Menu

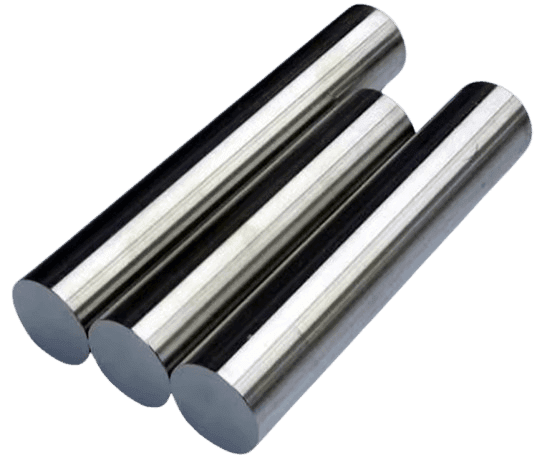

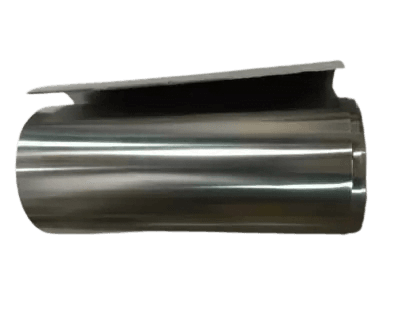

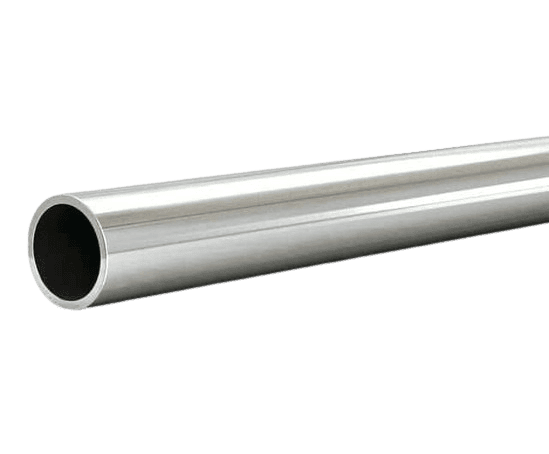

MetalsTek Engineering specializes in providing quality Tantalum Tungsten (TaW) alloy products with competitive prices and short lead times. The TaW alloy products include Square Bar, Sheet, Strip, Board, Plate, Disc, Rod, Wire, Powder, Spherical Powder, Tube, Pipe, and Sputtering Target.

Material: Tantalum Tungsten

Purity: 99.5%, 99.9%, 99.99%

Model: Ta10W (W9~11%), Ta2.5W, Ta7.5W, Spherical, Conventional, Low-Oxygen

Particle: 100 Mesh, Can be Customized

Related Products: Tantalum, Tungsten, Tantalum Niobium Alloy, Moly-Rhenium Alloy

Materials: R05252 (Ta-2.5W), R05255 (Ta-10W)

Standard: ASTM B392

Diameter: 4-150mm, Length: 30-3,000mm

Height: 1-20mm, Width: 10-100mm, Length: 30-3,000mm

Materials: R05252 (Ta-2.5W), R05255 (Ta-10W), Or Customized

Standard: ASTM B708-98

Thickness: 5-100mm

Width: 30-1,000mm

Length: 30-3,000mm

Materials: R05252 (Ta-2.5W), R05255 (Ta-10W)

Standard: ASTM B708-98

Thickness: 0.07-20mm

Width: 30-1,000mm

Length: 30-3,000mm

Materials: R05252 (Ta-2.5W), R05255 (Ta-10W)

Standard: ASTM B708-98

Thickness: 0.03-0.07 mm

Width: 30-200 mm

Length: >50 mm

Materials: R05252 (Ta-2.5W), R05255 (Ta-10W)

Standard: ASTM B493

Outer diameter: 2-120mm

Wall thickness: 0.5-5mm

Length: 200-3000mm

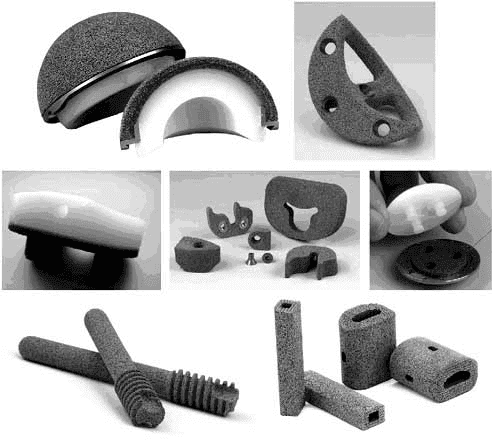

Tantalum Tungsten Alloy has excellent biocompatibility. The tantalum implant formed by 3D printing has an elastic modulus closest to that of human cartilage tissue and is the ideal orthopedic implant material. Tantalum Tungsten Alloy Powder has the characteristics of good fluidity, high purity, high bulk density, total density inside the particle, no hollow powder, etc. It is widely used in the field of biomedicine.

