Menu

MetalsTek Engineering supplies quality Tungsten Rhenium Alloy products in different forms: powder, wire, sheet, plate, rod, tube, thermocouple, and more.

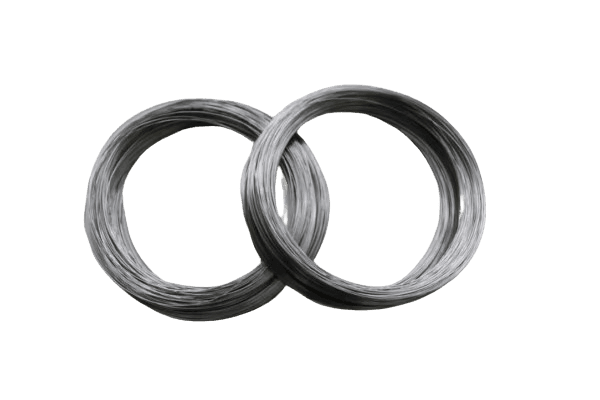

Material: Tungsten Rhenium

Composition: WRe3%, WRe5%, WRe25%, WRe26%

Appearance: Silver Metallic

Size: Diameter 0.1mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.5mm, 1.0mm

Other: Can be Customized

Material: Tungsten Rhenium

Composition: WRe3%, WRe5%, WRe25%, WRe26%

Type: Rolled, Drawn, Etched

Size: Tailored Sizes

Other: Can be Customized

Material: Tungsten Rhenium

Composition: WRe3%, WRe5%, WRe25%, WRe26%

Appearance: Silver Metallic

Size: Diameter 1~35mm

Other: Can be Customized

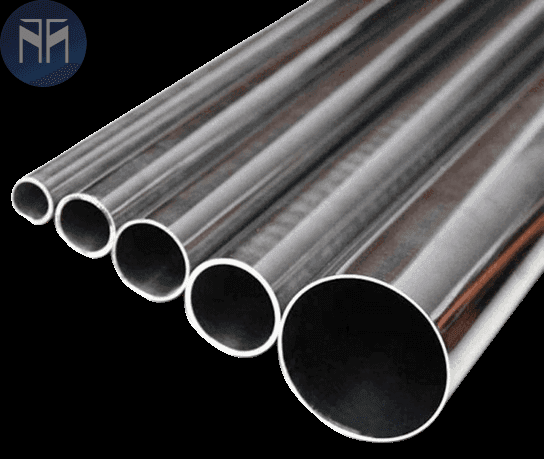

Material: Tungsten Rhenium

Composition: WRe3%, WRe5%, WRe25%, WRe26%

Appearance: Tubing

Size: Diameter 1~150mm * Length

Other: Can be Customized

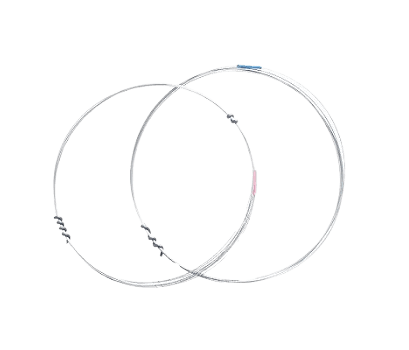

Material: Tungsten Rhenium

Composition: WRe3%, WRe5%, WRe25%, WRe26%

Appearance: Silver Metallic

Size Ranges: Thickness 0.2~1mm, Width ≤600mm, Length 10~350mm

Other: Can be Customized

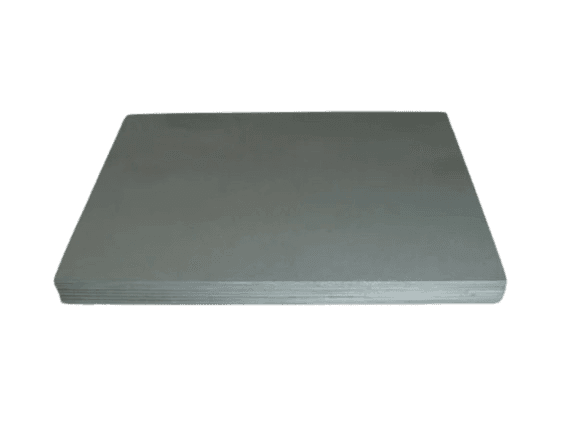

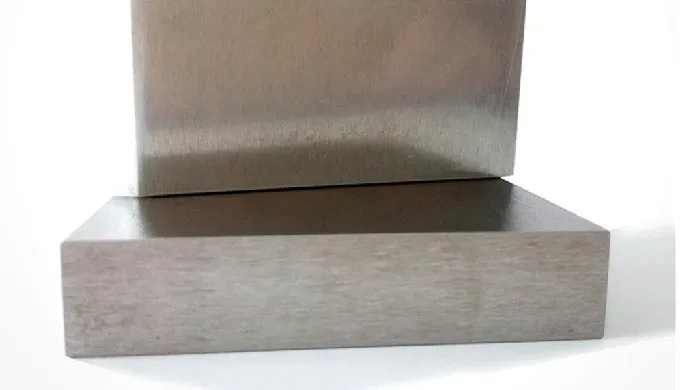

Material: Tungsten Rhenium

Composition: WRe3%, WRe5%, WRe25%, WRe26%

Appearance: Silver Metallic

Size Ranges: Thickness 1~20mm, Width ≤300mm, Length ≤300mm

Other: Can be Customized

Material: Tungsten Rhenium

Composition: WRe3%, WRe5%, WRe25%, WRe26%

Appearance: Silver Metallic

Size: Diameter 0.1mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.5mm

Other: Can be Customized

Material: Tungsten Rhenium (W-Re)

Rhenium Concentration: 3%, 5%, 10%, 25%, 26%

Purity: W-Re 99.9%, 99.99%

Density: 19.4 g/cc

Appearance: Grey Color

Particle Size: 15-53μm, 45-105μm, or Customized

