Menu

MetalsTek Engineering, as an expert in deposition materials, can provide these forms of Titanium Evaporation Materials with the desired purity and specifications to meet the specific requirements of your deposition processes.

Material: Titanium, Ti

Purity: 99.7%~99.999%

Shape: Pellets, Granules, Wire, Powder, or Customized

Size: Dia.3*3mm, Dia.6*6mm, or Customized

| Material Type | Titanium | Z Ratio | 0.628 |

| Symbol | Ti | E-Beam | Excellent |

| Atomic Weight | 47.867 | Thermal Evaporation Techniques | Boat: W |

| Atomic Number | 22 | Crucible: TiC,Ti2-BN | |

| Color/Appearance | Silvery Metallic | E-Beam Crucible Liner Material | Fabmate®, Intermetallic |

| Thermal Conductivity | 21.9 W/m.K | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 1,067 |

| Melting Point (°C) | 1,660 | 10-6: 1,235 | |

| Coefficient of Thermal Expansion | 8.6 x 10-6/K | 10-4: 1,453 | |

| Theoretical Density (g/cc) | 4.5 | Comments | Alloys with W/Ta/Mo; evolves gas on first heating. |

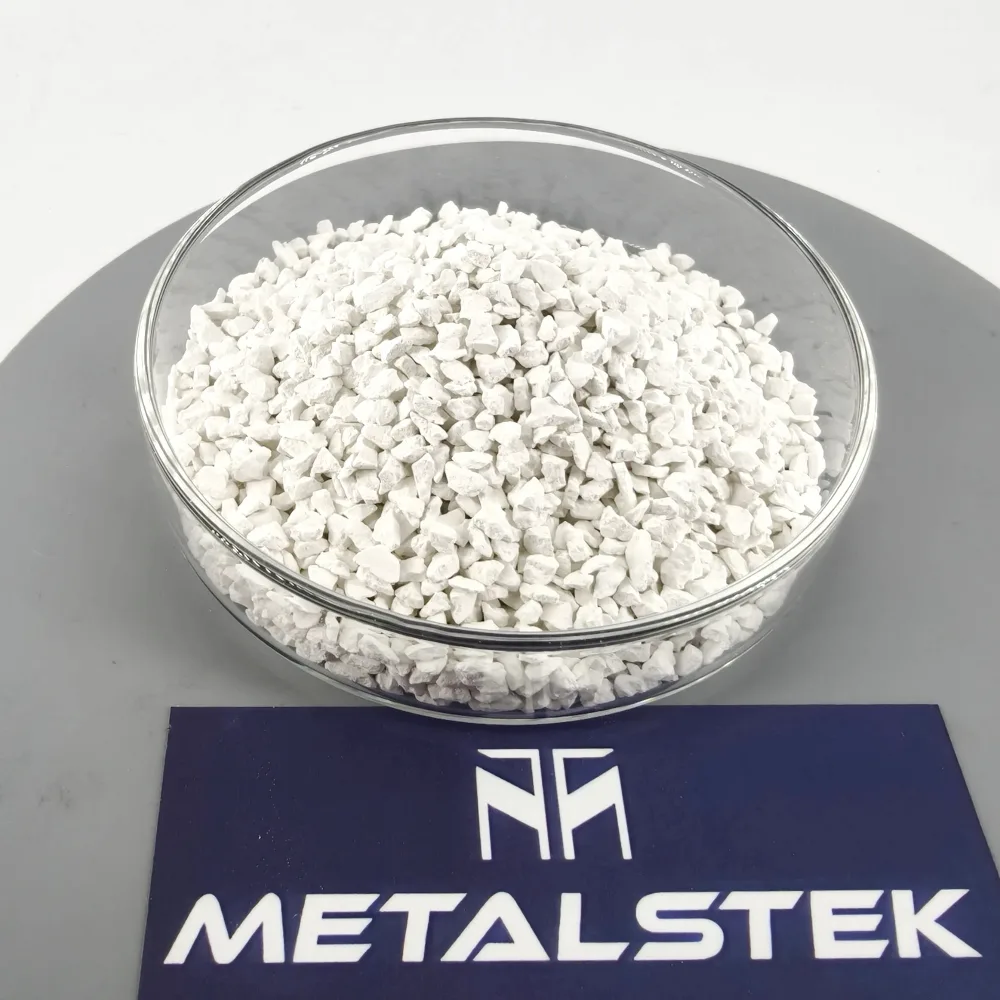

Material: Titanium (IV) Dioxide, TiO2

Purity: 99.9%~99.999%

Shape: Pellets, Pieces, Powder, or Customized

Size: Dia.3*3mm, Dia.6*6mm, or Customized

Titanium Dioxide (TiO2) Evaporation Materials play a pivotal role in thin-film deposition processes across various industries. These materials exhibit remarkable optical, electrical, and thermal properties, making them indispensable in the production of advanced electronic devices, optical coatings, and more.

| Material Type | Titanium Dioxide (TiO2) |

| Symbol | TiO2 |

| Appearance/Color | White Solid |

| Melting Point | 1,843°C (3,349°F) |

| Density | 4.23 g/cm³ |

| Purity | 99.9% – 99.999% |

| Shape | Powder/Granule/Custom-made |

Applications of Titanium Dioxide

Material: Titanium Carbide, TiC

Purity: 99.5%, 99.9%

Properties: 4.93g/cc Density, ~3,160°C M.P.

Shape: Pellets, Pieces, or Customized

Size: Customized

Material: Titanium Silicide, TiSi2

Purity: 99.5%, 99.9%

Properties: 4.02~4.10g/cc Density, ~1,4800°C M.P.

Electrical Resistivity: ~15–20 µΩ·cm

Shape: Pellets, Pieces, or Customized

Size: Customized

Material: Titanium Carbide, TiC

Purity: 99.5%, 99.9%

Properties: 4.93g/cc Density, ~3,160°C M.P.

Shape: Pellets, Pieces, or Customized

Size: Customized

Material: Titanium Nitride, TiN

Purity: 99.5%, 99.9%

Properties: 5.24g/cc Density, ~2,930°C M.P.

