Menu

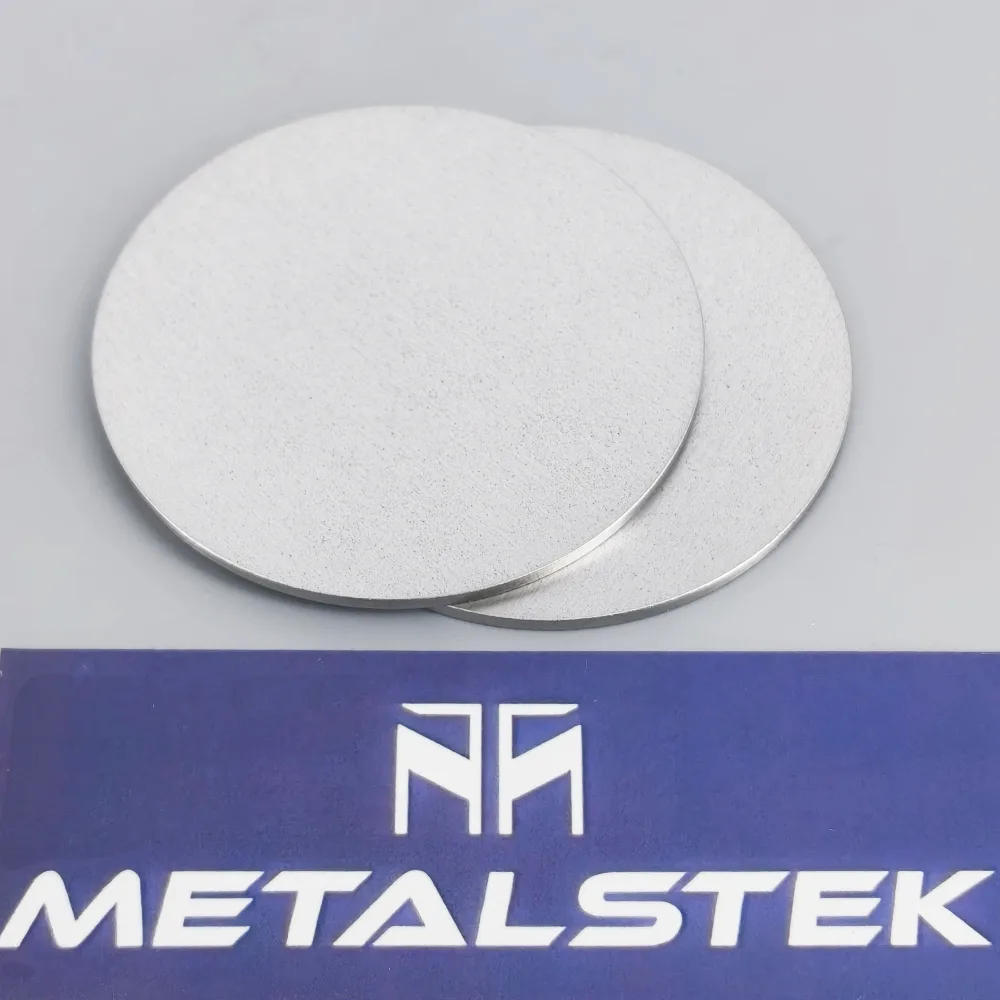

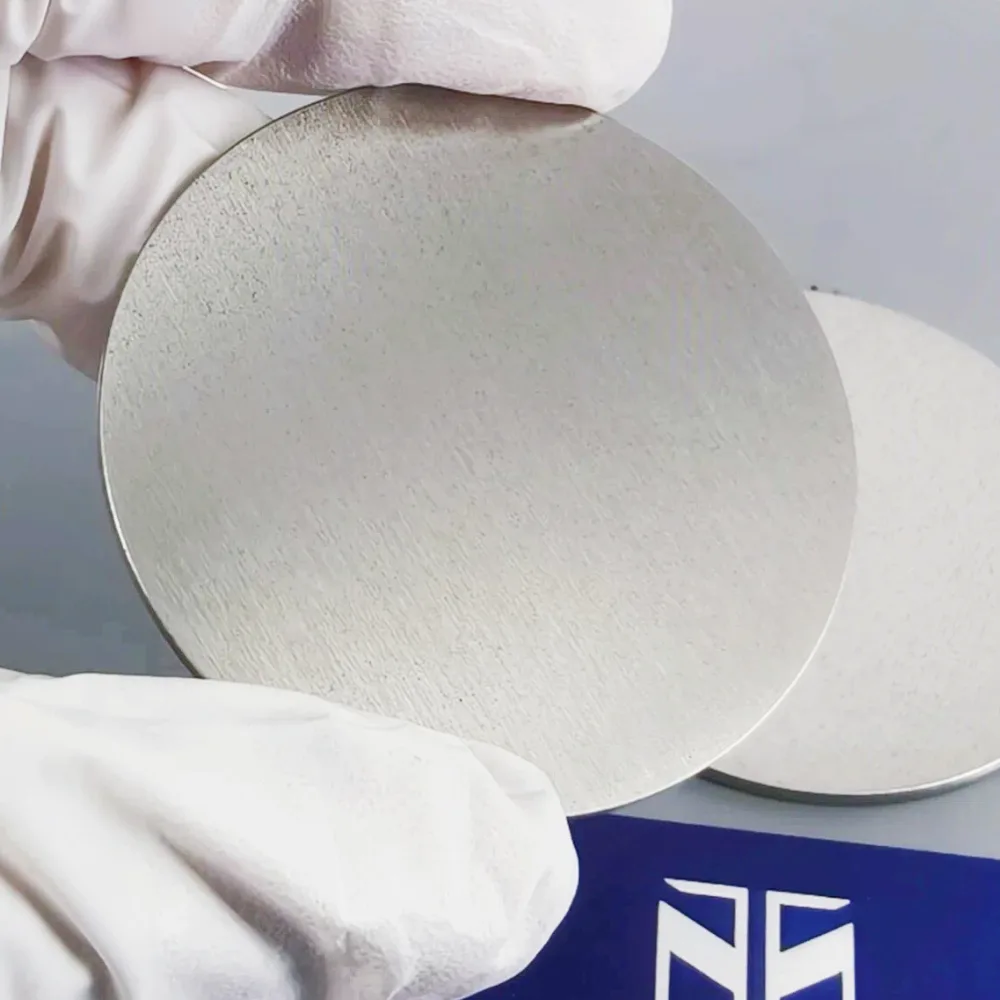

MetalsTek Engineering takes great pride in advancing Cobalt Sputtering Targets. Our expertise and use of cutting-edge technologies allow us to achieve innovation and excellence in the industry. We are trusted by leading manufacturers worldwide and set the standard for excellence in Cobalt Sputtering Targets. Our solutions are designed to propel businesses forward, paving the way for technological advancements.