Melting Point: 3,360°C

Morphology: Spherical

| Material | W | W-3Re | W-25Re | W-26Re | Re | |

| Melting Point (℃) | 3410 | 3360 | 3100 | 2950 | 3170 | |

| Density (g/cc) | 19.3 | 19.4 | 19.65 | 19.66 | 21.02 | |

| Resistivity | 20 ℃ | 5.5 | 9.7 | 27.9 | 29.6 | 19.8 |

| (uΩ.cm) | 1000 ℃ | 36.2 | 37.8 | 54.7 | 55.5 | 62.0 |

| 1500 ℃ | 52 | 53.5 | 68.5 | 70.6 | 82.0 | |

| 2000 ℃ | 66.0 | 69.0 | 82.0 | 85.0 | 150.0 | |

| Microhardness (MPa) | Machined | 3423-3923 | 3923-4325 | 5394-7845 | 5394-7845 | 4903-7845 |

| 1000 ℃ annealed | 834 | 2844-3040 | 3579-3678 | 3678-3776 | 1412 | |

| Tensile Strength (MPa) | Machined | 1950 | 3300 | 2400 | 2410 | 2256-2452 |

| 1400 ℃ annealed | 1650 | 1750 | 1950 | 1970 | ||

| 1600 ℃ annealed | 1200 | 1620 | 1810 | 1800 | ||

| 1800 ℃ annealed | 850 | 1420 | 1600 | 1620 | ||

| Elongation (%) | Machined | 1-2 | 1-2 | 2-3 | 2-3 | 1-2 |

| 1400 ℃ annealed | 1-2 | 2-3 | 15-20 | 15-20 | 20-25 | |

| 1600 ℃ annealed | 1-2 | 5-10 | 18-22 | 18-22 | 18-20 | |

| 1800 ℃ annealed | 1-2 | 10-15 | 17-19 | 17-19 | 10-15 | |

| Recrystallization Rate | 1100 | 1500 | 1800 | 1780 | 1500 | |

| Product Form | Composition | Specifications |

|---|---|---|

| Thermocouple Wire | WRe 3/25, WRe 5/26 | ø: 0.1mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.5mm |

| Sheathed Thermocouple | WRe 3/25, WRe 5/26 | Used in a vacuum, hydrogen, and inert gases with a working temperature range of 0-2,300℃ |

| Wire | WRe3%, WRe5%, WRe25%, WRe26% | ø: 0.1mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.5mm, 1.0mm |

| Rod/Bar | WRe3%, WRe5%, WRe25%, WRe26% | ø: 1mm ~ 35mm |

| Sheet/Plate | WRe3%, WRe5%, WRe25%, WRe26% | 0.2mm min * (10-350)mm * 600mm max |

| Sputtering Target | WRe3%, WRe5%, WRe25%, WRe26% | Customized Per Requirements |

