Menu

MetalsTek Engineering offers high-quality Titanium Powder that sets the benchmark in deposition materials. Our finely divided particles are ideal for cutting-edge technologies, including additive manufacturing and powder metallurgy. As a leading manufacturer and supplier, we take pride in delivering exceptional quality and purity that meets the stringent demands of diverse industries.

Purity: Ti≥99.5%, TA1, TA2, TA3

Shape: Spherical Powder

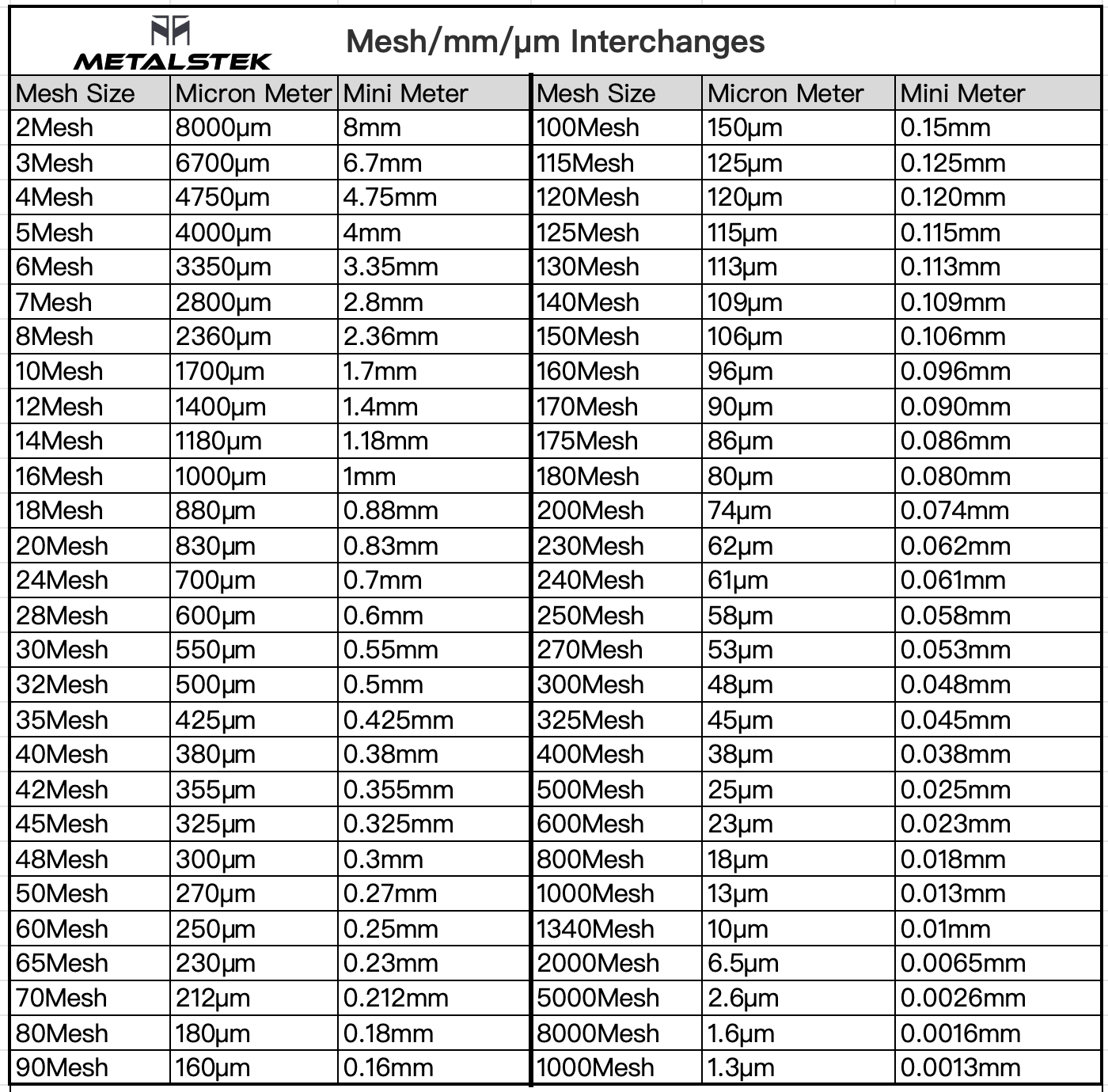

Particle Size: 0-15μm,15-53μm,45-105μm,75-150μm

Oxygen Content: 800~1,500 ppm

Main Application: 3D Printing (Additive Manufacturing)

| Grade | Ti | Fe | C | N | H | O | Other-Single | Other-Sum. |

|---|---|---|---|---|---|---|---|---|

| TA1 | Balance | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | 0.1 | 0.4 |

| TA2 | Balance | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA3 | Balance | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | 0.1 | 0.4 |