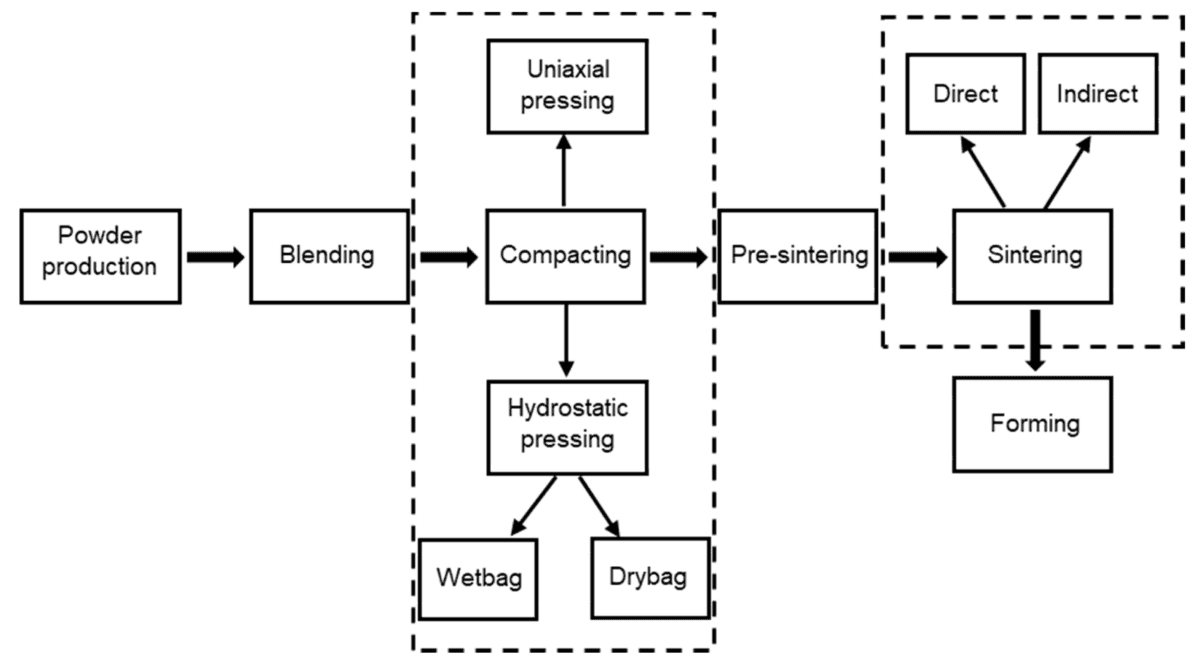

Tantalum-tungsten alloy (TaW) stands out for its well-balanced mechanical properties and exceptional corrosion resistance. This high-strength metal alloy possesses a notable combination of a high melting point, tensile strength, and corrosion resistance. MetalsTek employs advanced powder metallurgy techniques to craft tantalum alloys, blending tantalum powder with alloy elements. The mixture is then placed into molds, compressed at up to 2000 bars, and sintered. Ta10W alloy (90% tantalum, 10% tungsten) is widespread among our alloys. Particularly well-suited for applications in the chemical instrumentation construction field, Ta10W alloy finds optimal use in heat exchangers and heating components.