WRe Alloy Tube | WRe3%, WRe5%, WRe25%, WRe26% |

Tungsten-rhenium alloy (W-Re), made from Tungsten alloy with 3%, 5%, 25%, or 26% Rhenium, about 19.7g/cc density, exhibits commendable flexibility and strength. With an elevated melting point of 3,050°C and a high recrystallization temperature of 1,900°C, this alloy finds significant applications in aerospace and temperature measurement. This alloy has gained extensive use across various industries, including thermocouples, joining processes, medical applications, aerospace technologies, and furnace and heat treatment operations.

Tungsten-rhenium, possessing a density nearly equivalent to tungsten, is commonly utilized in thermocouples and electronic devices. Its versatile properties make it valuable in various applications requiring precision temperature measurement and electronic functionality.

Tungsten-rhenium alloy finds versatile applications in various industries due to its unique properties. Some critical applications include:

In summary, tungsten-rhenium alloy’s applications span across aerospace, temperature measurement, medical devices, joining processes, high-performance furnaces, electronics, thermocouples, and the heat treatment industry, owing to its exceptional properties.

Our Tungsten Rhenium Alloy are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.

Are you in search of a material that offers unbeatable strength and durability? Look no further than tungsten rhenium alloy. This remarkable alloy is known for its exceptional properties that make it a popular choice in various industries. In this ultimate guide, we will delve deep into the world of tungsten rhenium alloy, unveiling its superior strength and durability.

With its unique composition, tungsten rhenium alloy exhibits remarkable mechanical properties that set it apart from other materials. Its high melting point, excellent resistance to corrosion, and superior tensile strength make it an ideal option for applications in extreme conditions.

Whether you’re involved in aerospace, electronics, or any other industry that demands high-performance materials, understanding the benefits and applications of tungsten rhenium alloy is essential. From rocket nozzles and electrical contacts to X-ray anodes and thermocouples, this alloy has a wide range of uses.

Join us as we explore the fascinating characteristics and applications of tungsten rhenium alloy. Discover why this remarkable material is a go-to choice for industries seeking strength, durability, and reliability.

Tungsten rhenium alloy is a unique combination of two elements – tungsten and rhenium. This alloy exhibits exceptional properties that make it highly desirable for various applications.

1. High Melting Point: One of the key characteristics of tungsten rhenium alloy is its extremely high melting point. With a melting point of over 3,000 degrees Celsius, this alloy can withstand extreme temperatures, making it suitable for applications in high-temperature environments such as rocket nozzles and furnace components.

2. Excellent Corrosion Resistance: Tungsten rhenium alloy demonstrates excellent resistance to corrosion. This property allows it to withstand harsh environments, including exposure to chemicals and corrosive substances. As a result, it is widely used in industries such as chemical processing, where corrosion resistance is crucial.

3. Superior Tensile Strength: Tungsten rhenium alloy possesses exceptional tensile strength, making it incredibly strong and durable. Its high strength-to-weight ratio makes it an ideal choice for applications that require materials to withstand heavy loads or high-pressure conditions. Aerospace and defense industries often rely on this alloy for its superior strength.

4. Good Electrical and Thermal Conductivity: Tungsten rhenium alloy exhibits good electrical and thermal conductivity, making it suitable for applications that require efficient heat transfer or electrical conductivity. It is commonly used in electrical contacts, X-ray anodes, and thermocouples.

5. Low Thermal Expansion: Another notable property of tungsten rhenium alloy is its low thermal expansion coefficient. This means that it expands and contracts minimally with changes in temperature, making it ideal for applications where dimensional stability is crucial, such as in precision instruments and tooling.

In summary, tungsten rhenium alloy is known for its high melting point, excellent corrosion resistance, superior tensile strength, good electrical and thermal conductivity, and low thermal expansion. These properties make it a versatile material for a wide range of applications.

