Menu

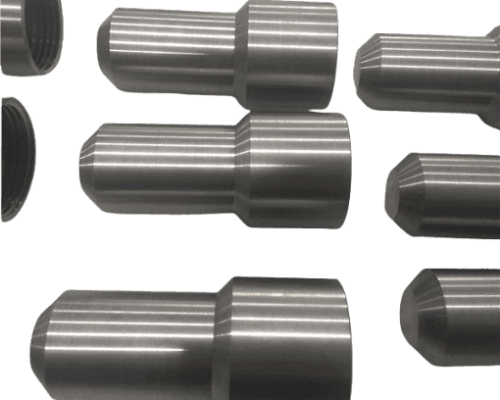

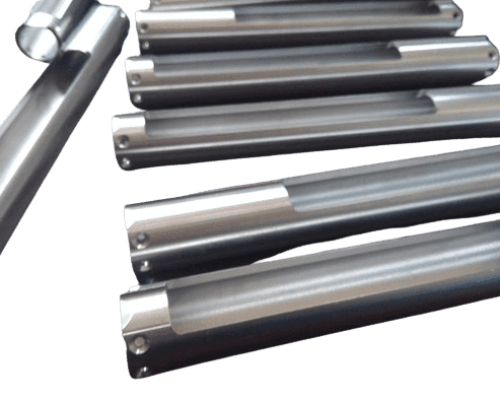

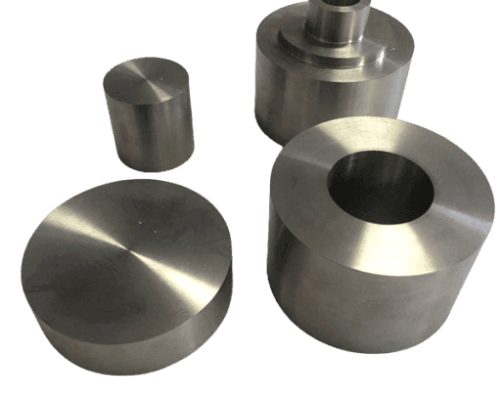

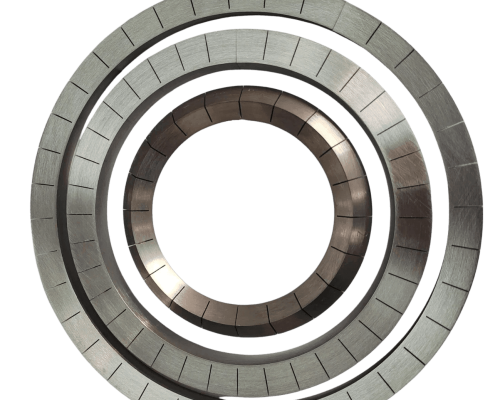

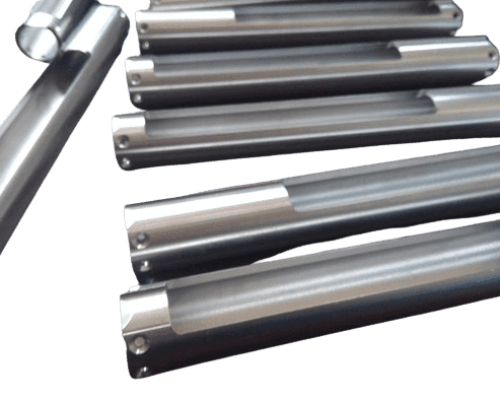

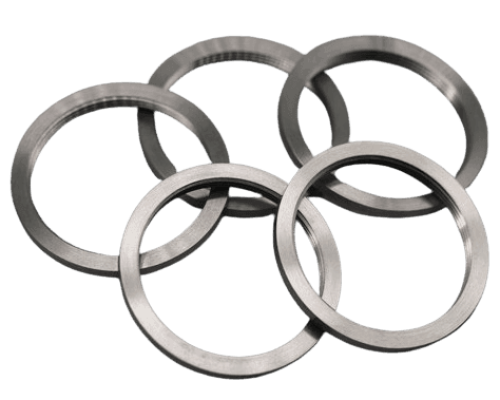

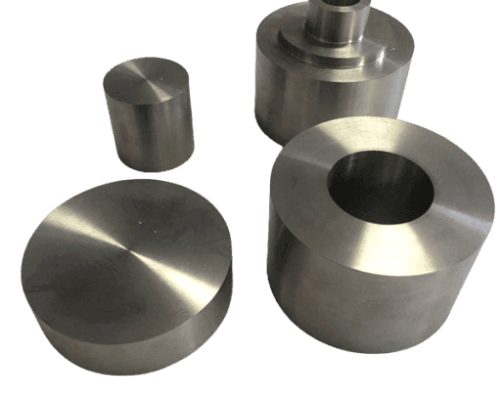

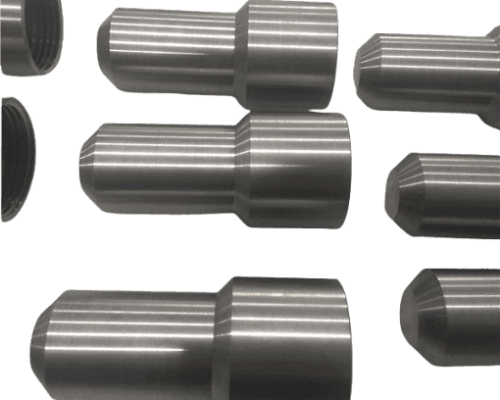

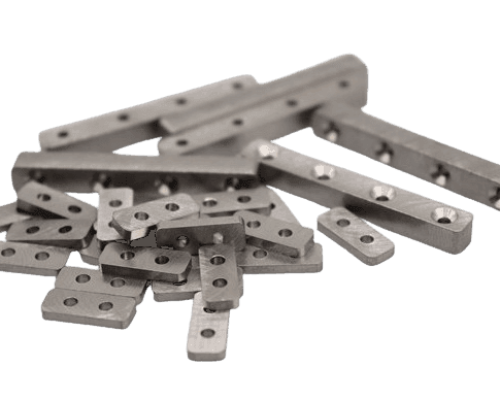

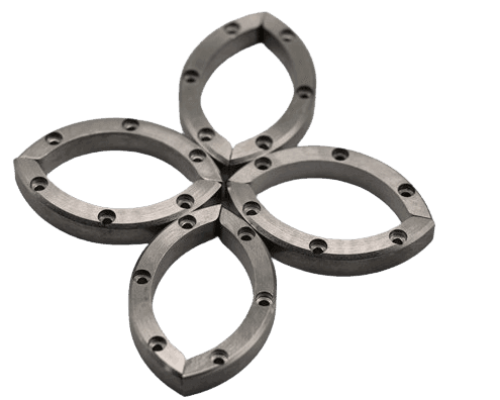

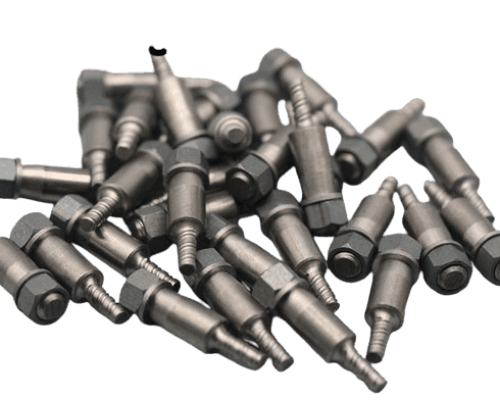

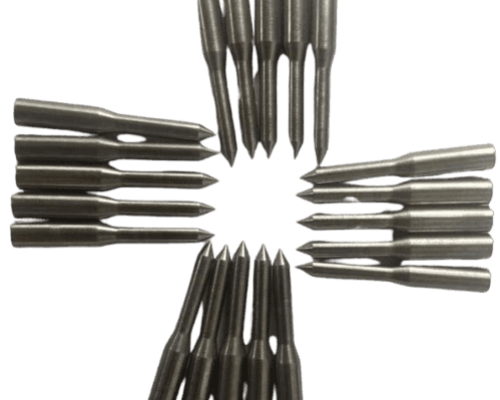

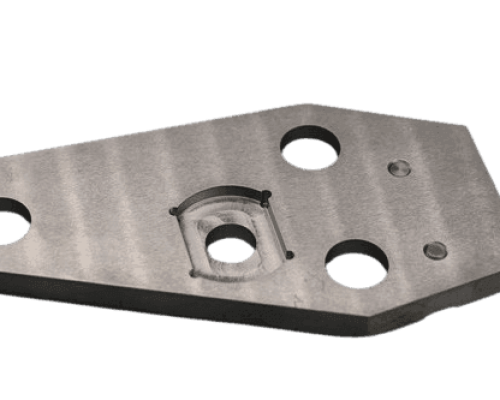

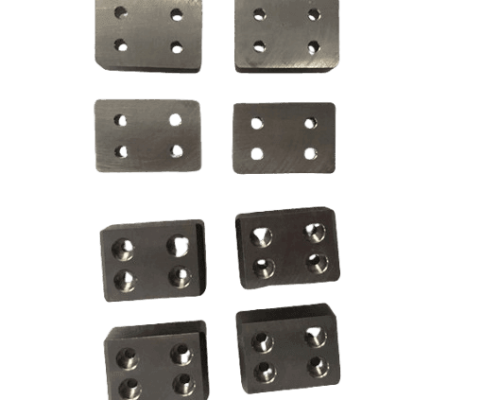

At MetalsTek Engineering, we are experts in providing Custom Tungsten Heavy Alloy Components and Custom Tungsten Machined Parts that meet the highest industry standards. Our custom manufacturing services are designed to deliver precision-engineered tungsten alloy parts, tailored to your unique designs and specifications.

Material: W-Ni-Fe, Tungsten Carbide or Customized

Density: 15.8-18.75 g/cm3

Shape&Size: Per Drawing

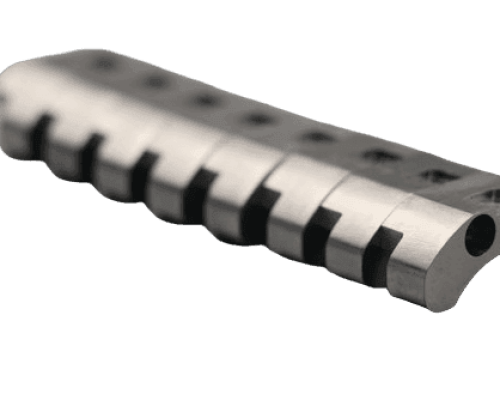

