Menu

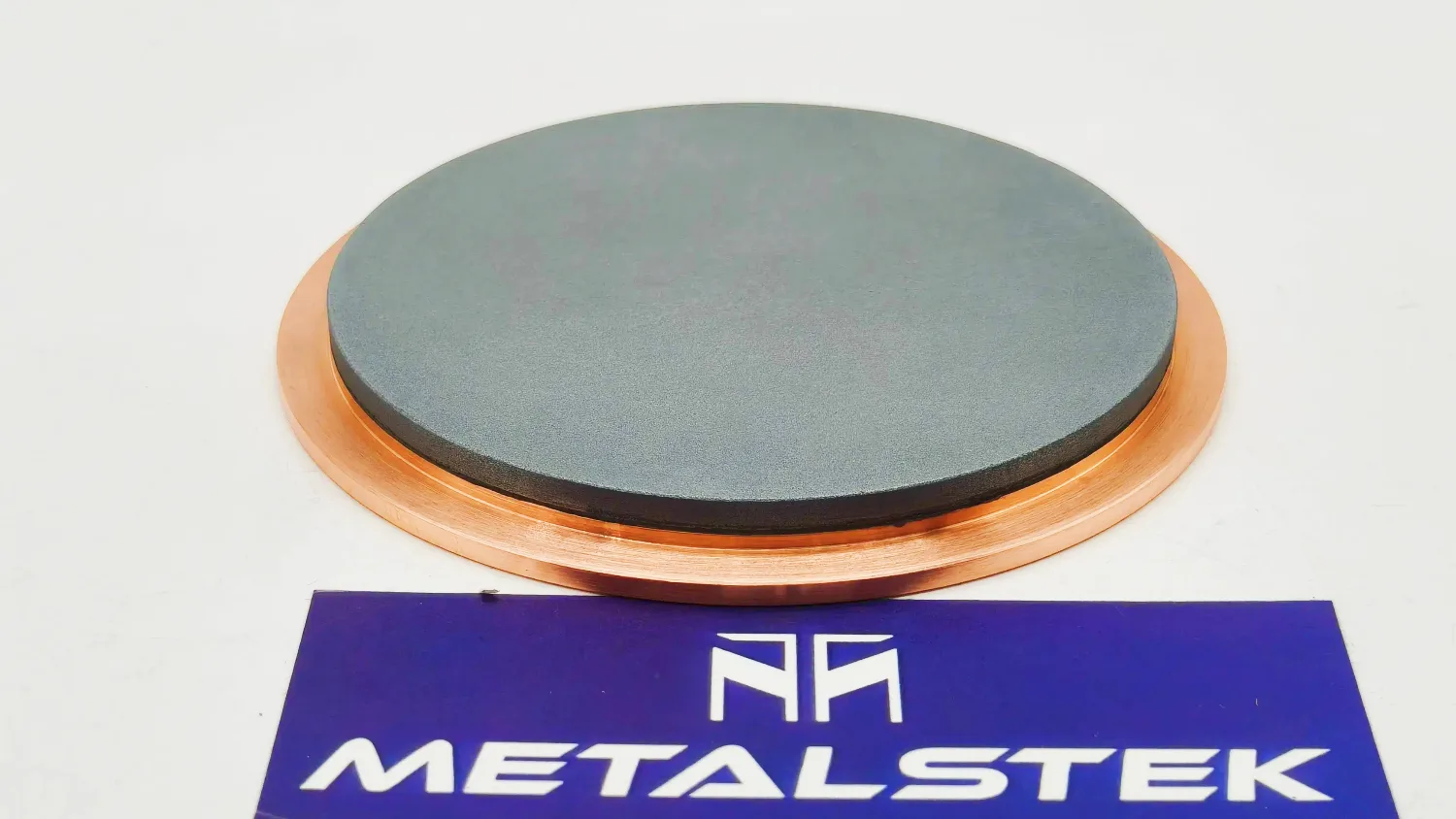

MetalsTek Engineering is a leading manufacturer and supplier of high-quality flat and rotary Molybdenum Sputtering Targets. We offer Sputtering Targets in different shapes and sizes upon request. Feel free to Get A Quote if you need any of the targets.