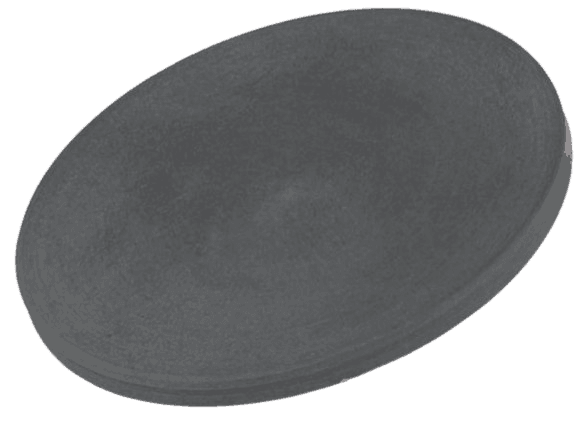

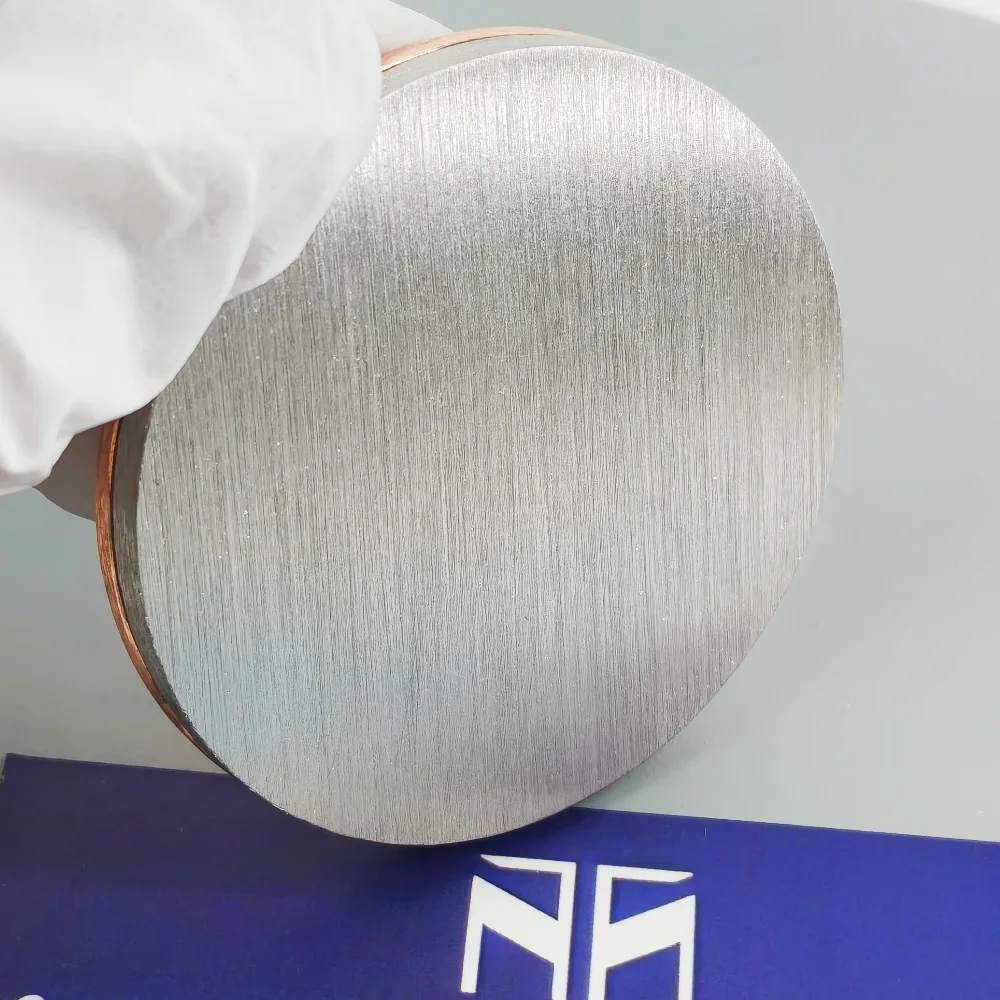

Material: Cobalt, 99.9%, 99.95%, 99.99%

Properties: Grayish Metallic, 1,495°C M.P., 8.9 g/cc Density; 100 W/m.K Thermal Conductivity, DC Sputter, 13.0*10-6/K Coefficient of Thermal Expansion