Tungsten rhenium alloy finds extensive use in various industries due to its exceptional properties. Let’s explore some of its key applications:

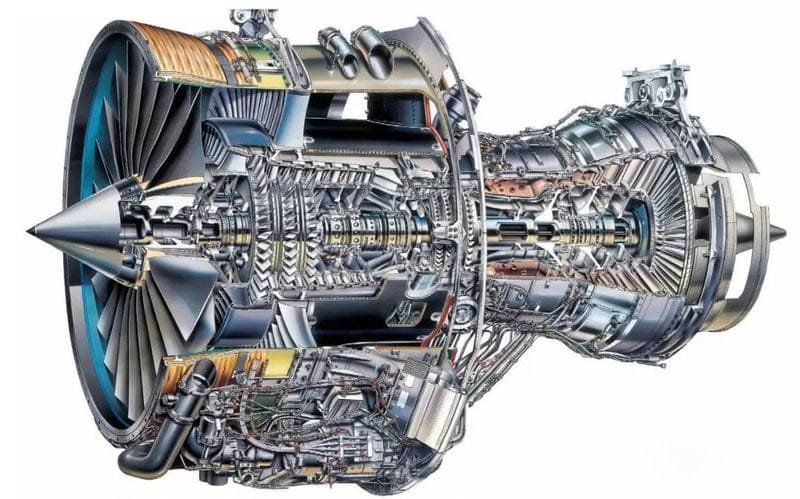

1. Aerospace Industry: The aerospace industry extensively uses tungsten rhenium alloy for its high melting point and superior strength. It is used in rocket nozzles, turbine blades, and other components that require materials capable of withstanding extreme temperatures and high stress.

2. Electronics Industry: Tungsten rhenium alloy is widely utilized in the electronics industry. Its excellent electrical conductivity makes it ideal for electrical contacts, where efficient transmission of electricity is crucial. It is also used in X-ray anodes, which require materials that can dissipate heat effectively.

3. Medical Industry: In the medical industry, tungsten rhenium alloy is utilized in various applications. It is commonly used in X-ray tubes and CT scanners due to its high melting point and good thermal conductivity. The alloy’s resistance to corrosion is especially important in medical applications where exposure to bodily fluids and chemicals is common.

4. Energy Generation: Tungsten rhenium alloy plays a vital role in energy generation. It is used in thermocouples, which convert heat energy into electrical energy, making it useful in power plants and other energy-related applications.

5. Chemical Processing: Due to its excellent corrosion resistance, tungsten rhenium alloy is widely used in chemical processing equipment. It can withstand exposure to corrosive chemicals and high temperatures, ensuring the longevity and reliability of the equipment.

These are just a few examples of the many applications of tungsten rhenium alloy. Its remarkable properties make it a preferred choice in industries where strength, durability, and reliability are paramount.

Tungsten rhenium alloy offers several advantages over other materials, making it a preferred choice in many industries. Let’s explore some of these advantages:

1. Superior Strength: Tungsten rhenium alloy possesses exceptional tensile strength, making it stronger than many other materials. Its high strength-to-weight ratio allows for the design of lightweight components without compromising on strength.

2. High Melting Point: With a melting point of over 3,000 degrees Celsius, tungsten rhenium alloy can withstand extremely high temperatures. This property makes it suitable for applications in industries where materials need to withstand extreme heat, such as aerospace and energy generation.

3. Excellent Corrosion Resistance: Tungsten rhenium alloy exhibits excellent resistance to corrosion, making it highly durable and long-lasting. It can withstand exposure to harsh chemicals and corrosive environments, ensuring the reliability of equipment and components.

4. Good Electrical and Thermal Conductivity: The alloy’s good electrical and thermal conductivity make it suitable for applications that require efficient heat transfer or electrical conductivity. It is commonly used in electrical contacts, thermocouples, and other electronic components.

5. Low Thermal Expansion: Tungsten rhenium alloy has a low thermal expansion coefficient, meaning it expands and contracts minimally with changes in temperature. This property ensures dimensional stability in applications where precise measurements and tolerances are crucial.

These advantages make tungsten rhenium alloy a superior choice over other materials in terms of strength, durability, and reliability. Its unique combination of properties sets it apart as a high-performance material for demanding applications.

