Menu

MetalsTek Engineering is a leading supplier of Molybdenum products such as metals, alloys, compounds, and more. We offer competitive pricing and excellent lead times on all our materials, and we can supply custom materials per any specifications or drawings you provide us.

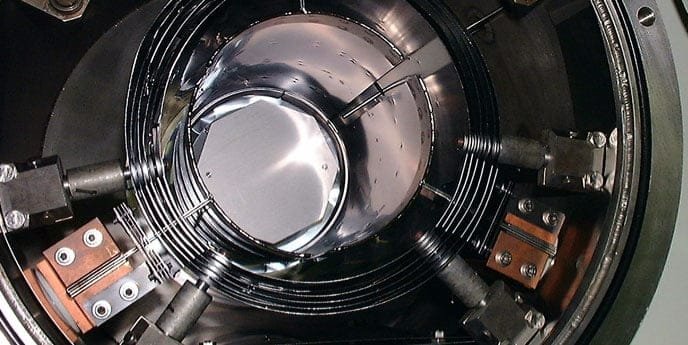

Molybdenum, also known as Moly, is a transition metal with a metallic grey appearance and impressive physical properties, according to the Periodic Table. It is known for its exceptional durability and strength as it has a melting point of 2,617°C, a density of 10.2 g/cc, and a vapor pressure of 10-4 Torr at 2,117°C. Molybdenum is primarily used as an alloying element to enhance the corrosion resistance of various materials. It is widely incorporated into aircraft components, tools, and electrical contacts due to its high melting point and robustness. Additionally, Molybdenum is ideal for producing advanced displays, semiconductors, and sensors under vacuum conditions.

This versatile metal is crucial in multiple industries, including aerospace, technology, and manufacturing. It creates resilient, high-performance materials essential for advancements.

Molybdenum Metals

Molybdenum Rod/Bar/Sheet/Plate/Wire/Disc/Square/Crucible/Electrode/Boat/Fastener/ Powder.

Purity: ≥99%

Molybdenum Alloys

TZM Alloy, Mo-La Alloy, Re-Mo Alloy, Mo-Nb Alloy, Al-Mo Alloy, Fe-Mo Alloy, ZHM Alloy, MHC Alloy, Mo-W Alloy, Cu-Mo Alloy, Mo-Ni Master Alloy, etc.

Available in various forms.

Molybdenum Evaporation Materials

Molybdenum (Mo) Evaporation Materials, Cr/Mo Evaporation Materials, Mo/Al Evaporation Materials, Mo/Ti Evaporation Materials, Ta/Mo Evaporation Materials, MoO3 Evaporation Materials.

Purity: ≥99.9%

Other Molybdenum Products

MoS2 Crystal, MoTe2 Crystal, MoSe2 Crystal, MoSSe Crystal, MoWS2 Crystal.

Purity: ≥99.9%

| Phase At Stp | Solid | Electrical Resistivity | 53.4 nΩ⋅m (at 20 °C) | |

| Melting Point | 2,896 K (2,623 °C/4,753 °F) | Magnetic Ordering | Paramagnetic | |

| Appearance | Grey, Metallic | Young's Modulus | 329 GPa | |

| Density (Near R.T.) | 10.28 g/cm3 | Shear Modulus | 126 GPa | |

| When Liquid (At M.P.) | 9.33 g/cm3 | Bulk Modulus | 230 GPa | |

| Heat Of Fusion | 37.48 kJ/mol | Poisson Ratio | 0.31 | |

| Heat Of Vaporization | 598 kJ/mol | Mohs Hardness | 5.5 | |

| Molar Heat Capacity | 24.06 J/(mol·K) | Vickers Hardness | 1,400–2,740 MPa | |

| Thermal Expansion | 4.8 µm/(m⋅K) (at 25 °C) | Brinell Hardness | 1,370–2,500 MPa | |

| Thermal Conductivity | 138 W/(m⋅K) | Cas Number | 7439-98-7 | |

| Thermal Diffusivity | 54.3 mm2/s (at 300 K) | Z Ratio | 0.257 |

Molybdenum, recognized for its diverse properties, is pivotal in several industries due to its unique characteristics and versatility. The typical applications include:

Molybdenum’s versatility, strength, and resistance to high temperatures and corrosion make it an indispensable material in multiple industries, contributing significantly to technological advancements, manufacturing, and material science.