Menu

MetalsTek Engineering specializes in producing high-quality Titanium Foam, Electrode and Mesh, offering tailored solutions for diverse industrial needs. Whether for structural components, filtration systems, or biomedical devices, Titanium Foam and Mesh demonstrate advanced capabilities and the versatility of titanium materials.

Material: Titanium and Titanium Alloys

Shape: Sheet, Plate, Strip, Round Square, or Customized Shapes

Size: Thick 0.3~10mm, Tailored Sizes

Foam Filter Size: Customized

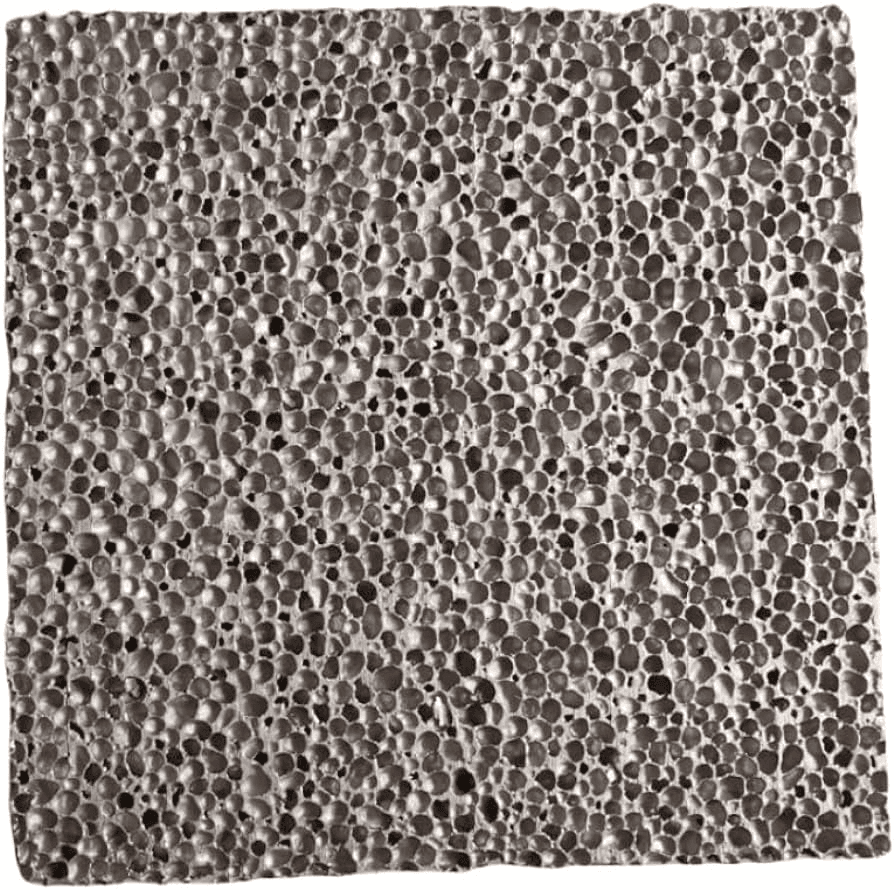

Titanium Foam Description

Ultra-light quality: It has the largest specific surface area, the specific gravity is 0.2~0.3, which is 1/4 of water, 1/3 of wood, 1/10 of metal aluminum, 1/30 of iron, and ultra-light quality.

Sound absorption: The porous structure has a wide frequency of sound absorption.

Electron wave shielding: Shields electron waves of around 90 dB through a relatively thin thickness.

Processability: Can be cut, bent, and simply pasted.

Fire resistance: It maintains a stable shape and is difficult to burn at high temperatures and is resistant to high temperatures.

Recycling: Metal waste materials can be recycled 100%.

Thermal conductivity: Porous materials have strong thermal conductivity.

Breathable: a homogeneous three-dimensional network structure with filtering effect and the flow stability of gas and fluid is super strong.

Sound insulation: Through additional processing, a high noise interception can be obtained, and the sound insulation effect is good.

Titanium Foam Applications

With its exceptional properties, titanium foam finds extensive applications across various industries, making it a material with promising development prospects. Some typical uses include:

The versatility of titanium foam makes it a valuable material in addressing diverse filtration needs across different sectors.