Application: Tungsten Bucking Bar is typically employed on metal rivets to resist the force of hammer blows and absorb the impact generated by rivet guns. This tool provides support, reduces recoil, and minimizes buckling vibration during riveting tasks.

Tungsten alloys are known for their high density, strength, and resistance to extreme temperatures, making them ideal for various industries, including:

ASTM B777 (MIL-T-21014 / SAE-AMS-T-21014) is a standard specification for Tungsten Heavy Alloys (WHA). The specification is organized into four classes (1-4). Each categorization or classification represents a percentage amount of Tungsten (W) Alloy.

Class 1: W 90%

Class 2: W 92.5%

Class 3: W 95%

Class 4: W 97.5%

| Tungsten Heavy Alloy Grade | WHA-17C | WHA-17F | WHA-175 | WHA-18C | WHA-18F | WHA-185 |

| ASTM B777; AMS-T-21014 Class | Class 1 | Class 2 | Class 3 | Class 4 | ||

| Type | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III |

| AMS 7725C | Type 1 | Type 2 | ||||

| Alloy Composition | 90WNiCu | 90WNiFe | 92.5WNiFe | 95WNiCu | 95WNiFe | 97WNiFe |

| 90% W | 90% W | 92.5% W | 95% W | 95% W | 97% W | |

