The Ultimate Guide to Zirconia Mortars and Pestles: From What Why to How

In the realm of laboratory equipment and material science, precision and durability are paramount. When it comes to grinding and mixing substances, zirconia mortar and pestles have emerged as indispensable tools. These instruments offer unique advantages that set them apart from traditional materials. This blog delves into the features, benefits, and applications of zirconia mortar and pestles, highlighting why they are favored in various scientific and industrial settings.

Table of Contents

Chapter 1

What is Zirconia and What is Yttrium Stabilized Zirconia (YSZ)?

Zirconia, or zirconium dioxide (ZrO₂), is a high-performance ceramic known for its exceptional hardness, resistance to wear and corrosion, and thermal stability. It is often used in advanced applications such as dental prosthetics, cutting tools, and even in the aerospace industry. Its remarkable properties make it an ideal material for use in laboratory equipment, particularly in mortar and pestles.

Yttrium Stabilized Zirconia (YSZ) is a type of zirconium dioxide (ZrO₂) that has been chemically stabilized with yttrium oxide (Y₂O₃). This stabilization process significantly enhances the properties of zirconia, making YSZ a highly durable and versatile ceramic material.

Chapter 2

Key Features of Yttrium Stabilized Zirconia (YSZ) and What's the Difference?

The Key Features of YSZ

Enhanced Stability:

- Pure zirconia exists in three phases: monoclinic, tetragonal, and cubic. At room temperature, it naturally forms in the monoclinic phase, which is less stable and prone to cracking. Adding yttrium oxide stabilizes the tetragonal and cubic phases at room temperature, preventing the transformation to the monoclinic phase and improving mechanical stability and cracking resistance.

Superior Mechanical Properties:

- YSZ exhibits excellent toughness, strength, and hardness. Its ability to resist cracking and mechanical stress makes it ideal for highly durable applications.

High Fracture Toughness:

- YSZ has a high fracture toughness, meaning it can absorb significant energy before fracturing. This property makes it resistant to wear and impact, extending its lifespan in demanding applications.

Thermal Stability:

- YSZ is highly resistant to thermal shocks and stable at elevated temperatures. This makes it suitable for high-temperature applications such as thermal barrier coatings in jet engines and other aerospace components.

Chemical Inertness:

- YSZ is chemically inert and corrosion-resistant like pure zirconia, making it ideal for use in aggressive chemical environments.

Ionic Conductivity:

- YSZ is known for its excellent ionic conductivity, particularly at high temperatures. This property makes it valuable in applications like solid oxide fuel cells (SOFCs) and oxygen sensors.

Differences Between Pure Zirconia and Yttrium Stabilized Zirconia

Phase Stability:

- Pure Zirconia: Tends to revert to the monoclinic phase at room temperature, which can lead to volume changes and cracking.

- YSZ: Stabilized in the tetragonal or cubic phase at room temperature, preventing the phase transition and improving mechanical properties.

Mechanical Strength:

- Pure Zirconia: While strong, it is more prone to cracking under stress due to phase transformations.

- YSZ: Offers superior strength and toughness, with higher resistance to cracking and mechanical failure.

Thermal Properties:

- Pure Zirconia has good thermal properties but is less stable under extreme temperatures due to phase changes.

- YSZ: Exhibits enhanced thermal stability, making it better suited for high-temperature applications.

Applications:

- Pure Zirconia: Used in various applications but may be limited in high-stress or high-temperature environments.

- YSZ: Preferred in applications requiring high mechanical strength, thermal stability, and ionic conductivity, such as dental implants, fuel cells, and thermal barrier coatings.

Cost:

- Pure Zirconia: Generally less expensive due to the absence of yttrium oxide.

- YSZ: More expensive because of the added yttrium oxide and the additional processing required for stabilization, but it offers better performance in critical applications.