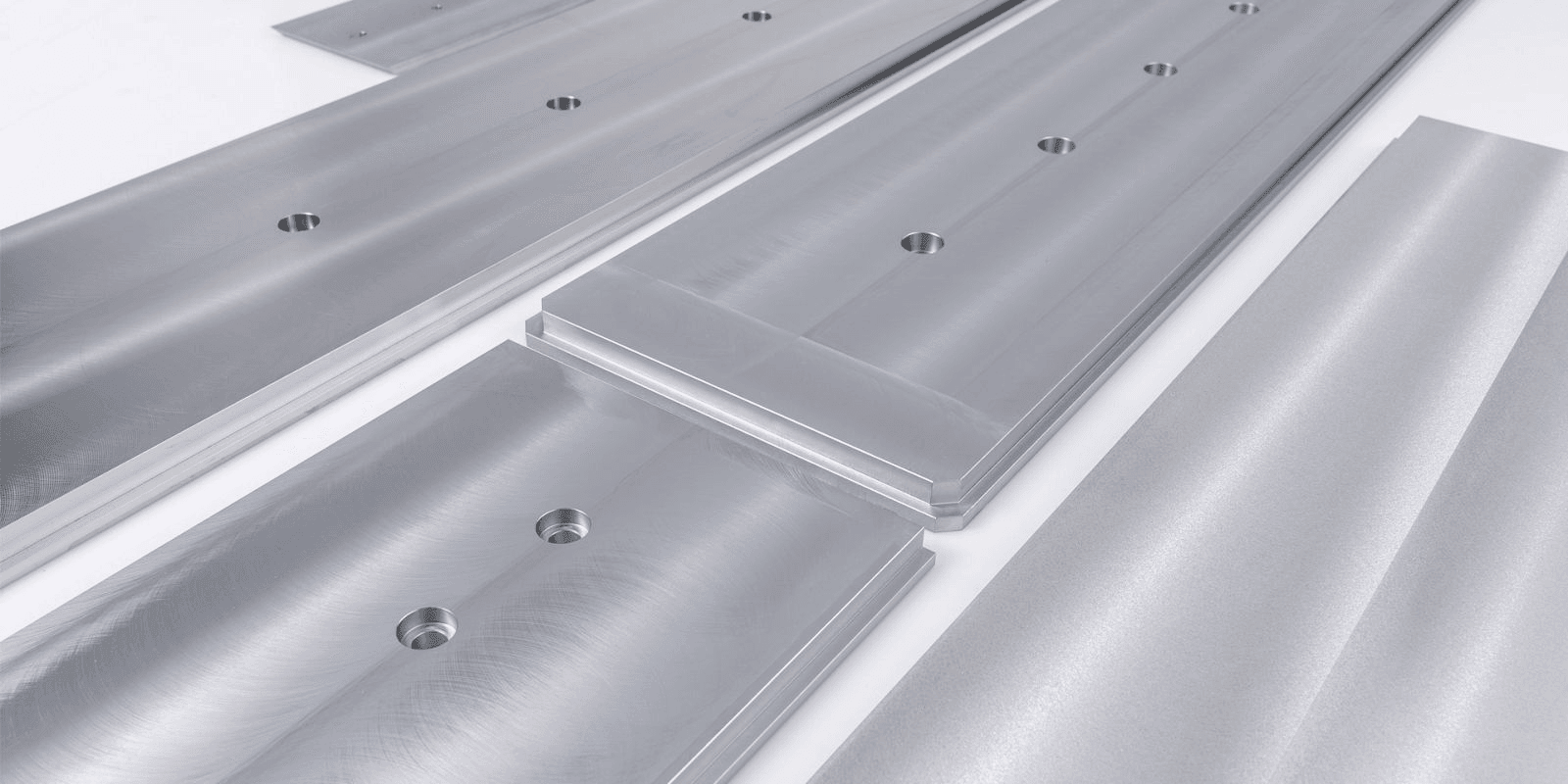

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: CoO- 99.9%~99.99%; / Co3O4 – 99.9%~99.999%

Properties: Co3O4 – Black, 895°C M.P., 6.11g/cc Density; 240.80 M.W.

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium Recommended

Material: Cobalt Aluminum

Purity: Co/Al or Al/Co, 99.9% ~ 99.95%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Chromium Cobalt

Purity: Co/Cr or Cr/Co, 99.9% ~ 99.99%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Iron Cobalt

Purity: Co/Fe, 99.9% ~ 99.95%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Cobalt Nickel

Purity: Co/Ni, 99.9% ~ 99.99%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Copper Cobalt

Purity: Cu/Co, 99.9% ~ 99.99%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Cobalt Titanium

Purity: Co/Ti, 99.9% ~ 99.99%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Cu/W, 99.9% ~ 99.95%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Co/Pt, 99.9% ~ 99.999%

Properties: 254.02 M.W., 1,680-1,770℃ M.P.

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Co/Ni/Cr, 99.9% ~ 99.95%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Cobalt Chromium Nickel Alloy, 99.9%~99.999%

Properties: Metallic, 9.7g/cc Density, 13 µm/m-K Thermal Expansion

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium

Material: Co/Cr/Fe/Ni/Al, 99.9% ~ 99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

The CoCrFeNiAl High-Entropy Alloy (HEA) Sputtering Target is a critical material used in the sputter deposition process, which is widely employed in the semiconductor and thin-film industry. This technique involves depositing thin layers of materials on a substrate, which is a crucial step in the manufacturing of electronic devices such as integrated circuits and photovoltaic cells. Additionally, it plays a crucial role in creating protective coatings applied to various surfaces. The versatility of sputter deposition makes it indispensable across a range of applications, facilitating the production of high-performance electronic components and enhancing the durability of surfaces in diverse settings.

