Menu

Tungsten Carbide products include Tungsten Carbide (WC) Powder, Spherical Cast Tungsten Carbide Powder, Macro Tungsten Carbide Powder, Tungsten Carbide Rod, Plate, Tungsten Carbide Die, Drill, Cutter and Tips, Tungsten Carbide Alloys.

MetalsTek Engineering is a professional supplier of Tungsten Carbides. We offer various Tungsten Carbide products at high quality and competitive prices.

Material: Tungsten Carbide (WC)

Purity: WC-99.9% Min

Hardness: 93-93.7 HRA

Density: 16.5 g/cc

Particle: 0.4-60μm, Can be Customized

Morphology: Hexagonal

Melting Point: 2,870℃ / 5,198F

CAS #: 12070-12-1

Other: Spherical and Cast Tungsten Carbide Powder Available

Tungsten carbide powder (WC) serves as the main ingredient in the production of cemented carbide. It appears as a black six-square crystal with a metallic luster and boasts a hardness akin to a diamond. Notably, it is an excellent conductor of both electricity and heat. With a melting point of 2,870°C and a boiling point of 6,000°C, tungsten carbide finds extensive industrial use in metal drilling, turning, and milling, primarily through carbide tools.

| Classified | Grade | Particle Size (BET/μm) | Carbon Ratio (%) | Total Carbon (%) | Main Impurity | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ultra-Fine Powder | WC02 | BET: ≥2.5 | ≤0.15 | 6.20±0.05 | O≤0.50 | |||||||

| WC05 | BET: 1.9-2.5 | ≤0.12 | 6.20±0.05 | O≤0.35 | ||||||||

| WC07 | 0.60-0.80 | ≤0.10 | 6.18±0.05 | O≤0.25 | ||||||||

| Fine Powder | WC10 | 0.90-1.50 | ≤0.06 | 6.15±0.05 | O≤0.15 | |||||||

| WC15 | 1.50-2.00 | ≤0.06 | 6.13±0.05 | O≤0.12 | ||||||||

| WC20 | 2.00-2.50 | ≤0.05 | 6.13±0.05 | O≤0.10 | ||||||||

| Medium-Fine Powder | WC25 | 2.50-3.00 | ≤0.05 | 6.13±0.05 | O≤0.07 | |||||||

| WC30 | 3.00-4.00 | ≤0.05 | 6.13±0.05 | O≤0.05 | ||||||||

| WC40 | 4.00-5.00 | ≤0.05 | 6.13±0.05 | O≤0.04 | ||||||||

| WC50 | 5.00-6.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| WC60 | 6.00-8.00 | ≤0.05 | 6.13±0.05 | O≤0.04 | ||||||||

| Coarse Powder | WC80 | 8.00-10.00 | ≤0.05 | 6.13±0.05 | O≤0.04 | |||||||

| WC100 | 10.00-15.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| Extra-Coarse Powder | WC150 | 15.00-20.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | |||||||

| WC200 | 20.00-30.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| WC400 | 30.00-40.00 | ≤0.05 | 6.13±0.05 | O≤0.03 | ||||||||

| WC600 | 40.00-60.00 | ≤0.05 | 6.13±0.05 | O≤0.03 |

Material: Tungsten Carbide Alloy

Alloy Types: Tungsten Carbide Cobalt Powder (WC/Co), Tungsten Carbide Nickel Powder (WC/Ni), Tungsten Carbide Cobalt Chromium (WC/Co/Cr), Tungsten Carbide Nickel Chromium (WC/Ni/Cr)

