Menu

A thermocouple sheath is a protective tube that encases a thermocouple, shielding it from harsh environments, chemical reactions, and mechanical damage. Sheaths made from tungsten and molybdenum are engineered for exceptional heat resistance, making them ideal for use in extreme temperature settings such as furnaces, vacuum systems, and molten metal applications.

At MetalsTek, we specialize in providing high-quality thermocouple sheaths designed for reliability, accuracy, and long-lasting performance. Learn how these advanced materials can elevate your temperature measurement applications.

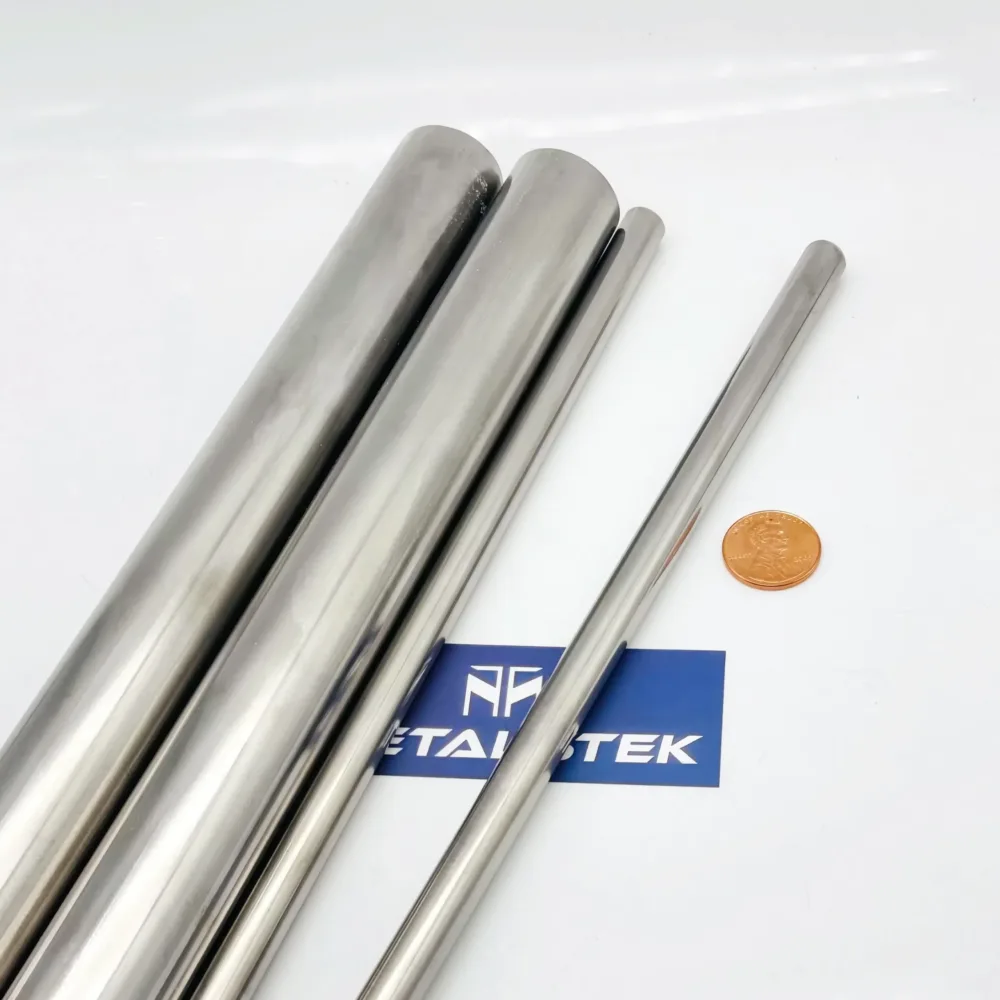

Material: Tungsten (W)