The CoCrFeNiAl HEA Sputtering Target is composed of a combination of cobalt, chromium, iron, nickel, and aluminum, and it truly exemplifies the innovative potential of high-entropy alloys. These materials are a new class of alloys known for their exceptional properties, including remarkable strength, superior corrosion resistance, and robust thermal stability. However, due to certain characteristics of the CoCrFeNiAl alloy, such as brittleness and low thermal conductivity, special handling precautions are necessary. Indium bonding is recommended to address these challenges and ensure optimal performance during the sputtering process.

Despite its unique handling requirements, the CoCrFeNiAl HEA Sputtering Target remains indispensable in various applications within the electronics industry and beyond. Its versatility and exceptional properties make it a preferred choice for manufacturers seeking high-quality thin films and protective coatings. With its ability to enhance the performance and longevity of electronic devices and surface materials, this sputtering target plays a pivotal role in advancing technological innovation and meeting the demands of modern industrial applications.

Material: Co/Cr/Fe/Ni/Mn, 99.9% ~ 99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium Recommended

Applications: Electronic Devices, Photovoltaic Cells, and Coatings

Material: Co/Fe/B, 99.9% ~ 99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium Recommended

Cobalt Iron Boron Sputtering Target is made by combining cobalt, iron, and boron in the desired ratio and then compacting and sintering the mixture into a solid target form. The target is then mounted inside a sputtering system, where it is bombarded with high-energy ions to release atoms that deposit onto the substrate.

