Menu

MetalsTek Engineering is a leading supplier of Copper products. We offer competitive pricing and excellent lead times on all our materials, and we can supply custom materials per any specs/drawings you provide.

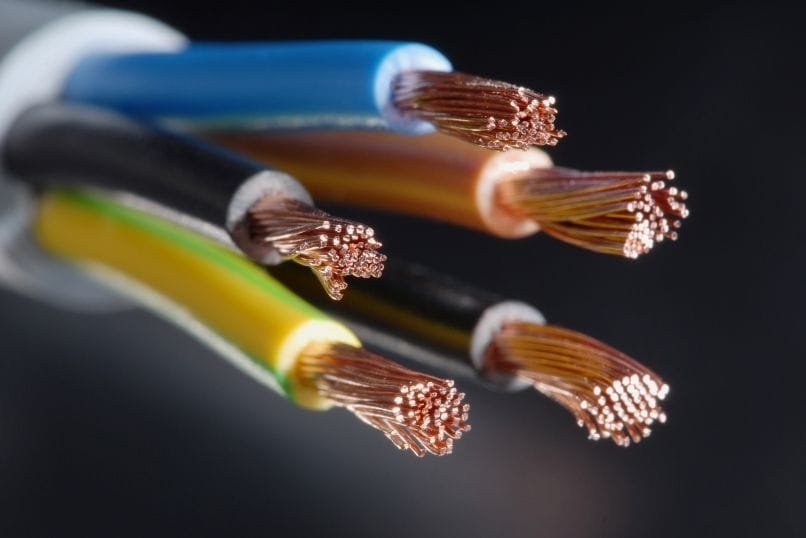

Copper, known for its reddish-brown color and excellent conductivity, is a versatile metal with various applications. It’s a fundamental material in electrical wiring and electronics due to its high conductivity and malleability. Beyond its electrical uses, copper is essential in plumbing, roofing, and architectural design due to its corrosion resistance and durability. It’s also a crucial component in various alloys, enhancing properties such as strength and corrosion resistance in metals like brass and bronze. Additionally, its antimicrobial properties find applications in healthcare settings. Copper’s versatility, conductivity, and durability make it an indispensable material across multiple industries.

Copper Evaporation Materials

Cu, Al/Cu, Al/Si/Cu, Cr/Cu, Cu/Co, Cu/Ga, Cu/Ge, Cu/In, Cu/Ni, Cu/Zn, Mn/Cu, Zr/Cu, CuS Evaporation Materials, etc.

Purity: ≥99.9%

Copper Metals

Spherical Copper Powder, Copper Foil, Copper Metal, Copper Chops, Copper Bonding Wire, Copper Shaped Bar, Copper Strip.

Purity: 2N-5N, or customized.

Copper Alloys

Titanium Clad Copper Parts, Al-Cu Master Alloy, Brass Powder, Brass Wire Mesh, Bronze Wire Mesh, Copper Wire Mesh, Nickel Aluminum Bronze, 260 Brass Rolls, 110 Copper Rolls, 510 Bronze Rolls, etc.

Copper Compounds & Catalysts

Copper Oxide Powder, Copper Sulfide Powder, Copper Nitride Powder, Calcium Copper Titanate Powder, Copper Acetylacetoneate, Copper Phthalocyanine, and Copper Chloride.

Purity: 99%

| Phase At STP | Solid | Electrical Resistivity | 16.78 nΩ⋅m (20°C) |

| Melting Point | 1,357.8K (1,084.6°C/1,984.3°F) | Magnetic Ordering | Diamagnetic |

| Boiling Point | 2,835K (2,562°C, 4,643°F) | Young’s modulus | 110–128 GPa |

| Density (Near R.T.) | 8.96 g/cm3 | Shear Modulus | 48 GPa |

| Appearance | Red-orange metallic luster | Bulk Modulus | 140 GPa |

| Heat Of Fusion | 13.26 kJ/mol | Poisson Ratio | 0.34 |

| Heat Of Vaporization | 300.4 kJ/mol | Mohs Hardness | 3 |

| Molar Heat Capacity | 24.440 J/(mol·K) | Vickers Hardness | 343–369 MPa |

| Thermal Expansion | 16.5 µm/(m⋅K) (at 25 °C) | Brinell Hardness | 235–878 MPa |

| Thermal Conductivity | 401 W/(m⋅K) | Cas Number | 7440-50-8 |

Copper, with its exceptional properties, finds diverse applications across various industries:

Copper’s versatility, conductivity, and resistance to corrosion make it an indispensable metal across numerous sectors, contributing significantly to modern society.