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14-15.2 g/cc

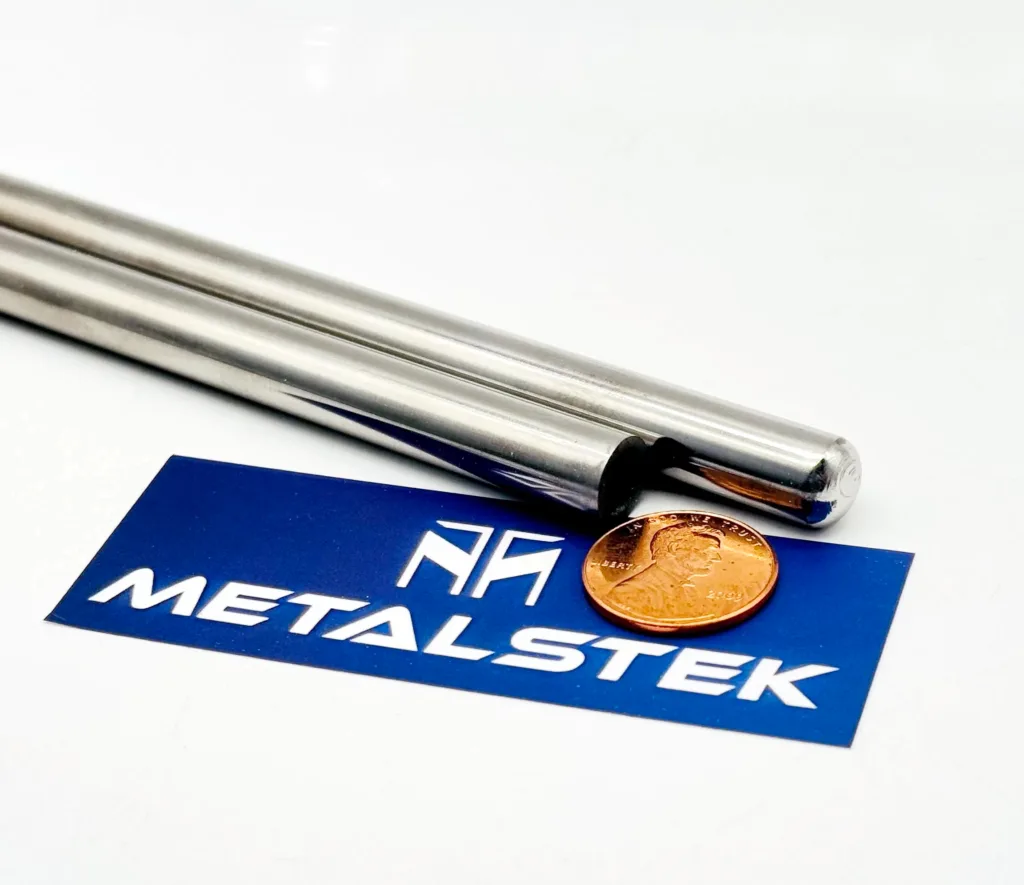

Surface: Grinding

Rod Type: PCB Rod / Blank Rod

Size Ranges: PCB Rod – Dia.3.25~7mm * Length 12~40mm

Blank Rod – Dia.1.0~42mm * Length 30~700mm

Other: Tungsten Carbide Rod with One or Two Holes Available

Cemented Tungsten Carbide Rod is a sintered metallurgical product of powder form. It is manufactured in vacuum or Hydrogen reduction furnaces with refractory Tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni), or Molybdenum (Mo) as the binder.

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14-15.2 g/cc

Surface: Grinding

Sizes: Customized Sizes

Other: Tungsten Carbide with Endcap(s)

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14-15.2 g/cc

Surface: Grinding

Size Ranges: Thickness 1~20mm, Width 2~40mm, Length 10~200mm

Other: Size Can be Customized

Cemented Tungsten Carbide Strip is a sintered metallurgical product of powder form. It is manufactured in vacuum or Hydrogen reduction furnaces with refractory Tungsten material (WC) micron powder as the main ingredient and Cobalt (Co), Nickel (Ni), or Molybdenum (Mo) as the binder.