Material: Co/Ni/V, 99.9% ~ 99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium Recommended

The CoNiV High-Entropy Alloy (HEA) Sputtering Target is a specialized material utilized in the sputter deposition process, particularly in industries like semiconductor manufacturing and thin-film coating. Sputter deposition is a widely employed technique for applying thin layers of material onto a substrate, playing a vital role in the fabrication of various electronic devices, photovoltaic cells, and surface coatings.

High-entropy alloys (HEAs) represent a distinct class of materials renowned for their unique properties, which stem from their composition of multiple elements in roughly equal proportions. Depending on the specific combination of elements employed, these alloys can demonstrate outstanding mechanical strength, corrosion resistance, and thermal stability.

Handling Notes

Due to certain characteristics such as brittleness and low thermal conductivity that are not conducive to sputtering, it is recommended to use indium bonding for the CoNiV High-Entropy Alloy (HEA) Sputtering Target. Additionally, this material exhibits low thermal conductivity and is prone to thermal shock.

Cobalt Niobium Zirconium Sputtering Target, Co/Nb/Zr

Material: Co/Ta/Zr, 99.99%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: Co/Tb/Fe, 99.9%~99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: CoSi2, 99.9%~99.999%

Properties: Black, 4.9g/cc Density, 115.1 M.W.

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: CoFe2O4, 99.9%~99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: LiCoO2 >99.7%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: LiNi(1-x)CoxO2, 99.9%~99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: LaxSr1-xCoyFe1-yO3, 99.9%~99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: MnCo2O4, 99.9%~99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Material: SrCoO3, 99.9%~99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤12” * Length≤14”

Bonding: Indium, Elastomer

Cobalt Sputtering Targets have many applications in producing thin films for various industries, including electronics, optics, and decorative coatings. Customized cobalt target options are also available to meet specific requirements. These variants can include cobalt alloys such as CoCr, CoNi, or CoFe or dopants like nitrogen, oxygen, or carbon to adjust film properties. Cobalt Sputtering Targets provide precise control over deposition processes, resulting in uniform thin films of excellent quality with solid adhesion and desirable characteristics. As a result, cobalt-containing targets are essential in sputtering technology, enabling the creation of advanced materials with diverse functionalities for a wide range of applications.

The primary Cobalt Sputtering Targets include Cobalt Sputtering Targets, Cobalt Alloys (including some high-entropy alloys), Cobalt Oxide Sputtering Targets, and Cobalt Compound Sputtering Targets.

Due to their unique properties, Cobalt and Cobalt-related Sputtering Targets find diverse applications across various industries. Some of the critical applications include:

1. Semiconductor Manufacturing: Cobalt Sputtering Targets are used in producing semiconductor devices such as integrated circuits (ICs), which are employed in metal deposition processes for interconnects and contacts. Cobalt’s excellent electrical conductivity and compatibility with advanced semiconductor fabrication processes make it an ideal choice for these applications.

2. Thin-Film Coatings: Cobalt and cobalt alloy sputtering targets deposit thin films onto substrates for various purposes, including corrosion resistance, wear resistance, and decorative coatings. These coatings find applications in automotive parts, consumer electronics, aerospace components, and medical devices.

3. Magnetic Storage Media: Cobalt Sputtering Targets are essential in producing magnetic storage media such as hard disk drives (HDDs). Cobalt-based thin films are used as recording layers due to their high magnetic coercivity and stability, enabling high-density data storage with reliable performance.

4. Optical Coatings: Cobalt oxide sputtering targets are utilized to deposition optical coatings for lenses, mirrors, and other optical components. These coatings can provide anti-reflective properties, enhance light transmission, or impart specific colors or optical effects to surfaces.

5. Fuel Cells and Electrochemical Devices: Cobalt-based materials are used as catalysts in fuel cells and other electrochemical devices for energy conversion and storage. Cobalt sputtering targets deposit thin catalyst layers onto electrodes, facilitating efficient electrochemical reactions.

6. Biomedical Applications: Cobalt-based thin films deposited from sputtering targets have potential applications in biomedical devices and implants. These coatings can provide biocompatibility, corrosion resistance, and other desirable properties for implants such as stents, orthopedic, and dental implants.

Overall, cobalt and cobalt-related sputtering targets enable advanced technologies and applications across a wide range of industries, from electronics and telecommunications to energy, healthcare, and beyond.

Our Cobalt Sputtering Targets are clearly labeled externally to ensure efficient identification and quality control. We take great care to prevent damage during storage or transportation.