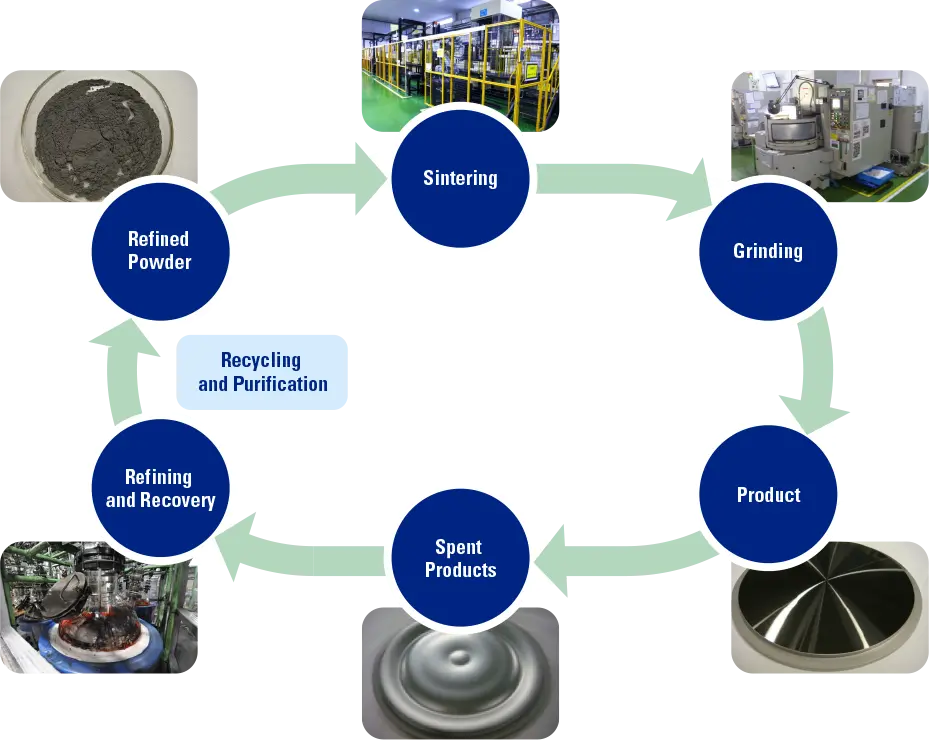

The manufacturing and production of tungsten rhenium alloy involve several processes to achieve the desired composition and properties. Let’s take a closer look at how this remarkable alloy is made:

1. Blending of Tungsten and Rhenium Powders: The first step in manufacturing tungsten rhenium alloy is the blending of tungsten and rhenium powders. The powders are carefully mixed in specific ratios to achieve the desired composition.

2. Compacting the Blended Powders: Once the powders are blended, they are compacted under high pressure to form a solid preform. This preform serves as the starting point for further processing.

3. Sintering: The preform is then subjected to a sintering process, which involves heating it to a high temperature in a controlled atmosphere. During sintering, the powders fuse together, forming a dense and uniform structure.

4. Swaging and Extrusion: After sintering, the alloy may undergo additional processes such as swaging or extrusion to further enhance its mechanical properties. These processes involve shaping the alloy into the desired form, often by applying pressure or pulling it through dies.

5. Heat Treatment: Heat treatment is often employed to optimize the mechanical properties of the alloy. This process involves subjecting the material to controlled heating and cooling cycles to achieve the desired microstructure and properties.

6. Finishing and Machining: Once the alloy has been shaped and heat-treated, it undergoes finishing and machining processes to achieve the final dimensions and surface finish required for the specific application.

The manufacturing and production of tungsten rhenium alloy require careful control of various parameters to ensure the desired composition, properties, and quality of the final product. Precise control of blending, sintering, and heat treatment processes is crucial to achieve the superior strength and durability that this alloy is known for.

When selecting tungsten rhenium alloy for a specific application, several factors need to be considered to ensure optimal performance. Here are some key factors to keep in mind:

1. Operating Conditions: Consider the operating conditions the alloy will be exposed to, including temperature, pressure, and chemical environment. Tungsten rhenium alloy’s high melting point and corrosion resistance make it suitable for extreme conditions.

2. Mechanical Requirements: Determine the mechanical requirements of the application, such as strength, ductility, and fatigue resistance. Tungsten rhenium alloy’s superior tensile strength and low thermal expansion make it an excellent choice for applications that demand high mechanical performance.

3. Electrical and Thermal Conductivity: If the application requires efficient electrical or thermal conductivity, tungsten rhenium alloy’s good electrical and thermal conductivity properties should be considered.

4. Cost: Evaluate the cost-effectiveness of using tungsten rhenium alloy for the specific application. While the alloy offers exceptional properties, it is important to consider the overall cost of production and maintenance.