| 6% Ni | 7% Ni | 5.25% Ni | 3.5% Ni | 3.5% Ni | 2.1% Ni | |

| 4% Cu | 3% Fe | 2.25% Fe | 1.5% Cu | 1.5% Fe | 0.9% Fe | |

| Density (g/cm3) | 17 | 17 | 17.5 | 18 | 18 | 18.5 |

| Density (lbs/in3) | 0.614 | 0.614 | 0.632 | 0.65 | 0.65 | 0.668 |

| Hardness (HRC) | 24~32 | 25~32 | 26~32 | 27~34 | 27~34 | 28~35 |

| Tensile Strength (PSI) | ≥94,000 | ≥110,000 | ≥110,000 | ≥94,000 | ≥105,000 | ≥100,000 |

| Yield Strength (PSI) 2% OFFSET | ≥75,000 | |||||

| Elongation, % in 1” | >2 | >5 | >5 | >2 | >3 | >2 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Modulus of Elasticity (PSI) | 40 x 106 | 45 x 106 | 47 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x 10E-6/°C (20°- 400°C) | 5.4 | 4.8 | 4.6 | 4.4 | 4.6 | 4.5 |

| Thermal Conductivity (cal/s*cm*K) | 0.23 | 0.18 | 0.2 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity (%IACS) | 14 | 10 | 13 | 16 | 13 | 17 |

| Magnetic Properties | NIL | Slightly Magnetic | Slightly Magnetic | NIL | Slightly Magnetic | Slightly Magnetic |

Our Tungsten Heavy Alloy products are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.