Menu

MetalsTek Engineering holds a wide variety of Cobalt Alloys. Below are the typical ten types. For more Cobalt Alloys, please Talk to An Expert.

Compositions: Cobalt Chromium Tungsten

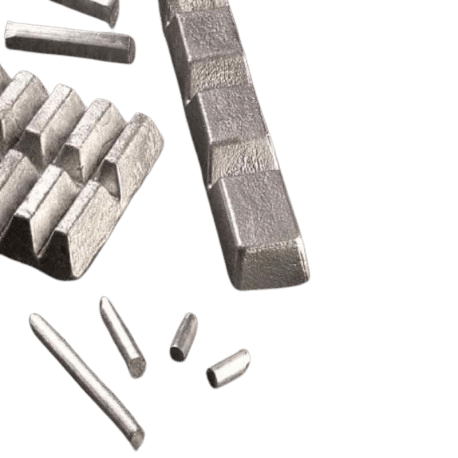

Product Form: Powder, Ingot, Rod, Sheet, and More

Size: Tailored Sizes, 100~500 Mesh for Powder

Main Applications: Plasma Overlaying, Spraying

| Item No. | HRC | Co | Cr | W | C | Fe | Mo | Ni | Si | Mn |

|---|---|---|---|---|---|---|---|---|---|---|

| Co27-01 | 48-54 | Bal | 30 | 12 | 2.4 | ≦3.00 | ≦1.00 | ≦3.00 | 1 | ≦1.00 |

| Co27-02 | 48-54 | Bal | 30 | 12 | 2.3 | ≦3.00 | / | ≦3.00 | 1 | / |

| Co27-03 | Bal | |||||||||

| Co27-04 | 38-44 | Bal | 30 | 4.5 | 1.2 | ≦3.00 | ≦1.00 | ≦3.00 | 1 | ≦1.00 |

| Co27-05 | Bal | 28 | 4.0 | 1.6 | 1.1 | |||||

| Co27-06 | 43-48 | Bal | 30 | 5.5 | 1.3 | 3.00Max | 0.8 | 3.0Max | 1.5 | 1.0Max |

| Co27-07 | 42-48 | Bal | 29 | 8.5 | 1.4 | ≦3.00 | ≦1.00 | ≦3.00 | 1.4 | ≦1.00 |

| Co27-08 | 45-49 | Bal | 30 | 5.5 | 1.3 | 3.0Max | 5 | 11 | 1 | 1.0Max |

| Co27-09 | 48-53 | Bal | 30 | 7 | 1.7 | 2.0Max | 2.0 | 3.0Max | 1.7 | 0.5Max |

| Co27-10 | 43-48 | Bal | 27 | 1.8 | 4.0 | 6.0 | Nb:5.0 | |||

| Co27-11 | 40-44(46-50) | Bal | 35 | 5 | 2.0 | 2.0Max | 24 | 1 | 1 | |

| Co27-12 | 48-56 | Bal | 31 | 11 | 1.8 | 3.0Max | 3.0Max | 1.0 | 1.0 | |

| Co27-13 | 37-44 | Bal | 26 | 12 | 1.6 | 3.Omax | 0.5Max | 23 | 1.1 | O.5Max |

| Co27-14 | 38-44 | Bal | 28 | 12 | 1.4 | 3.0Max | 0.8 | 23 | 1.2 | 0.5 |

| Co27-15 | 57-53 | Bal | 32 | 18 | 2.5 | ≦3.00 | ≦1.00 | ≦3.00 | 1 | ≦1.00 |

| Co27-16 | 30-36 | Bal | 26 | 5.5 | 0.4 | 3.0Max | 3.0Max | 0.9 | 0.3 | |

| Co27-17 | 30-35 | Bal | 25.5 | 7.5 | 0.8 | 1.0Max | 1.0Max | 11 | 0.4 | 0.5Max |

| Co27-18 | 30-35 | Bal | 25.5 | 7.5 | 0.4 | 2.0Max | 0.5Max | 11 | 0.8 | 0.5Max |

