium flanges and fittings can also be used in weight-sensitive applications such as aeronautical, space, or portable systems.

In summary, titanium’s high strength, lightweight, and corrosion resistance make its flanges and pipe fittings ideal for various applications in various industries.

Our Titanium Flange and Pipe Fittings are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.