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14-15.2 g/cc

Surface: Grinding

Drill Types: PCB Drill, Slot Drill, Step Drill

Size Ranges: PCB Drill – Dia.0.2~3.175mm * Depth 3.5~12.2mm

Slot Drill – Dia.0.4~3.0mm * Depth 5.0~8.7mm

Step Drill – Dia.3.2~6.5mm * Depth 12.5mm

A Tungsten Carbide Drill is composed of an equal ratio of tungsten and carbon atoms. Initially presenting as a fine gray powder, this compound can be shaped through a method known as sintering, enabling its application in industrial machinery, cutting tools, abrasives, armor-piercing bullets, and even jewelry. Renowned for its exceptional hardness, tungsten carbide drills find utility in demanding sectors such as mining, tunneling, and construction industries.

Material: Tungsten Carbide-Cobalt (WC-Co)

Purity: WC 85-94%

Density: 14.5-15.6 g/cc

Surface: Grinding

Size: Customized

Other: Can be Customized

Tungsten Carbide Cutters & Tips are well-suited for shaping, smoothing, or grinding challenging materials such as hardened steel, stainless steel, cast iron, nonferrous metals, fired ceramics, plastics, and hardwoods.

MetalsTek Engineering specializes in crafting personalized Tungsten Carbide Cutters, Saw Tips, Carbide Brazed Tips, and Mining Tips tailored to your specific requirements.

Material: Tungsten Carbide / Alloys

Product: As Requested

Remark: Tungsten Carbide can be used for various products; you can feel free to contact our salesperson to custom according to your applications. The products including Grinding Jars and Balls, Mortar and Pestle, Dies, etc.

Tungsten carbide often denoted as WC is a compound comprised of tungsten and carbon atoms. This chemical compound is renowned for its exceptional hardness and wear resistance. It is an ideal material for cutting tools, drilling bits, milling inserts, and other applications where resistance to abrasion and wear is critical.

The compound’s exceptional toughness and thermal stability further contribute to its widespread use. Its ability to withstand high temperatures without losing its hardness makes it suitable for applications in high-speed machining and other demanding environments.

Tungsten Carbide products include Tungsten Carbide (WC) Powder, Spherical Cast Tungsten Carbide Powder, Macro Tungsten Carbide Powder, Tungsten Carbide Rod, Plate, Tungsten Carbide Die, Drill, Cutter and Tips, Tungsten Carbide Alloys.

Tungsten Carbide is a remarkable material with diverse applications due to its hardness, durability, and thermal stability. Widely used in various industries, from cutting tools and abrasives to industrial machinery and mining applications, Tungsten Carbide has proven indispensable for tasks requiring precision, wear resistance, and resilience in harsh conditions. Its unique properties make it a key player in enhancing the performance and longevity of tools and components across a spectrum of industrial and technological domains. The continued exploration of Tungsten Carbide’s potential and evolving applications further solidifies its position as a critical material in modern engineering and manufacturing.

| Grade | Composition (WC + Binder) | Hardness (HRA) | Toughness | Wear Resistance | Applications |

|---|---|---|---|---|---|

| C1 / YG6 | 94% WC, 6% Co | 89~91.5 | Medium | Medium | Non-ferrous metals, wood, plastics cutting. |

| C2 / YG8X | 90% WC, 10% Co | 87~90 | Medium-High | Medium-High | Cast iron, non-ferrous metals, light cuts on steel. |

| C3 | 97% WC, 3% Co | 91 | Medium | High | Wear parts, non-ferrous machining. |

| C4 | 97.5% WC, 2.5% Co | 92 | Low | Very High | Abrasive cutting, wear-resistant tools. |

| C5 / YG15 | 85% WC, 15% Co | 84~88 | High | Medium | Medium machining of steel, tough alloys. |

| C6 / YG12 | 88% WC, 12% Co | 86 | High | Medium-High | Heavy machining, severe steel cutting conditions. |

| C7 | 96% WC, 4% Co | 91 | Medium | Very High | Abrasive wear environments, forming tools. |

| C8 | 98% WC, 2% Co | 93 | Low | Maximum | Cutting and forming tools, extreme wear resistance applications. |

| C9 | 93% WC, 7% Ni | 88 | Medium-High | High | Corrosion-resistant applications, marine environments. |

| C10 / YG8 | 92% WC, 8% Co | 87~89.5 | High | Medium-High | Balanced toughness and corrosion resistance for general use. |