In addition to alloys, MetalsTek offers high-purity Spherical TaW Powder (TA2.5W), Tantalum Tungsten (Ta2.5W) Alloy Powder, Spherical TaW Powder (TA7.5W), and Spherical TaW Powder (TA10W).

| Chemical Composition (%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grade | Main Content | Impurities (≤%) | |||||||||||

| Ta | Nb/W | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | Remainder | —— | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.03 | 0.015 | 0.01 | 0.0015 | 0.01 |

| Ta2 | Remainder | —— | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.02 | 0.01 | 0.0015 | 0.01 |

| TaNb3 | Remainder | <3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.02 | 0.01 | 0.0015 | 0.01 |

| TaNb20 | Remainder | 17~23 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | —— | 0.02 | 0.01 | 0.0015 | 0.01 |

| Ta2.5W | Remainder | 2.0~3.0 | 0.005 | 0.005 | 0.002 | 3 | 0.01 | 0.002 | 0.04 | 0.015 | 0.01 | 0.0015 | 0.01 |

| Ta10W | Remainder | 9~11 | 0.005 | 0.005 | 0.002 | 11 | 0.01 | 0.002 | 0.04 | 0.015 | 0.01 | 0.0015 | 0.01 |

| Compositions Can be Customized | |||||||||||||

Our Tantalum Tungsten Alloy are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.

Tantalum Tungsten Alloy, the unbreakable duo that is revolutionizing the world of materials. This unique combination of elements brings together the exceptional properties of both tantalum and tungsten to create a material that is not only incredibly strong but also highly resistant to corrosion and wear. With its remarkable durability, this alloy is finding applications in a wide range of industries, from aerospace and defense to electronics and medical devices.

Tantalum, known for its resistance to acid and high melting point, is combined with tungsten, which boasts the highest melting point of any metal. The result is a material that can withstand extreme temperatures, making it ideal for high-stress applications. Its resistance to corrosion and wear further enhances its suitability for demanding environments.

In the aerospace industry, Tantalum Tungsten Alloy is being used to create lightweight yet strong components, improving fuel efficiency and performance. In electronics, it is utilized for high-power semiconductors and circuitry. Additionally, its biocompatibility makes it an excellent choice for medical implants.

Join us as we delve into the marvels of Tantalum Tungsten Alloy, exploring its properties, applications, and the promising future it holds in various industries. Discover how this unbreakable duo is shaping the world of materials and propelling technological advancements forward.

Tantalum Tungsten Alloy is a remarkable material that possesses a unique set of properties and characteristics. Tantalum, known for its resistance to acid and high melting point, is combined with tungsten, which boasts the highest melting point of any metal. The result is a material that can withstand extreme temperatures, making it ideal for high-stress applications.

One of the key properties of tantalum tungsten alloy is its exceptional strength. This alloy is incredibly strong, even at high temperatures, making it suitable for use in demanding environments. Moreover, it exhibits excellent resistance to corrosion and wear, further enhancing its durability. These properties make tantalum tungsten alloy highly desirable for a wide range of applications.

Another notable characteristic of tantalum tungsten alloy is its biocompatibility. This means that it is well-tolerated by the human body, making it an excellent choice for medical implants. The alloy’s resistance to corrosion ensures that it remains intact and safe within the body, while its strength ensures the longevity of the implant.

The aerospace industry is one of the primary beneficiaries of tantalum tungsten alloy. This alloy is used to create lightweight yet strong components for aircraft and spacecraft. The high strength-to-weight ratio of tantalum tungsten alloy allows for the production of lighter and more fuel-efficient aircraft, leading to reduced emissions and increased performance.

Additionally, the exceptional resistance to corrosion and wear of tantalum tungsten alloy makes it ideal for use in aerospace applications. The harsh conditions experienced during flight, including extreme temperatures and exposure to corrosive agents, can be effectively mitigated by the use of this alloy. This ensures the longevity and reliability of critical components, contributing to the overall safety of the aircraft.

Tantalum Tungsten Alloy is gaining popularity in the field of medical devices and implants. Its biocompatibility, combined with its strength and resistance to corrosion, makes it an excellent choice for a wide range of medical applications.

One of the key applications of tantalum tungsten alloy in the medical field is in orthopedic implants. The alloy’s strength and durability ensure that the implants can withstand the rigors of daily use, while its biocompatibility ensures that they are well-tolerated by the human body. This allows for the restoration of mobility and the improvement of the quality of life for patients.

Furthermore, tantalum tungsten alloy is also used in dental implants. The alloy’s resistance to corrosion ensures the longevity of dental implants, while its strength allows for the creation of implants that can withstand the forces exerted during chewing and biting. This makes tantalum tungsten alloy an ideal choice for dental applications, offering both durability and biocompatibility.

The electronics and telecommunications industry is another sector that benefits from the unique properties of Tantalum Tungsten Alloy. This alloy is utilized in the production of high-power semiconductors and circuitry, where its exceptional strength and resistance to corrosion are highly desirable.