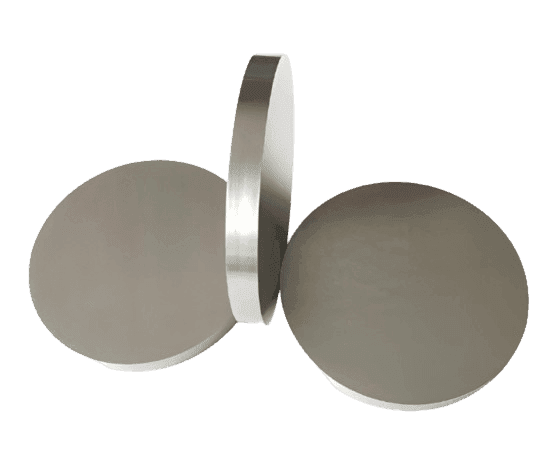

Material: Molybdenum (Mo)

Purity: 99%, 99.5%, 99.9%, 99.95%

Size Range: Disc – Dia.10~360mm * Thick 1~10mm

Planar – Thick 1~10mm * Width 20~600mm * Length 20~2,000mm

Rotary – OD 20~400mm * Length 100~300mm, Wall Thick 1~30mm

Standard Sizes: Diameter 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″, 8.0”; Thick: 0.125″, 0.250″, Can be Customized

Material: Molybdenum Carbide (Mo2C)

Purity: 99%, 99.5%, 99.9%

Shape: Disc, Bar, Rotary, Can be Customized

Size: Diameter 1.0″, 2.0″, 3.0″, 4.0″; Thick: 0.125″, 0.250″, Can be Customized

Material: Molybdenum Disilicide (MoSi2)

Purity: 99%, 99.5%, 99.9%

Shape: Disc, Bar, Rotary, Can be Customized

Size: Diameter 1.0″, 2.0″, 3.0″, 4.0″; Thick: 0.125″, 0.250″, Can be Customized

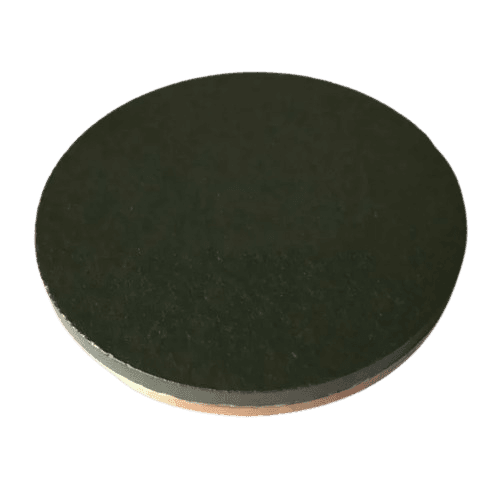

Material: Molybdenum Disulfide (MoS2)

Purity: 99.5%, 99.9%, 99.95%

Shape: Disc, Bar, Rotary, Can be Customized

Standard Sizes: Diameter 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″, 8.0”; Thick: 0.125″, 0.250″, Can be Customized

Material: Molybdenum Telluride (MoTe2)

Purity: 99.5%, 99.9%, 99.95%

Shape: Disc, Bar, Rotary, Can be Customized

Standard Sizes: Diameter 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″, 8.0”; Thick: 0.125″, 0.250″, Can be Customized

Material: Molybdenum Selenide (MoSe2)

Purity: 99.5%, 99.9%, 99.95%

Shape: Disc, Bar, Rotary, Can be Customized

Standard Sizes: Diameter 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″, 8.0”; Thick: 0.125″, 0.250″, Can be Customized

Material: Molybdenum Oxide (MoO3)

Purity: 99.5%, 99.9%, 99.95%

Shape: Disc, Bar, Rotary, Can be Customized

Size: Diameter 1.0″, 2.0″, 3.0″, 4.0″; Thick: 0.125″, 0.250″, Can be Customized

Material: Molybdenum/Rhenium (Mo/Re)