| C11 | Ultra-fine WC, 10% Co | 92 | Medium-High | Very High | Precision tools, fine machining applications. |

| C12 | Nano-grain WC, 8% Co | 93 | Medium | Ultra-High | High-precision tools, advanced wear components. |

| C13 | 90% WC, 10% Co + TaC, TiC | 87 | High | High | Mining tools, drilling bits, and construction equipment. |

| WC-Co | 90-95% WC, 5-10% Co | 89-91 | High | High | Sealing rings, nozzles, wear components (oil & gas). |

| WC-Ni | 90-95% WC, 5-10% Ni | 87-89 | Medium-High | Medium | Corrosion-resistant tools, offshore drilling. |

| ISO P10 | WC with TiC and Co | 92 | Medium | High | Steel machining, fine cutting. |

| ISO P20 | WC with TaC, TiC, Co | 89 | Medium-High | Medium-High | Steel machining, general-purpose. |

| ISO K10 | WC with Co | 91 | Medium | High | Cast iron machining, wear-resistant tooling. |

Our Tungsten Carbide Products are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.

When it comes to strength, durability, and reliability, few materials can rival the power of tungsten carbide. This remarkable compound is widely used in various industries, from manufacturing and construction to jewelry and cutting tools. In this article, we delve deep into the world of tungsten carbide, unraveling its uses, cost, strength, and hardness.

Tungsten carbide is renowned for its exceptional hardness, often surpassing even the likes of titanium and steel. This outstanding quality makes it ideal for applications requiring resistance to wear and tear, such as drill bits, machining tools, and industrial machinery components. Additionally, tungsten carbide has found its way into the jewelry industry, creating elegant and durable wedding bands and fashion accessories.

While tungsten carbide boasts impressive properties, it’s important to understand its cost implications as well. We explore the factors that contribute to the pricing of this material, including the scarcity of tungsten and the intricacies of the manufacturing process.

Join us as we unlock the potential of tungsten carbide, shedding light on its versatile applications, its incredible strength, and its significance in various industries. Learn why this mighty material is garnering attention and becoming a staple in so many fields.

Tungsten carbide, often referred to as simply carbide, is a compound composed of tungsten and carbon atoms, at 50-50 ratio. This unique material is renowned for its exceptional hardness, ranking among the hardest substances known to man. Tungsten carbide is produced through a powder metallurgy process, where tungsten powder is mixed with carbon black and then heated to high temperatures. The resulting product is a fine powder that can be pressed and formed into various shapes using high-pressure techniques.

Tungsten carbide’s hardness is attributed to its strong covalent bonds between the tungsten and carbon atoms, creating a rigid crystal lattice structure. This hardness gives tungsten carbide excellent resistance to abrasion, making it an ideal choice for applications where wear and tear are significant factors. Additionally, tungsten carbide exhibits high compressive strength, allowing it to withstand heavy loads without deformation or failure.

The versatility of tungsten carbide extends beyond its hardness and strength. It also has excellent thermal conductivity, which enables it to dissipate heat efficiently, making it suitable for high-temperature applications. Furthermore, tungsten carbide is corrosion-resistant, maintaining its properties even in harsh environments.

Tungsten carbide possesses a range of properties that make it a highly sought-after material in various industries. In addition to its exceptional hardness and strength, tungsten carbide is known for its high melting point, exceeding 5,000 degrees Fahrenheit. This property allows tungsten carbide to withstand extreme temperatures without losing its structural integrity.

Another key property of tungsten carbide is its low coefficient of thermal expansion, meaning it expands and contracts minimally with temperature changes. This stability makes tungsten carbide suitable for applications requiring precise dimensions and tight tolerances. Additionally, tungsten carbide has a high modulus of elasticity, providing rigidity and stiffness to components made from this material.

Moreover, tungsten carbide exhibits good electrical conductivity, making it useful in electronic applications. Its ability to maintain electrical conductivity while offering exceptional hardness and wear resistance makes tungsten carbide a preferred choice for components in electronic devices and machinery.