Purity: 99% ~ 99.99%

Shape: Tube with One Endcap

Size Range: Diameter 3-500mm; Thickness 0.4-30mm; Length <2,000mm

Density: >18.5 g/cc

Vickers Hardness: >450 HV

Surface: Machined, Cleaned, or Finished

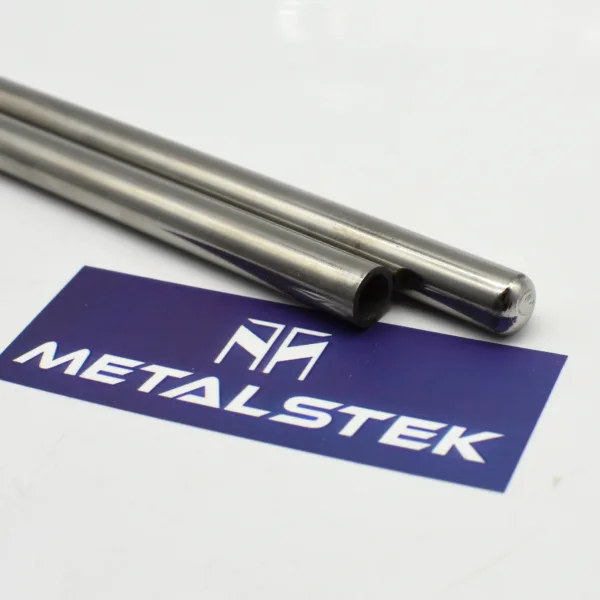

Material: Molybdenum (Mo), Mo-1, Mo-2

Purity: 99.95% Min

Standard: ASTM B386

Size Range: Diameter 0.5~600mm, Wall Thick 0.1~30mm, Length 5~6,000mm

Surface: Polished(Ra<3.2), Chemical Cleaned

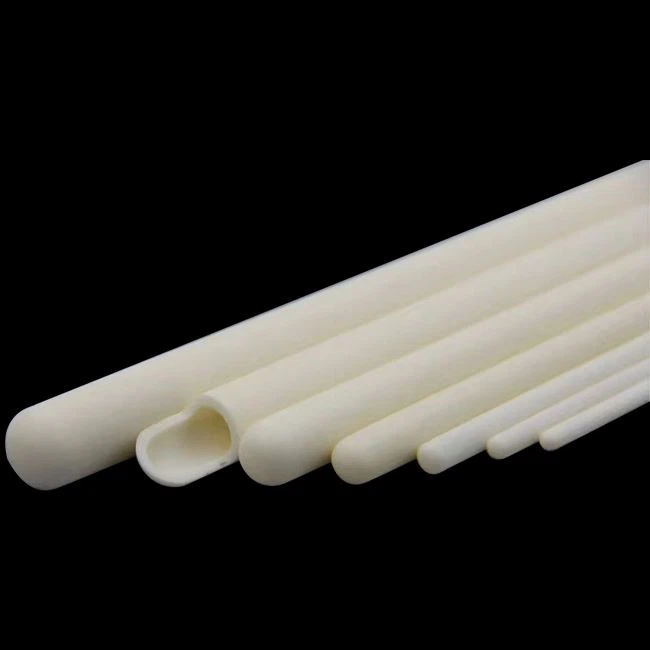

Material: Aluminia, Zironia, or Customized

Shape: Tube with One Endcap, Custom Shapes

Purity: 95%, 99%, 99.9%, can be customized

Sizes: Tailored Sizes

Material: Stainless Steel

Alloy Type: Inconel, Duplex, Monel, Incoloy, HastelloyAus Steel, SS Steel, or Customized

Product Form: Tube with one end capped, or customized shape

Surface: Finished

| Property | Tungsten | Molybdenum |

|---|---|---|

| Melting Point | 3422°C (6192°F) | 2623°C (4753°F) |

| Corrosion Resistance | Excellent in inert/reducing atmospheres | Good in vacuum or inert atmospheres |

| Durability | High wear resistance | Moderate wear resistance |

| Best Applications | Ultra-high temperatures, aerospace | High-temperature industrial furnaces |

If your process involves temperatures above 3000°C or extreme durability, choose tungsten. For cost-effectiveness in slightly lower temperatures, molybdenum is ideal.

At MetalsTek, we understand that standard solutions may not fit every application. That’s why we offer:

We use only the highest purity tungsten and molybdenum to ensure consistent performance and durability.

Our team specializes in crafting solutions tailored to even the most demanding applications.

From design to delivery, we prioritize your timeline without compromising on quality.

Serving industries across North America, Europe, and beyond.

Ready to enhance your temperature measurement systems with high-quality tungsten and molybdenum thermocouple sheaths? Contact MetalsTek today for expert advice, custom solutions, and a quote tailored to your needs.

Request a Quote Now or email us at sales@metalstek.com