Purity: Ti≥99.5%

Particle Size: -75µm, 18-90µm, 53-180µm, 90-250µm

Process: HDH Process (hydride – dihydride)

Purity: Ti≥99.9%

Density: 4.507 g/cc

Thermal: 1,668℃ M.P., 3,260℃ B.P

Shape: Nearly Spherical

Particle Size: 325 Mesh

Purity: Ti≥99.9%

Specific Surface Area: 15 m2/g

Bulk Density: 0.54 g/cc

Thermal: 1,668℃ M.P., 3,260℃ B.P

Shape: Nearly Spherical

Particle Size: 80nm

Composition: Titanium Based, Cu, Sn

Impurities: Fe≤0.20%, C≤0.08%, O≤1,300ppm, N≤300ppm

Shape: Spherical

Particle Size: 15~53µm, 45~105µm

Applications: Aerospace Parts, Aero-Engine Blades, Medical Equipment

Composition: Titanium Based, Fe, C, O, N Added

Grade: GR. 1~4

Particle Size: 0~25µm, 15~45µm, 15~53µm, 20~63µm, 45~106µm, 45~150µm, or Customized

| Grade | Ti | Fe | C | N | H | O | Other-Single | Other-Sum. |

|---|---|---|---|---|---|---|---|---|

| TA1 | Balance | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | 0.1 | 0.4 |

| TA2 | Balance | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA3 | Balance | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | 0.1 | 0.4 |

| Grade | Titanium | Fe | C | O | H | N |

|---|---|---|---|---|---|---|

| Grade 1 | Bal. | 0.20% | 0.08% | 0.18% | 0.02% | 0.03% |

| Grade 2 | Bal. | 0.30% | 0.08% | 0.25% | 0.02% | 0.03% |

| Grade 3 | Bal. | 0.30% | 0.08% | 0.35% | 0.02% | 0.05% |

| Grade 4 | Bal. | 0.50% | 0.08% | 0.40% | 0.02% | 0.05% |

Titanium Powder is finely divided particles of titanium metal. Titanium Metal is a versatile material widely used in various industries due to its unique properties. It is a lustrous and silvery-white transition metal with the atomic number 22 and atomic weight 47.867. Titanium has a melting point of 1,660°C, a density of 4.5 g/cc, and a vapor pressure of 10-4 Torr at 1,453°C. It is known for its excellent corrosion resistance, biocompatibility, and strength-to-weight ratio, making it ideal for various applications.

Titanium Powder is a versatile material with various applications across various industries. It is used in foundries, die castors, pyrotechnics, powder metallurgy, steel production, and thermal spray applications. Titanium Powder is also employed in producing titanium sputtering targets, essential for thin-film deposition processes.

| Type | Properties | Metric | English |

|---|---|---|---|

| Descriptive Properties | Titanium, Ti | 100% | 100% |

| CAS Number | 7440-32-6 | 7440-32-6 | |

| Physical | Density | 4.50 g/cc | 0.163 lb/in³ |

| Mechanical Properties | Hardness, Brinell | 70 | 70 |

| Hardness, Vickers | 60 | 60 | |

| Tensile Strength, Ultimate | 220 MPa | 31900 psi | |

| Tensile Strength, Yield | 140 MPa | 20300 psi | |

| Elongation at Break | 54% | 54% | |

| Modulus of Elasticity | 116 GPa | 16800 ksi | |

| Poissons Ratio | 0.34 | 0.34 | |

| Electrical Properties | Electrical Resistivity | 0.0000554 ohm-cm | 0.0000554 ohm-cm |

| Magnetic Susceptibility | 1.25e-6 | 1.25e-6 | |

| Critical Magnetic Field Strength, Oersted | 56 | 56 | |

| Critical Superconducting Temperature | 0.360 - 0.440 K | 0.360 - 0.440 K | |

| Thermal Properties | Heat of Fusion | 435.4 J/g | 187.3 BTU/lb |

| CTE, linear | 8.90 µm/m-°C | 4.94 µin/in-°F | |

| CTE, linear | @Temp. 20.0 - 100 °C | @Temp. 68.0 - 212 °F | |

| CTE, linear | 10.1 µm/m-°C | 5.61 µin/in-°F | |

| Specific Heat Capacity | @Temperature 1000 °C | @Temperature 1830 °F | |

| Specific Heat Capacity | 0.528 J/g-°C | 0.126 BTU/lb-°F | |

| Thermal Conductivity | 17.0 W/m-K | 118 BTU-in/hr-ft²-°F | |

| Melting Point | 1650 - 1670 °C | 3000 - 3040 °F | |

| Optical Properties | Emissivity (0-1) | 0.63 | 0.63 |

Some typical applications of Titanium Powder include:

MetalsTek Engineering ensures the quality and purity of our Titanium Powder, catering to the specific needs of industries relying on titanium-related materials. Our commitment lies in providing reliable and high-performance products for various applications.

Our Titanium Powders are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.