Tungsten carbide is renowned for its exceptional hardness, ranking among the hardest materials known, second only to diamond. This remarkable hardness allows tungsten carbide tools and components to maintain sharp cutting edges and resist wear and abrasion far better than steel alternatives.

Tungsten carbide has one of the highest melting points of all materials, making it suitable for high-temperature applications such as arc-welding electrodes, heating elements, and incandescent light bulb filaments.

Tungsten carbide exhibits outstanding compressive strength, significantly higher than most metals and alloys. This property enables it to withstand extreme loads without deformation or deflection, making it ideal for applications involving high compressive forces.

Tungsten carbide possesses a remarkably high degree of rigidity and stiffness, surpassing that of steel by a considerable margin. This characteristic prevents excessive flexing or bending under load, ensuring dimensional stability and precision in demanding applications.

The wear resistance of tungsten carbide is truly exceptional, outperforming steel by a factor of up to 100 times in abrasive, erosive, or galling conditions. This property makes tungsten carbide an ideal choice for cutting tools, mining equipment, and other applications where wear is a critical concern.

Tungsten carbide retains its hardness and strength at elevated temperatures up to 1000°C (1832°F) in oxidizing atmospheres. This unique property allows its use in high-speed machining, hot working applications, and other high-temperature environments.

Tungsten carbide has a significantly higher density compared to steel, contributing to its high weight and inertia. This characteristic can be advantageous in certain applications where weight and momentum are desirable.In essence, the combination of extreme hardness, high melting point, superior compressive strength, exceptional rigidity, unparalleled wear resistance, high-temperature strength retention, and high density make tungsten carbide an indispensable material for a wide range of demanding industrial applications.

The versatility and superior properties of tungsten carbide have led to its widespread use across diverse industries. In the manufacturing sector, tungsten carbide is commonly employed in cutting tools, such as drills, end mills, and inserts, due to its exceptional hardness and wear resistance. These tools can withstand high-speed machining operations and maintain sharp cutting edges for extended periods.

Tungsten carbide is also utilized in the production of wear parts for machinery and equipment in industries like mining, agriculture, and construction. Components made from tungsten carbide, such as nozzles, valves, and seals, exhibit excellent resistance to abrasion and corrosion, prolonging the lifespan of machinery and reducing maintenance costs.

Moreover, the jewelry industry has embraced tungsten carbide for its durability and lustrous appearance. Tungsten carbide rings and accessories are popular choices for wedding bands and fashion jewelry due to their scratch-resistant properties and long-lasting shine. The unique blend of strength and elegance makes tungsten carbide jewelry a preferred option for those seeking stylish and durable accessories.

Tungsten carbide offers a multitude of advantages that set it apart from other materials in various applications. One of the key advantages of tungsten carbide is its exceptional hardness, surpassing that of traditional materials like steel and titanium. This hardness translates to superior wear resistance, making tungsten carbide ideal for cutting, drilling, and machining operations where tools are subjected to high stresses.

Another advantage of tungsten carbide is its longevity and durability. Components made from tungsten carbide can outlast those made from conventional materials, reducing the frequency of replacements and maintenance. This longevity not only saves time and money but also enhances operational efficiency by minimizing downtime due to tool wear.

Furthermore, tungsten carbide’s high thermal conductivity and resistance to thermal deformation make it suitable for high-temperature applications where other materials may fail. Its ability to maintain structural integrity under extreme heat conditions ensures reliable performance in challenging environments.

While tungsten carbide boasts impressive properties, it is not without its limitations and drawbacks. One of the primary disadvantages of tungsten carbide is its brittleness, especially in certain grades and compositions. This brittleness can lead to chipping or fracturing under impact or shock loads, limiting its use in applications requiring toughness and resilience.

Another limitation of tungsten carbide is its high cost compared to conventional materials like steel and aluminum. The manufacturing process of tungsten carbide involves specialized equipment and techniques, contributing to its elevated price point. Additionally, the scarcity of tungsten as a raw material can influence the overall cost of tungsten carbide products, making them less cost-effective for some applications.