5. Availability and Supply Chain: Ensure that the required quantity of tungsten rhenium alloy is readily available from reliable suppliers. Consider the supply chain and lead times to avoid delays in production or maintenance.

By considering these factors, you can make an informed decision when choosing tungsten rhenium alloy for your application, ensuring optimal performance and durability.

To maximize the lifespan and performance of tungsten rhenium alloy, proper maintenance and care are essential. Here are some guidelines to follow:

1. Regular Inspection: Regularly inspect the alloy for signs of wear, corrosion, or damage. Early identification of any issues can help prevent further damage and ensure the longevity of the alloy.

2. Cleaning: Clean the alloy regularly using appropriate cleaning methods and solutions. Avoid harsh chemicals that may damage the alloy’s surface.

3. Corrosion Protection: If the alloy is exposed to corrosive environments, consider applying protective coatings or treatments to enhance its corrosion resistance.

4. Proper Storage: Store tungsten rhenium alloy in a clean, dry environment away from corrosive substances. Ensure proper packaging and handling to prevent damage during storage or transportation.

5. Follow Manufacturer’s Guidelines: Follow the manufacturer’s guidelines for maintenance and care specific to the alloy. This may include recommendations for temperature limits, cleaning procedures, and storage conditions.

By following these maintenance and care guidelines, you can ensure the longevity and optimal performance of tungsten rhenium alloy in your application.

Tungsten rhenium alloy stands out among other alloys due to its unique combination of properties. Let’s compare it to some commonly used alloys to understand its advantages:

1. Tungsten Rhenium Alloy vs. Tungsten Carbide: While tungsten carbide offers excellent hardness, it lacks the high melting point and corrosion resistance of tungsten rhenium alloy. Tungsten rhenium alloy is better suited for applications requiring strength, durability, and resistance to extreme temperatures and corrosive environments.

2. Tungsten Rhenium Alloy vs. Titanium Alloy: Titanium alloys are known for their low density and high strength, but they have lower melting points compared to tungsten rhenium alloy. Tungsten rhenium alloy is a better choice for applications that require materials capable of withstanding higher temperatures.

3. Tungsten Rhenium Alloy vs. Stainless Steel: Stainless steel offers good corrosion resistance, but it has lower strength and melting point compared to tungsten rhenium alloy. Tungsten rhenium alloy is a superior choice for applications that demand higher strength, durability, and resistance to extreme temperatures.

By comparing tungsten rhenium alloy with other alloys, it becomes evident that its unique combination of properties makes it a superior choice for applications that require exceptional strength, durability, and resistance to extreme conditions.

Despite its many advantages, there are some common misconceptions about tungsten rhenium alloy. Let’s address a few of these misconceptions:

1. Tungsten Rhenium Alloy is Expensive: While tungsten rhenium alloy may have a higher initial cost compared to some other materials, its exceptional properties and durability can result in long-term cost savings. It is important to consider the overall cost of production, maintenance, and performance when evaluating the value of this alloy.

2. Tungsten Rhenium Alloy is Difficult to Machine: While tungsten rhenium alloy is known for its high strength, it can be successfully machined using appropriate techniques and tools. With proper machining practices, it is possible to achieve precise dimensions and surface finishes.

3. Tungsten Rhenium Alloy is Only Suitable for High-Temperature Applications: While tungsten rhenium alloy excels in high-temperature applications, it also offers many other benefits such as corrosion resistance, excellent tensile strength, and good electrical conductivity. This makes it suitable for a wide range of applications beyond just high-temperature environments.

It is important to dispel these misconceptions and understand the true value and capabilities of tungsten rhenium alloy. By doing so, industries can fully harness the strength, durability, and reliability that this remarkable material offers.

In conclusion, tungsten rhenium alloy is an exceptional material that offers unbeatable strength and durability. Its unique combination of properties, including high melting point, excellent corrosion resistance, superior tensile strength, good electrical and thermal conductivity, and low thermal expansion, make it a go-to choice for industries seeking high-performance materials.

From aerospace and electronics to medical and energy generation, tungsten rhenium alloy finds extensive use in various applications. Its remarkable mechanical properties and resistance to extreme conditions make it a preferred choice for components and equipment that require strength, durability, and reliability.

By understanding the