Menu

MetalsTek Engineering is a premier provider of advanced materials, particularly in Zirconium Carbide. Our precision engineering and quality control expertise ensures that our Zirconium Carbide offerings excel in applications where hardness, thermal stability, and wear resistance are significant.

Material: Zirconium Carbide, ZrC

Purity: 99% and 99.5% (C-11.64%), Plasma Spray Grade

Size: D50 0.5~1μm / 3~5μm / Customized Size

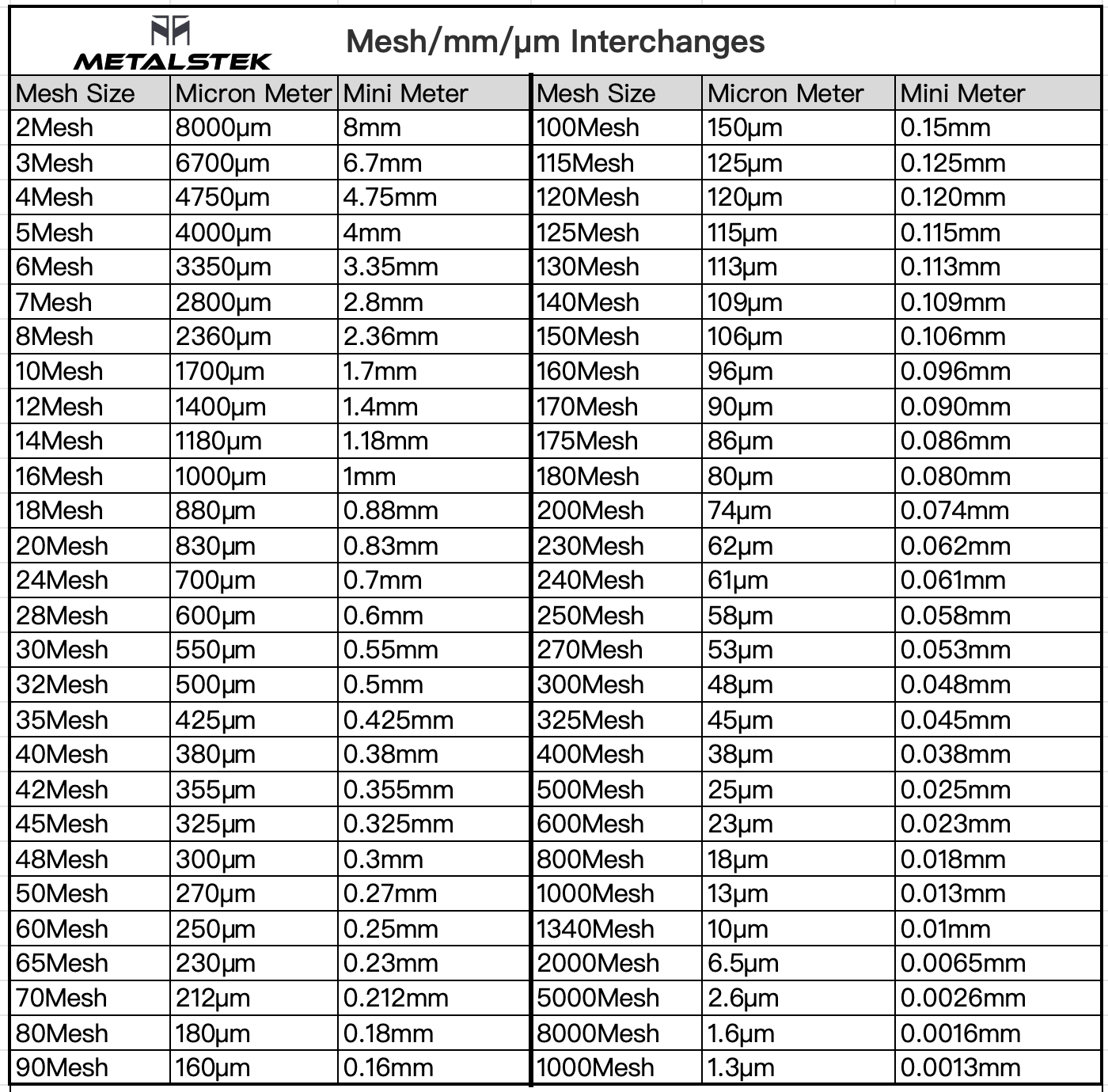

Size Range: 0.5~500μm / 5~400 Mesh, Can be Customized

Temperature: 3,540ºC M.P. / 5,100ºC B.P.

CAS #: 12070-14-3

| Total Carbon | Free Carbon | Nb | Fe | Si | O | N | Na | K | Ca |

|---|---|---|---|---|---|---|---|---|---|

| ≥11.2 | ≤0.50 | 0.005 | 0.05 | 0.005 | 0.5 | 0.05 | 0.005 | 0.005 | 0.05 |

Material: Zirconium Carbide, ZrC

Purity: 99.9%

Temperature: 3,540ºC M.P. / 5,100ºC B.P.

Size: D50 2μm / Customized Size

CAS #: 12070-14-3

| Zr | C | Hf | Fe | Free Carbon | Impurity |

|---|---|---|---|---|---|

| 86.22 | 11.5 | 1.7 | 0.12 | 0.1 | 0.3 |

Material: Zirconium Carbide, ZrC

Purity: 99.9%

Temperature: 3,540ºC M.P. / 5,100ºC B.P.

Size: 30nm, 75 m2/g Specific Surface Area

CAS #: 12070-14-3

Zirconium Carbide (ZrC) is a refractory ceramic material known for its exceptional hardness and resistance to corrosion. It is commercially used in various applications, including cutting tools, metal cladding, cermets, incandescent filaments, and as a coating material for advanced high-temperature nuclear applications. Zirconium Carbide is a tough gray metallic powder with a cubic crystal structure, and it is highly valued for its excellent mechanical properties, making it suitable for use in high-temperature and wear-resistant environments. The material is also known for its resistance to corrosion and oxidation, further increasing its durability and lifespan. Zirconium Carbide is typically produced using efficient and environmentally friendly methods, such as chemical vapor deposition and carbothermal reduction, reducing its environmental impact. Its properties, including a very high melting point, high modulus, and hardness, make it valuable for various industrial applications, including heat exchangers, drying columns, pipe and fittings, pump and valve housings, and nuclear fuel applications.

Zirconium Carbide (ZrC) is a tough refractory ceramic material with a gray metallic powder appearance and a cubic crystal structure. It is known for its exceptional properties, making it valuable for various applications:

Zirconium Carbide’s unique properties, including extreme hardness, high melting point, and corrosion resistance, make it a valuable material for various industrial applications, from nuclear fuel to cutting tools and high-temperature coatings.

Our Zirconium Carbides are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.