Shape: Pellets, Pieces, or Customized

Size: Customized

Material: Aluminum Titanium

Purity: 99.9%~99.99%, Composition Can be Customized

Shape: Pellets, Pieces, Powder, or Customized

Size: Customized

Aluminum Titanium (Al/Ti) Evaporation Materials represent a fusion of aluminum (Al) and titanium (Ti) in a specific ratio or alloy composition. These materials play a pivotal role in vacuum deposition processes, particularly in applications involving thin film coatings.

In the evaporation process, the Al/Ti mixture undergoes heating within a high-vacuum environment until it reaches its designated evaporation temperature. The resulting vaporized material then condenses onto a substrate, forming a precise and controlled thin film coating. The adjustment of the aluminum to titanium ratio enables the attainment of specific properties in the deposited thin film, including hardness, wear resistance, electrical conductivity, and corrosion resistance.

Widely employed across industries such as electronics, optics, aerospace, and automotive, Al/Ti Evaporation Materials serve as coatings for diverse components. These include semiconductor components, optical lenses, mirrors, and decorative films. Capitalizing on their distinctive combination of properties, Al/Ti films exhibit exceptional adhesion to substrates, boast good thermal stability, and offer high reflectivity for both visible light and infrared radiation.

Material: Cr/Ti, Ti/Cr, Co/Ti, Ti/Co, Mo/Ti, Ti/Mo, Ni/Ti, Ti/Ni, Ti/Al/V, Ti/W, W/Ti, V/Ti, Zr/Ti

Purity: 99%~99.999%

Shape: Pellets, Granules, Pieces, Powder, or Customized

Size: Can be Customized

Material: TiF3, TiB2, TiSe2

Purity: 99%~99.999%

Shape: Pellets, Granules, Pieces, Powder, or Customized

Size: Can be Customized

Titanium is a lustrous, silvery-white transition metal with a melting point of 1,660°C and a density of 4.5 g/cc. It is rated “excellent” for e-beam evaporation. Titanium can be evaporated via electron beam or thermal evaporation, but e-beam evaporation is preferred. It is important to note that titanium alloys with other metals can also be used as evaporation materials. Titanium Evaporation Materials are used in various thin-film deposition processes, such as electron beam (e-beam) and thermal evaporation. These materials are available in different forms, purities, sizes, and prices.

