Menu

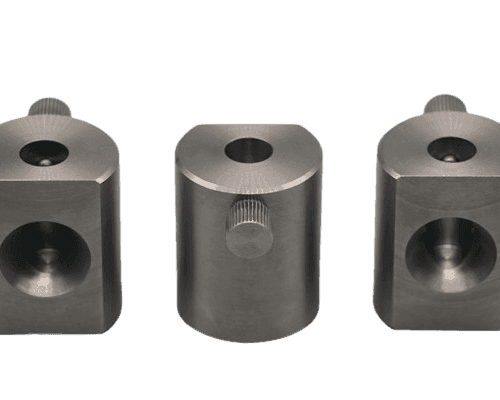

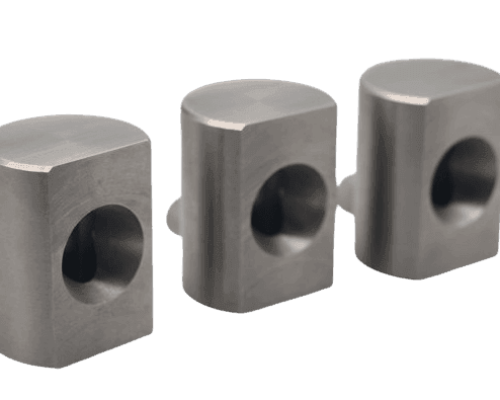

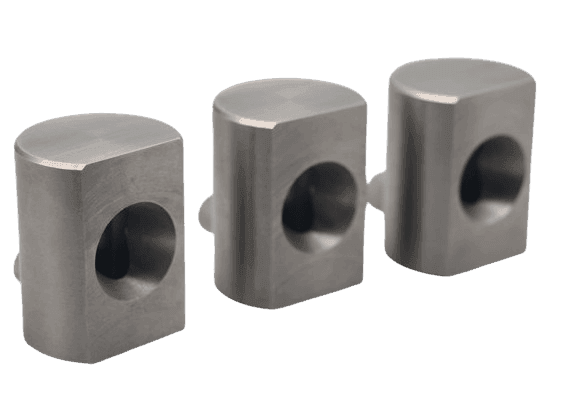

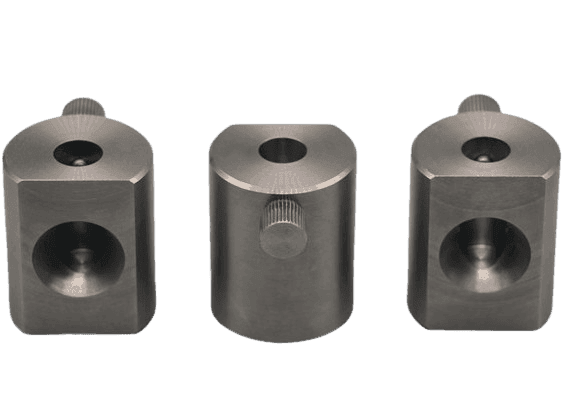

Material: W-Ni-Fe, or Customized

Density: 15.8-18.75 g/cm3

Shape&Size: Per Drawing

Application: Tungsten Alloy Collimators are an important component of industrial radiography. They provide radiation safety to operators and the general public by directing emerging radiation beams into useful irradiation areas.

Tungsten Alloy Collimators are an important component of industrial radiography, providing radiation safety to operators and the general public by directing emerging radiation beams into useful irradiation areas.

Tungsten Alloy Collimators contain and guide the radiation beam during irradiation. This improves the quality of radiographs and safe operating conditions. The tungsten panoramic collimator consists of a stainless steel housing containing two tungsten inserts. The tungsten directional collimator directs the radiation beam out of a side port as a 60-degree cone to the side. All our collimators can be connected directly to the SENTINEL™ source conduit. A wide range of collimators have been developed to suit a variety of applications and technical uses.

Weight: 1.75 lbs (0.79 kg)

Dimensions: Length: 1.88 inches, Diameter: 1.5 inches

Note: Co-60: 0.46 Ir-192: 0.05

Half value layer: Ir-192: 4.30 Co-60: 1.12

Beam size: 60-degree tapered side throw

Tungsten Alloy Collimator is a device that reduces particle beams or light waves. Constriction means that the particle beam is oriented in a specific direction, that is, only rays parallel to the collimator can pass through, or that the space beam fluid is narrowed to limit the amount of radiation.

Tungsten Alloy Collimator is an integral part of the radiation head of medical accelerator. In addition to using primary and secondary collimators, the electron beam current limiting device is equipped with an electron beam current limiter. Its main function is to limit the range of electron radiation to protect target areas beyond normal tissue and make it important. Organs are protected from exposure.

ASTM B777 (MIL-T-21014 / SAE-AMS-T-21014) is a standard specification for Tungsten Heavy Alloys (WHA). The specification is organized into four classes (1-4). Each categorization or classification represents a percentage amount of Tungsten (W) Alloy.

Class 1: W 90%

Class 2: W 92.5%

Class 3: W 95%

Class 4: W 97.5%

| Tungsten Heavy Alloy Grade | WHA-17C | WHA-17F | WHA-175 | WHA-18C | WHA-18F | WHA-185 |

| ASTM B777; AMS-T-21014 Class | Class 1 | Class 2 | Class 3 | Class 4 | ||

| Type | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III |

| AMS 7725C | Type 1 | Type 2 | ||||

| Alloy Composition | 90WNiCu | 90WNiFe | 92.5WNiFe | 95WNiCu | 95WNiFe | 97WNiFe |

| 90% W | 90% W | 92.5% W | 95% W | 95% W | 97% W | |

| 6% Ni | 7% Ni | 5.25% Ni | 3.5% Ni | 3.5% Ni | 2.1% Ni | |

| 4% Cu | 3% Fe | 2.25% Fe | 1.5% Cu | 1.5% Fe | 0.9% Fe | |

| Density (g/cm3) | 17 | 17 | 17.5 | 18 | 18 | 18.5 |

| Density (lbs/in3) | 0.614 | 0.614 | 0.632 | 0.65 | 0.65 | 0.668 |

| Hardness (HRC) | 24~32 | 25~32 | 26~32 | 27~34 | 27~34 | 28~35 |

| Tensile Strength (PSI) | ≥94,000 | ≥110,000 | ≥110,000 | ≥94,000 | ≥105,000 | ≥100,000 |

| Yield Strength (PSI) 2% OFFSET | ≥75,000 | |||||

| Elongation, % in 1” | >2 | >5 | >5 | >2 | >3 | >2 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Modulus of Elasticity (PSI) | 40 x 106 | 45 x 106 | 47 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x 10E-6/°C (20°- 400°C) | 5.4 | 4.8 | 4.6 | 4.4 | 4.6 | 4.5 |

| Thermal Conductivity (cal/s*cm*K) | 0.23 | 0.18 | 0.2 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity (%IACS) | 14 | 10 | 13 | 16 | 13 | 17 |

| Magnetic Properties | NIL | Slightly Magnetic | Slightly Magnetic | NIL | Slightly Magnetic | Slightly Magnetic |

Tungsten alloy shielding is utilized in various medical applications, including:

Our Tungsten Heavy Alloy products are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.