Material: C.P. Titanium

Density: ~4.51 g/cc

Surface: Pickled

Standard: ASTM B265

Size: 0.3-2.0mm * 1,000mm * Tailored Length

Other Materials: Tungsten, Molybdenum, Nickel, Copper, Aluminum, Silver, Stainless Steel

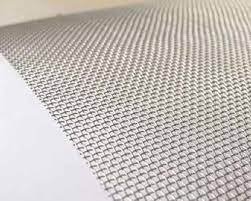

Material: C.P. Titanium

Density: ~4.51 g/cc

Surface: Pickled

Size: 2D/3D 0.6*42~150*42~150mm

Feature: Easily Molded and Cut, High Strength, Compatible with Cr, MRI and DSA

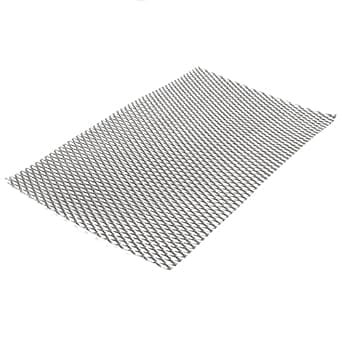

Material: Titanium and C.P. Titanium

Density: ~4.51 g/cc

Surface: Pickled, Black, Polished

Standard: ASTM B863, ASTM F136-Medical

Size: Dia.0.05~10mm Ti Wire, 1~150 Mesh Size

Material: Titanium, Ti

Purity: Ti>99.9%

Density: ~4.51 g/cc

Fiber Diameter: 20-160 μm

Length: 1mm, 2mm, 3mm, 5mm, up to 150mm

Material: Titanium, Ti

Purity: Ti>99.9%

Density: ~4.51 g/cc

Porosity: 75%~85% (Thick 0.3~0.68mm)

Titanium Fiber Felt is produced through a unique laying process and an ultra-high temperature vacuum sintering procedure. In comparison to titanium powder sintered plates, Ti fiber felt exhibits outstanding features, including an intricate three-dimensional network, porous structure, high porosity, large surface area, uniform pore size distribution, exceptional strength, corrosion resistance, and malleability for rolling and processing. This versatile material finds extensive applications in military, aerospace, civil, and medical industries globally.

Titanium fiber felts play a crucial role in electrolyze stacks, serving as the flow field or diffuser material, particularly on the oxygen (anode) side.

| Product Name | Sintered Tube Filter |

|---|---|

| Size of Seamless Tube (Outer Diameter *Wall Thickness*Length, mm) | 20×2×(30-300) |

| 30×2×(50-500) | |

| 35×2×(50-1000) | |

| 40×2×(50-1000) | |

| 50×2.5×(50-1500) | |

| 60×2.5×(100-2000) | |

| 65×2.5×(100-2000) | |

| 75×3×(100-1800) | |

| 80×3×Length(customizable) | |

| 90×3.5×Length(customizable), etc | |

| Type of Interface | Threaded Interface: |

| G1/2、G3/4、M20、M30、M36、M42, etc | |

| Filter Element Enterface: | |

| 215, 220, 222, 226, Pressure Filter, etc | |

| Flange Interface |

| Model | Size of blocked particle under 98% filtration efficiency | Size of blocked particle under 99.9% filtration efficiency | Permeability | Relative gas permeability | Mpa |

|---|---|---|---|---|---|

| (μm) | (μm) | (10-12m2) | [m3/(h·kPa·m2)] | ||

| ADSG-3 | 3 | 5 | 0.18 | ≥18 | 3 |

| ADSG-10 | 10 | 15 | 0.9 | ≥90 | 3 |

| ADSG-20 | 25 | 35 | 4 | ≥400 | 3 |

| ADSG-60 | 50 | 80 | 7.5 | ≥750 | 2.5 |

Note: The permeability in the above examples corresponds to filters with wall thickness of 2mm.

Applications

Gas and liquid filtration

Filtering and recycle of solid catalyst

Filtration of Petrochemical products

Purification of gas and smog

Purification of dust and exhaust gas

Aeration in water treatment

Titanium Foam and Mesh are lightweight materials with a high porosity level, typically 75-95%. They are stiff and exhibit high specific strength, excellent corrosion resistance, and biocompatibility, making them ideal for various applications. In the aerospace industry, Titanium Foam and Mesh are used for their high strength-to-weight ratio, energy absorption, and corrosion resistance. In biomedical applications, their porous form makes them suitable for orthopedic load-bearing and dental implants. Titanium Foam and Mesh also serve as battery and supercapacitor research substrates, offering better electrolyte corrosion resistance than copper and nickel foam. The material finds applications in the pharmaceutical, water treatment, food, chemical, biological engineering, petrochemical, metallurgical, and gas purification industries. The compressive strength of Titanium Foam and Mesh ranges from 4-6 MPa, with a filtration efficiency of 98% and a porosity of 30-50%. The material is available in various dimensions and thicknesses, making it a versatile solution for various industrial and research applications.

A titanium filter is a filtration device crafted from titanium or titanium alloys, renowned for its exceptional corrosion resistance, high strength, and lightweight properties. These filters are designed to separate particles or impurities from liquids or gases in various industrial processes. Titanium filters find applications across diverse industries, including:

Using titanium in filter construction ensures durability, resistance to harsh environments, and compatibility with a wide range of substances. Titanium filters are valued for their longevity and efficiency in maintaining the quality of liquids and gases in critical industrial processes.

Our Titanium Foam Mesh Fiber Filter are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.