Menu

When selecting a heat source, it is crucial to consider the size and properties of the material you want to heat. Chrome plated rods are typically used only once and are made of 99% pure chrome. Before making a decision, make sure to check the power requirements and shape of each heat source.

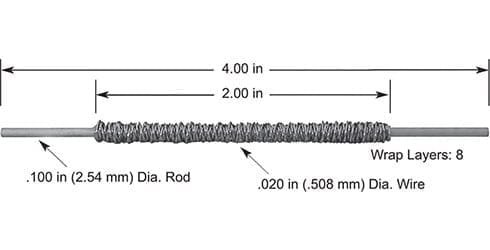

#188: 148 Amps, 166 Watts

#189: 149 Amps, 177 Watts

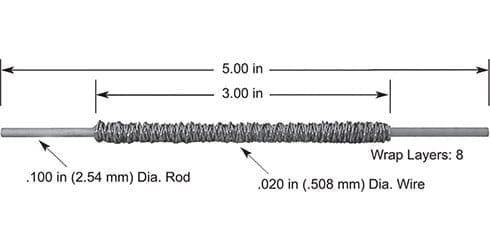

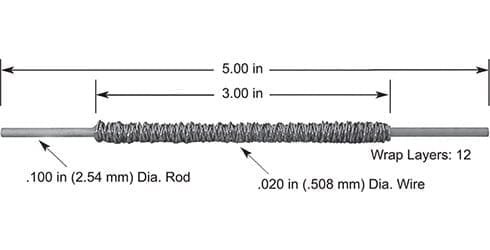

5″ Long x 0.100″ Diameter Wrapped with 12 Layers of 0.020″ Diameter W Wire for 3″

#190: 172 Amps, 224 Watts

#191: 223 Amps, 807 Watts

Tungsten thermal evaporation rods offer an effective way to deposit thin films of various materials in high vacuum coating systems. Tungsten is an ideal material for evaporation sources due to its unique properties.

Chromium plated tungsten rods are commonly used for depositing chromium thin films. The chrome plating provides better thermal efficiency and control over film thickness compared to chromium chips.

The rods are available in different diameters with a thin chromium coating. Common lengths are chosen to fit popular evaporation source holders.

Tungsten rods require relatively low power to reach high temperatures suitable for evaporation. This eliminates issues like spitting and spalling that can occur with other chromium evaporation methods.

In addition to chromium, tungsten rods can be used to evaporate other materials that are difficult to evaporate using boats or baskets due to their high melting points.

In summary, chromium-plated tungsten rods provide a user-friendly and effective way to thermally evaporate chromium and other high melting point materials in vacuum coating systems. Their unique properties make them suitable for depositing high-quality thin films.