Composition: 60Mo:40Re, 50Mo:50Re

Purity: 99.95%

Shape: Disc, Bar, Rotary, Can be Customized

Size: Diameter 1.0″, 2.0″, 3.0″, 4.0″; Thick: 0.125″, 0.250″, Can be Customized

Material: Mo/Nb, Mo/Cr, MoTe2, MoSe2, Mo2B5

Purity: 99%, 99.5%, 99.9%, 99.95%, 99.99%, 99.999%

Shape: Disc, Bar, Rotary, Can be Customized

Size: Customized

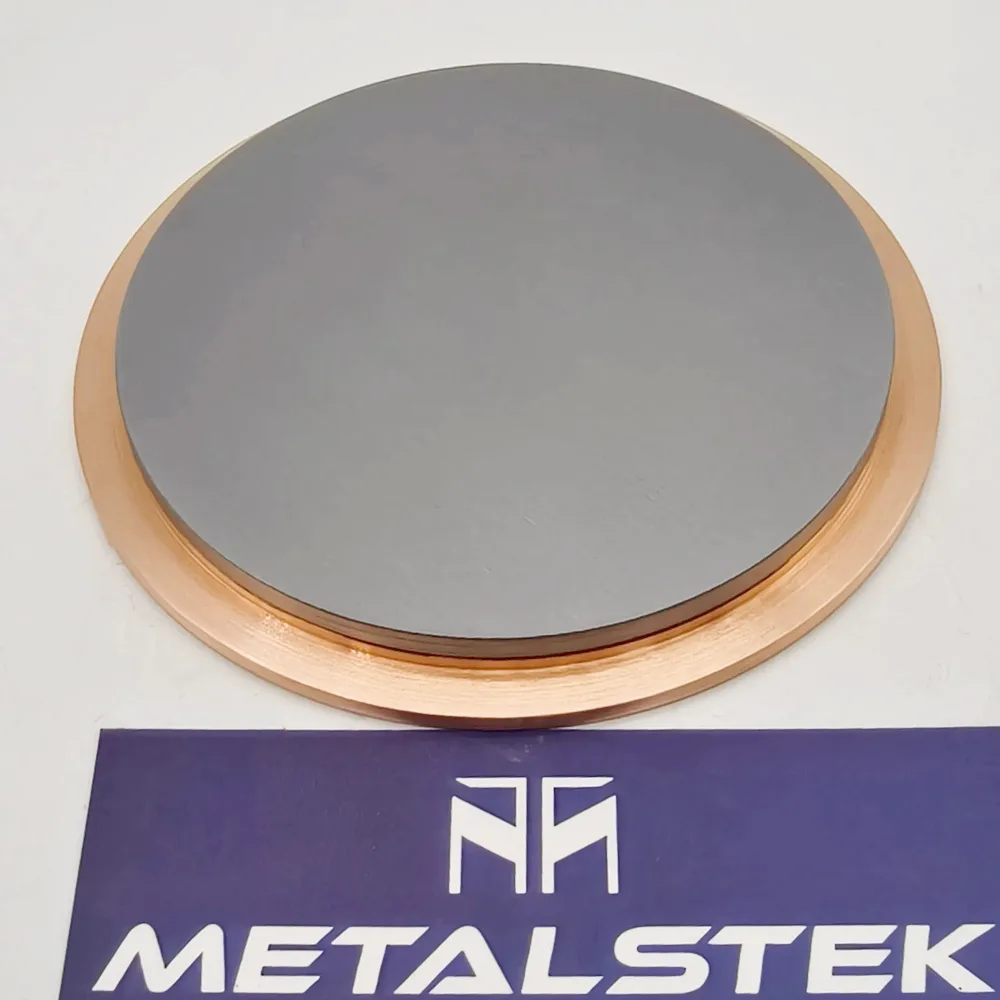

A molybdenum sputtering target is a specialized material used in physical vapor deposition (PVD), specifically sputtering. Sputtering is a technique where atoms or molecules from a solid target material are ejected and then deposited onto a substrate to form a thin film. Molybdenum sputtering targets are designed for applications in which a thin layer of molybdenum is needed on a substrate, such as in producing semiconductor devices, solar cells, and thin-film coatings.