| Co27-19 | 47-53 | Bal | 28 | 19 | 1.0 | 2.5Max | 1 | 1 | ||

| Co27-20 | 20Max | Bal | 20 | 15 | 0.05Max | 3.0Max | 0.8 | 10 | 0.8 | 1.3 |

| Co27-21 | 34-40 | Bal | 25 | 2.5 | 0.4 | 4.0Max | Nb:7.0 | 6.0 | 1 | 1.0 |

| Co27-22 | 20-26 | Bal | 26 | 0.1 | 20 | 3.0 | 1 | 1.0 | ||

| Co27-23 | 57-63 | Bal | 26 | 14 | 3.3 | 3.0Max | 1.0Max | 3.0Max | 0.8 | 1.0Max |

| Co27-24 | 48-54 | Bal | 8.5 | 0.08Max | 2.0Max | 29 | 1.0Max | 2.5 | 0.5Max | |

| Co27-25 | Bal | 14 | 0.08Max | 0.5Max | 26 | 0.5 | 2.6 | 0.1Max | ||

| Co27-26 | 52-58 | Bal | 17.5 | 0.08Max | 2.0Max | 29 | 1.0Max | 3.5 | 0.5Max | |

| Co27-27 | 46-52 | Bal | 17 | 0.08Max | 0.5Max | 22 | 0.5Max | 1.2 | 0.5Max |

Applications

Cobalt-based Alloy Powder (Co-Cr-W) can be applied to a various process, such as:

-oxyacetylene spraying or overlaying

-HVOF/HAFA spraying

-plasma transferred arc (PTA) overlaying

-plasma spraying

-laser overlaying

-induction melting overlaying

Compositions: Cobalt Chromium Molybdenum

Product Form: Powder, Ingot, Rod, Sheet, and More

Size: Tailored Sizes, 100~500 Mesh for Powder

Main Applications: Plasma Overlaying, Spraying

| Item No. | HRC | Co | Cr | Mo | Fe | Ni | C | Mn | Si |

|---|---|---|---|---|---|---|---|---|---|

| Co27M-01 | 38-43 | Bal | 29 | 5 | 3.0Max | 3.0Max | 1.2 | 1.0 | 0.5 |

| Co27M-02 | 40-46 | Bal | 31 | 5.5 | 2.0Max | 2.0Max | 1.6 | 1.0 | 0.5 |

| Co27M-03 | 45-50 | Bal | 29 | 9.0 | 3.0Max | 3.0Max | 1.8 | 0.5 | 0.5 |

| Co27M-04 | 50-56 | Bal | 31 | 13.0 | 3.0Max | 3.0Max | 2.5 | 0.5 | 0.5 |

| Co27M-05 | 54-60 | Bal | 33 | 18 | 3.0Max | 3.0Max | 2.5 | 0.8 | 0.5 |

| Co27M-06 | 18-24 | Bal | 30 | 4.0 | 8.0 | 0.3Max | 0.05Max | 0.7 | 0.6 |

Material: HAYNES Alloy 188, UNS R30188

Composition: Co-Cr(20%~24%)-Ni(20%~24%)-W(13%~15%)-Fe(<3%)-C(<0.15%)

Properties: 9.14g/cc Density, 1,300°C M.P.

