Menu

MetalsTek Engineering is a Worldwide manufacturer and supplier of Cobalt and Alloy Rods. We can provide high-quality cobalt products with short lead times and competitive prices.

Material: Cobalt, CAS # 7440-48-4

Purity: 99%, 99.9%, 99.95%, 99.99%

Size: Rod – Diameter 3.00~80mm * Length<2,000mm

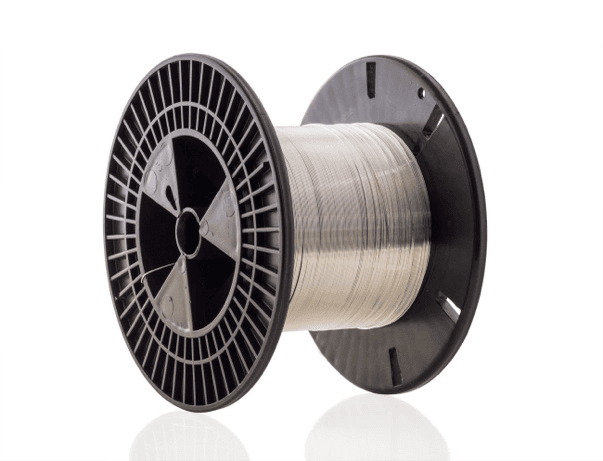

Wire – Diameter 0.05~3.00 mm * Length

Material: HAYNES Alloy 188, UNS R30188

Composition: Co-Cr(20%~24%)-Ni(20%~24%)-W(13%~15%)-Fe(<3%)-C(<0.15%)

Properties: 9.14g/cc Density, 1,300°C M.P.

Feature: Oxidation Resistance Up to 1,095°C

Main Applications: Turbine Engines, Combustor Cans, Flame Holders, Liners

Cobalt Rod is a metallic product composed of cobalt, often used in its pure form or as part of an alloy. Cobalt is known for its unique properties, including high melting point, strength at elevated temperatures, magnetic properties, and resistance to wear, corrosion, and thermal shock. These characteristics make cobalt rods valuable in various applications across multiple industries.

Cobalt rods are produced through industrial processes, including melting, casting, and forging or extrusion, followed by drawing or rolling to achieve the desired diameter and surface finish. The specific process can vary depending on the intended application and the required properties of the final product. For instance, alloying cobalt with other elements can enhance its strength, corrosion resistance, or magnetic properties.

Our Cobalt Rods are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent damage during storage or transportation.