Titanium Evaporation Materials include below types: of pure Titanium (Ti), Titanium Oxide (TiO, TiO2, Ti2O3, Ti3O5), Titanium Nitride (TiN), Titanium Carbide (TiC), Titanium Fluoride (TiF3), Titanium Silicide (TiSi2), Titanium Boride (TiB2), Titanium Selenide (TiSe2), Aluminum Titanium (Al/Ti, Ti/Al), Chromium Titanium (Cr/Ti, Ti/Cr), Cobalt Titanium (Co/Ti, Ti/Co), Molybdenum Titanium (Mo/Ti, Ti/Mo), Nickel Titanium (Ni/Ti, Ti/Ni), Titanium Aluminum Vanadium (Ti/Al/V), Titanium Tungsten (Ti/W, W/Ti), Vanadium Titanium (V/Ti), Zirconium Titanium (Zr/Ti), and more.

Material Type | Titanium | Z Ratio | 0.628 |

Symbol | Ti | E-Beam | Excellent |

Atomic Weight | 47.867 | Thermal Evaporation Techniques | Boat: W |

Crucible: TiC,TiB2-BN | |||

Atomic Number | 22 | E-Beam Crucible Liner Material | FABMATE®, Intermetallic |

Color/Appearance | Silvery Metallic | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 1,067 |

10-6: 1,235 | |||

10-4: 1,453 | |||

Thermal Conductivity | 21.9 W/m.K | Comments | Alloys with W/Ta/Mo; evolves gas on first heating. |

Melting Point | 1,660 °C | ||

Coefficient of Thermal Expansion | 8.6 x 10-6/K | Suggested QCM Crystal | Alloy Crystal: 750-1002-G10**** |

Theoretical Density | 4.5 g/cc |

| Grade | TaC-1 | TaC-2 | TaC-3 |

|---|---|---|---|

| TaC(%) | ≥99.5 | >99.0 | >99.0 |

| Carbon(%) | ≥6.20 | ≥6.20 | ≥6.20 |

| Free Carbon(%) | ≤0.10 | ≤0.15 | ≤0.15 |

| Fe(%) | ≤0.05 | ≤0.1 | ≤0.20 |

| Si(%) | ≤0.008 | ≤0.01 | ≤0.020 |

| Al(%) | ≤0.005 | ≤0.005 | ≤0.01 |

| Ti(%) | ≤0.008 | ≤0.015 | ≤0.02 |

| N(%) | ≤0.025 | ≤0.05 | ≤0.05 |

| Na(%) | ≤0.003 | ≤0.005 | ≤0.02 |

| Ca(%) | ≤0.005 | ≤0.005 | ≤0.01 |

| K(%) | ≤0.003 | ≤0.005 | ≤0.01 |

| Nb(%) | ≤0.3 | ≤1.0 | ≤1.0 |

Titanium Evaporation Materials, such as titanium pellets, pieces, and powders, are widely used in various thin-film deposition processes, including semiconductor deposition, chemical vapor deposition (CVD), and physical vapor deposition (PVD). These materials are carefully handled to prevent damage during storage and are available in various forms, purities, sizes, and prices. They are used for a range of applications, including wear protection, decorative coatings, displays, and optics.

Titanium Evaporation Materials are also used in the production of high-temperature superconductors, light-emitting devices, medical imaging and therapy, lasers, and superconductors.

The choice of material depends on the specific requirements of the application, such as purity, size, and evaporation method. E-beam evaporation is the preferred method for evaporating titanium, and the materials are available in different forms and purities.

Our Titanium Evaporation Materials are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.