Tantalum tungsten alloy is particularly well-suited for high-power applications due to its ability to withstand extreme temperatures. The alloy’s high melting point ensures that it remains stable even under the most demanding conditions, making it suitable for use in high-power electronic devices.

Moreover, the resistance to corrosion of tantalum tungsten alloy ensures the longevity and reliability of electronic components. This is particularly important in the telecommunications industry, where components are often exposed to harsh environmental conditions. The use of tantalum tungsten alloy in these applications allows for the production of high-performance and durable electronic devices.

The advantages and benefits of tantalum tungsten alloy are numerous and make it an attractive choice for a wide range of applications. The alloy’s exceptional strength and resistance to corrosion and wear ensure its durability, allowing for the production of long-lasting and reliable components.

Additionally, the high melting point of tantalum tungsten alloy enables its use in high-temperature applications, making it suitable for use in extreme environments. This opens up new possibilities for the alloy’s utilization in industries such as aerospace and defense, where components are often subjected to high temperatures and stresses.

Moreover, the biocompatibility of tantalum tungsten alloy makes it an excellent choice for medical applications. The alloy’s ability to withstand the harsh conditions within the human body, combined with its strength and durability, ensures the success of medical implants and devices.

The manufacturing and processing of tantalum tungsten alloy require specialized techniques to ensure the desired properties of the alloy are achieved. The alloy is typically produced through a powder metallurgy process, where tantalum and tungsten powders are mixed and then subjected to high temperatures and pressures.

This process allows for the formation of a uniform and homogenous alloy with the desired properties. The resulting alloy can then be further processed and shaped into the desired components through techniques such as machining, forging, and heat treatment.

The manufacturing and processing of tantalum tungsten alloy require strict control of the processing parameters to ensure the desired properties are achieved. This includes controlling the composition of the alloy, as well as the temperature and pressure conditions during processing. By carefully controlling these variables, manufacturers can produce tantalum tungsten alloy with consistent and reliable properties.

When comparing tantalum tungsten alloy with other alloys, it becomes evident that its unique combination of properties sets it apart. The alloy’s exceptional strength, high melting point, and resistance to corrosion and wear make it a superior choice for many applications.

For example, when compared to stainless steel, tantalum tungsten alloy offers significantly higher strength and resistance to corrosion. This makes it a better choice for applications that require high durability and reliability, such as aerospace and medical implants.

Similarly, when compared to other high-temperature alloys such as titanium and nickel-based alloys, tantalum tungsten alloy boasts a higher melting point. This allows for its use in applications that require the material to withstand extreme temperatures, such as aerospace and defense.

Overall, the unique combination of properties offered by tantalum tungsten alloy makes it a versatile and superior choice for a wide range of applications, setting it apart from other alloys in the market.

The future of tantalum tungsten alloy looks promising, with continued advancements and developments expected in the coming years. As industries continue to demand materials with exceptional strength, durability, and resistance to corrosion, tantalum tungsten alloy is well-positioned to meet these requirements.

In the aerospace industry, the demand for lightweight yet strong materials is expected to grow, driven by the need for increased fuel efficiency and reduced emissions. Tantalum tungsten alloy’s exceptional strength-to-weight ratio makes it an ideal choice for these applications, and its use is expected to expand further.

Similarly, in the medical field, the demand for biocompatible materials for implants is expected to rise. Tantalum tungsten alloy’s biocompatibility, combined with its strength and resistance to corrosion, makes it a desirable choice for medical applications. As the demand for medical implants increases, the use of tantalum tungsten alloy is expected to grow.

Furthermore, the electronics and telecommunications industry is predicted to continue to benefit from the unique properties of tantalum tungsten alloy. The demand for high-power electronic devices and components is expected to increase, driven by advancements in technology. The alloy’s ability to withstand extreme temperatures and resistance to corrosion make it an attractive choice for these applications.

Tantalum tungsten alloy, the unbreakable duo, is revolutionizing the world of materials. With its exceptional strength, high melting point, and resistance to corrosion and wear, this alloy is finding applications in a wide range of industries.

From aerospace and defense to electronics and medical devices, tantalum tungsten alloy is shaping the world of materials and propelling technological advancements forward. Its unique combination of properties makes it a versatile and superior choice for many applications.

As industries continue to demand materials with exceptional performance and reliability, tantalum tungsten alloy is well-positioned to meet these requirements. With its remarkable durability and promising future, this alloy is set to play a pivotal role in shaping the world of materials in the years to come.