Moreover, tungsten carbide’s hardness can pose challenges for machining and shaping processes, requiring specialized tools and expertise to work with this material effectively. The hardness of tungsten carbide can lead to increased tool wear during shaping operations, adding to production costs and complexity.

When comparing tungsten carbide to other materials, several key differences and advantages become apparent. In terms of hardness and wear resistance, tungsten carbide outperforms materials like steel, aluminum, and even titanium. This superior hardness makes tungsten carbide a preferred choice for applications where abrasion and wear are significant factors.

Additionally, tungsten carbide offers better thermal conductivity and stability at high temperatures compared to materials like ceramics and polymers. Its ability to maintain structural integrity under extreme heat conditions sets tungsten carbide apart in applications requiring thermal resistance and reliability.

However, tungsten carbide’s brittleness can be a disadvantage when compared to materials like steel and titanium, which exhibit greater toughness and ductility. The trade-off between hardness and toughness must be considered when selecting materials for specific applications, as tungsten carbide may not be suitable for impact or shock-loading environments.

The cost of tungsten carbide products is influenced by various factors, including the price of raw materials, manufacturing processes, and market demand. Tungsten, the primary raw material used in producing tungsten carbide, is a relatively scarce element, which can impact the overall cost of tungsten carbide products. Fluctuations in tungsten prices due to supply and demand dynamics can affect the pricing of tungsten carbide components.

Moreover, the manufacturing process of tungsten carbide involves intricate steps such as powder mixing, compaction, sintering, and finishing, which require specialized equipment and expertise. These manufacturing complexities contribute to the higher cost of tungsten carbide compared to traditional materials like steel and aluminum.

Despite its higher initial cost, tungsten carbide’s longevity and wear resistance can result in cost savings over time. Components made from tungsten carbide often outlast those made from other materials, reducing the frequency of replacements and maintenance, which can offset the initial investment in tungsten carbide products.

Proper maintenance and care are essential to ensure the longevity and performance of tungsten carbide products. While tungsten carbide is highly resistant to scratches and wear, it is not immune to damage from harsh chemicals or extreme conditions. To maintain the appearance and functionality of tungsten carbide jewelry or components, regular cleaning with mild soap and water is recommended.

Avoid exposing tungsten carbide products to abrasive materials or harsh cleaning agents that can scratch or dull the surface finish. Store tungsten carbide jewelry separately from other pieces to prevent scratching and damage. In industrial applications, follow recommended maintenance schedules to inspect and replace tungsten carbide components as needed to prevent downtime and ensure optimal performance.

Additionally, consider consulting with a professional jeweler or manufacturer for specialized care and maintenance instructions for tungsten carbide products. Proper storage, cleaning, and handling practices can extend the lifespan of tungsten carbide items and maintain their aesthetic appeal and functionality for years to come.

In conclusion, tungsten carbide stands out as a remarkable material with unparalleled hardness, strength, and durability. Its versatility and superior properties have made it a popular choice in various industries, from manufacturing and construction to jewelry and electronics. While tungsten carbide may have limitations such as brittleness and higher cost, its advantages in wear resistance, thermal conductivity, and longevity outweigh these drawbacks.

As technology advances and new applications for tungsten carbide emerge, its significance in modern manufacturing and engineering processes continues to grow. The unique combination of hardness, toughness, and thermal stability makes tungsten carbide a valuable asset in creating high-performance tools, components, and products. By understanding the properties, uses, costs, and maintenance considerations of tungsten carbide, industries can harness the power of this extraordinary material to achieve superior results and enhance operational efficiency.

Unveiling the power of tungsten carbide reveals a world of possibilities and innovations where strength and reliability converge to shape the future of multiple industries. Embracing the potential of tungsten carbide opens doors to new advancements and solutions that push the boundaries of what is achievable with modern materials. As we continue to explore and utilize the capabilities of tungsten carbide, its impact on technology, manufacturing, and everyday life will undoubtedly continue to expand and inspire further developments in the years to come.