Feature: Oxidation Resistance Up to 1,095°C

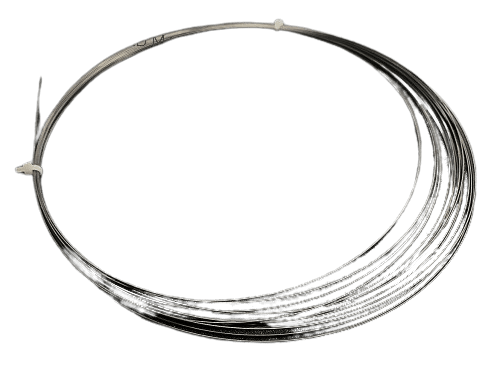

Forms: Wire, Rod, Tube, Sheet, Plate, Flange, Machined Parts

Main Applications: Turbine Engines, Combustor Cans, Flame Holders, Liners

Material: Cobalt Based Alloy

Grade: 1, 6, 12, 21

Form: Welding Rod, Seal Ring, Sheet, Plate

Feature: High Wear & Corrosion Resistance

Other: Stellite is a trademark of Haynes International

Material: HY-180 High Strength Alloy Steel

Composition: Fe78.72%, Ni10%, Co8%, Cr2%, Mo1%, C0.13%, Mn0.1%, Si0.05%

Density: 7.75g/cc

Form: Rod, Bar, Sheet, Plate, Machined Parts

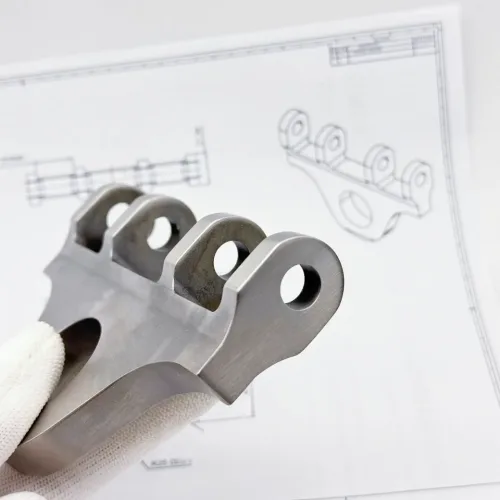

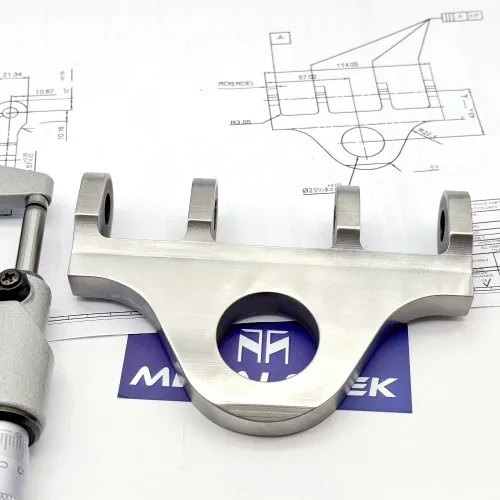

Applications: Aerospace, Automotive, Defence, Vehicle Components, Structural Engineering, Industrial Machinery

Typical Industry Specification: vehicle components, structural engineering, industrial machinery, and aerospace structures

HY-180 is a premium-grade alloy steel, recognized for its outstanding strength, toughness, and wear resistance. With a carefully balanced composition and a production process optimized for performance, HY-180 offers unparalleled reliability for applications in heavy machinery, automotive, and other high-stress environments.

HY-180 alloy steel features a precise blend of elements, ensuring superior mechanical properties:

Available in a wide range of sizes and forms, including sheets, bars, rods, and custom-machined components.

HY-180 is manufactured using advanced metallurgical techniques to ensure precision and quality:

HY-180 High Strength Alloy Steel is a versatile material used across a range of industries:

By selecting HY-180, you’re investing in:

Model: CoNi, CoFe, CoCrNiMo, CoCrTa, CoCrNiAl, CoCrNiFeMo, CoCrNiMnAl, and More

Product Form: Powder, Ingot, Wire, Rod, Tube, Sheet, Plate, Flange, Machined Parts

Cobalt Alloys are a group of metallic materials composed primarily of cobalt, often with the addition of other elements such as chromium, nickel, tungsten, iron, and more. These alloys are renowned for their exceptional mechanical properties, including high strength, hardness, and corrosion resistance, making them invaluable in various industrial applications. Common types of cobalt alloys include Stellite alloys, known for their wear and corrosion resistance in cutting tools and aerospace components; Haynes alloys, prized for their high-temperature strength and oxidation resistance in gas turbine engines and industrial applications; and cobalt-chromium dental alloys, utilized for their biocompatibility and durability in dental prosthetics. Additionally, cobalt alloys are extensively used in medical implants, aerospace components, magnetic applications, and wear-resistant tools, demonstrating their versatility and importance in modern engineering and manufacturing.

Cobalt Alloys find extensive applications across various industries due to their exceptional properties, including high strength, corrosion resistance, and wear resistance. Some typical applications of cobalt alloys include:

Cobalt alloys play a vital role in various industrial sectors, developing high-performance components and equipment requiring exceptional mechanical properties and reliability.

Our Cobalt Alloys are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent damage during storage or transportation.