Menu

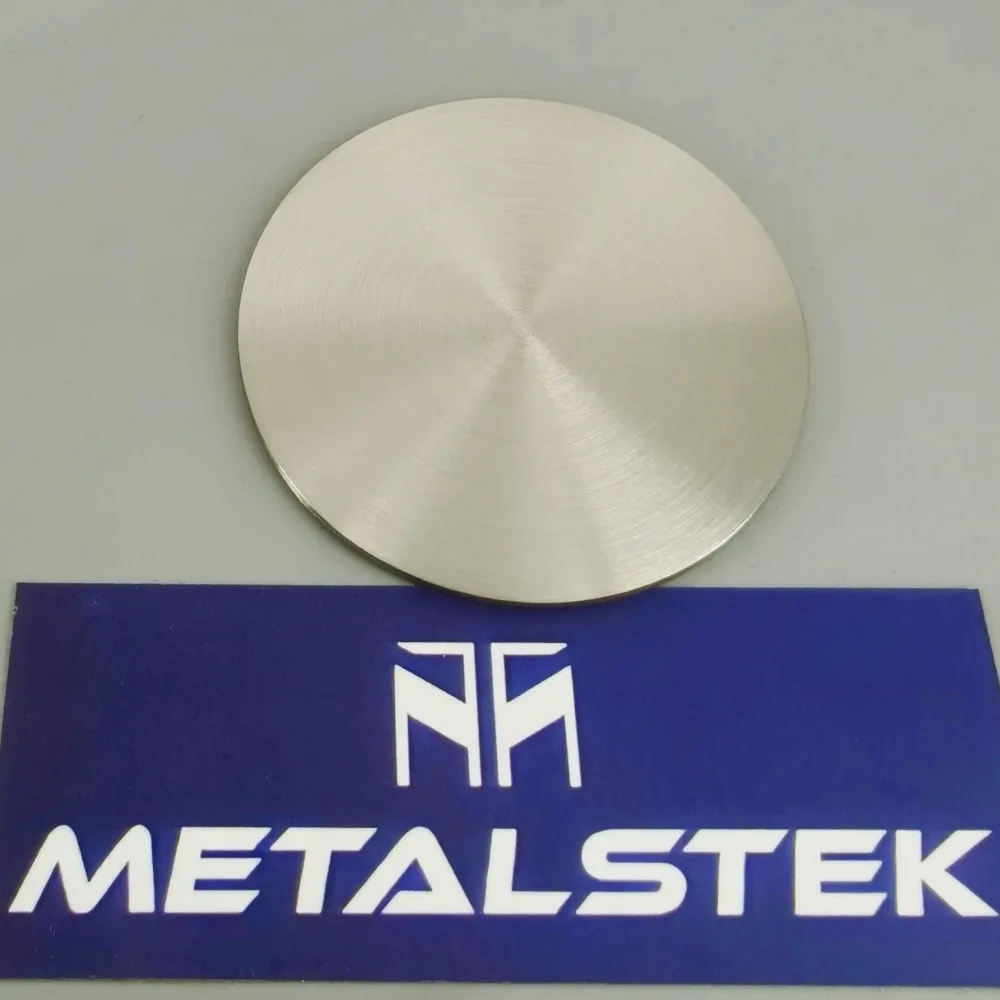

MetalsTek Engineering is a leading supplier of Tungsten Sputtering Targets. We offer competitive pricing and excellent lead times on all our materials, and we can supply custom materials per any specs/drawings you provide.

Sputtering targets back bonding service is available for these targets.

Material: Tungsten

Purity: W-99.95% Min

Standard Diameter: 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, 152.4mm/6”, and 203.2mm/8”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

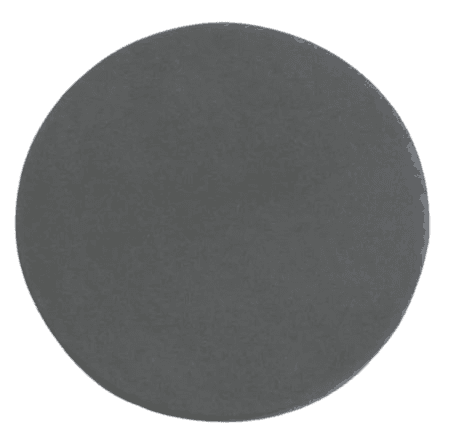

Material: Tungsten Carbide

Purity: WC-99.5% Min

Standard Diameter: 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, and 152.4mm/6”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

Material: Tungsten Disilicide

Purity: WSi2-99.5% Min

Standard Diameter: 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, and 127mm/5”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

Material: Tungsten Disulfide

Purity: WS2-99.9% Min

Standard Diameter: 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, 127mm/5”, 152.4mm/6”, and 203.2mm/8”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

Material: Tungsten Selenide (WSe2)

Purity: WSe2-99.9% Min

Standard Diameter: 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, 127mm/5”, 152.4mm/6”, and 203.2mm/8”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, Various Bondings

Material: Tungsten

Purity: W-99.9% Min

Standard Diameter: 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, 127mm/5”, 152.4mm/6”, 177.8mm/7”, and 203.2mm/8”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

Material: Tungsten Titanium

Purity: W/Ti-99.99% Min

Standard Diameter: Diameter 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, 152.4mm/6”, and 203.2mm/8”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

Material: Tungsten Nickel Boron

Purity: WNiB-99.99% Min

Standard Diameter: Diameter 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, 152.4mm/6”, and 203.2mm/8”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

Material: Tungsten Zirconium Boron

Purity: WNiB-99.99% Min

Standard Diameter: Diameter 25.4mm/1”, 50.8mm/2”, 76.2mm/3”, 101.6mm/4”, 152.4mm/6”, and 203.2mm/8”

Standard Thickness: 3.175mm/0.125”, 6.35mm/0.25”

Other: Customized shape and sizes available, contact for more details

Tungsten sputtering targets are specialized materials used in physical vapor deposition (PVD) or sputtering. Tungsten sputtering targets include pure Tungsten (W), Tungsten Carbide(WC), Tungsten Disilicide (WSi2), Tungsten Disulfide (WS2), Tungsten Oxide (WO3), and Tungsten Titanium (W/Ti) sputtering target.

Sputtering is a technique where atoms or molecules are ejected from a solid target material and deposited as a thin film on a substrate.

When comparing rotatory targets with planar targets, it is evident that they offer several advantages. They contain more material, leading to greater utilization, longer production runs, and reduced system downtime, thereby increasing the throughput of the coating equipment. Additionally, higher power densities are enabled due to the even spread of heat build-up over the surface area of the target. This results in increased deposition speed and improved performance during reactive sputtering.

Our Tungsten Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.