Sputtering Target: Mo, Mo/Re, Mo/Nb, Mo/Cr, MoTe2, MoSe2, Mo2B5, Mo2C, MoO3, MoSi2, MoS2

Target Type: Disc, Planar, Rotary, Customized

Size: Customized

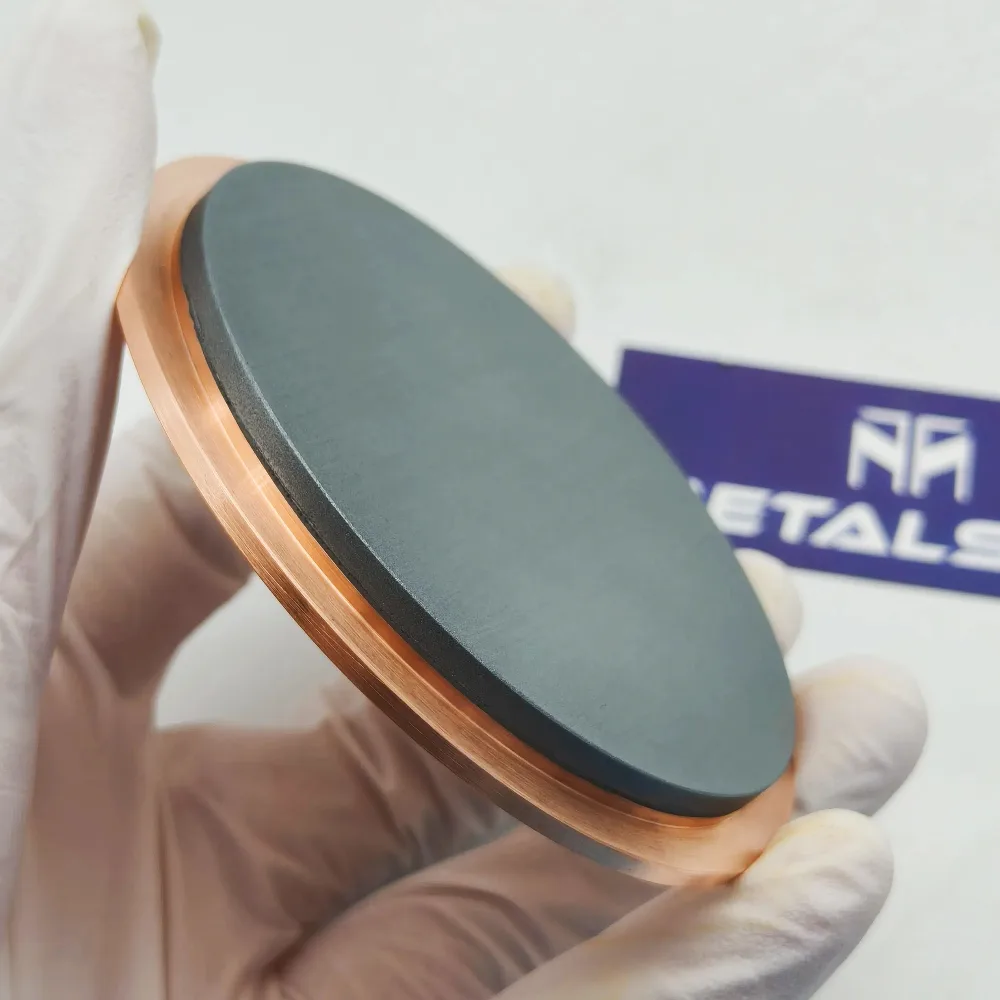

Back Bonding: Indium, Elastomer

When comparing rotatory targets with planar targets, it is evident that they offer several advantages. They contain more material, leading to greater utilization, longer production runs, and reduced system downtime, thereby increasing the throughput of the coating equipment. Additionally, higher power densities are enabled due to the even spread of heat build-up over the surface area of the target. This results in increased deposition speed and improved performance during reactive sputtering.

Applications of Molybdenum Sputtering Targets include the deposition of molybdenum thin films for:

The controlled deposition of molybdenum through sputtering targets is essential in various industries where precise and high-quality thin films are required for specific applications.

Our Molybdenum Sputtering Targets are carefully handled and packed to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.