Chapter 3

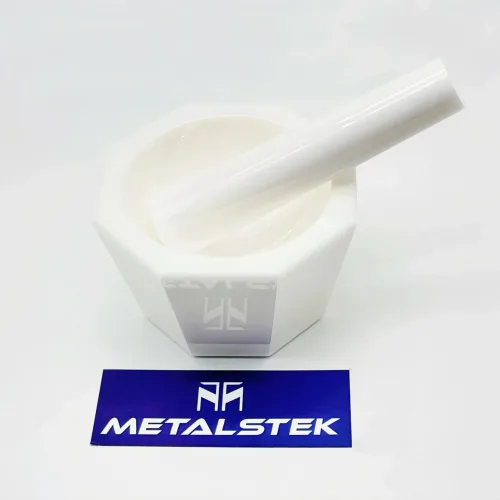

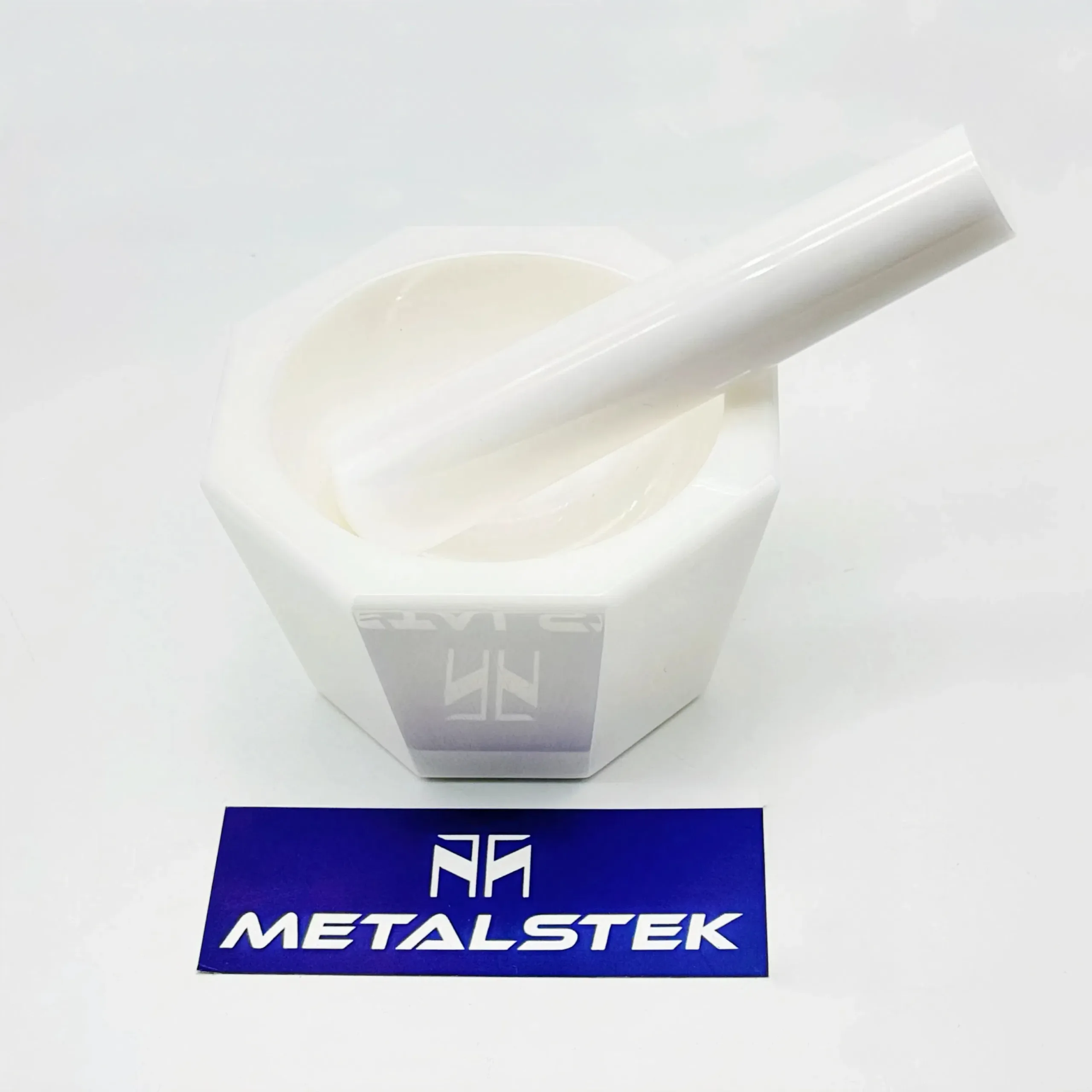

The Composition of Zirconia Mortar and Pestle

A zirconia mortar and pestle set typically comprises:

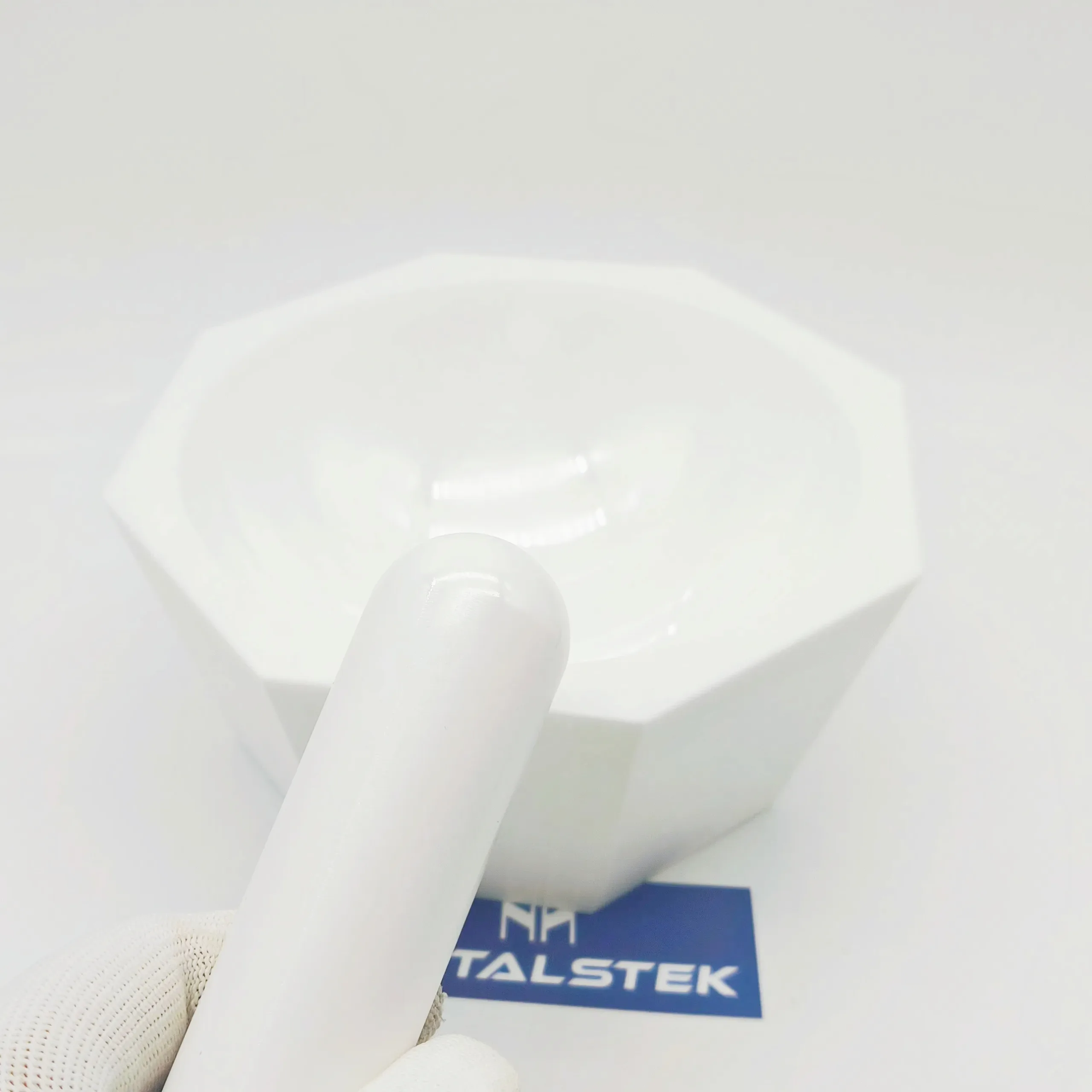

- Mortar: A bowl-shaped vessel used to hold and grind substances. Made from pure zirconia or a zirconia-based composite, it offers a smooth, non-reactive surface for effective grinding.

- Pestle: A club-shaped tool used to crush and mix materials within the mortar. Like the mortar, it is made from zirconia, ensuring durability and consistency in performance.

Chapter 4

The Advantages: Why Zirconia is the One for Mortar and Pestle?

Exceptional Hardness and Durability:

- Zirconia’s hardness ensures that the mortar and pestle can handle challenging and abrasive materials without wearing down. This durability extends the equipment’s lifespan, making it a cost-effective choice in the long run.

Chemical Inertness:

- Zirconia is chemically inert, meaning it does not react with most substances. This property is crucial when grinding reactive or sensitive materials, ensuring the integrity of the sample and preventing contamination.

High Resistance to Wear and Tear:

- Zirconia’s wear resistance means that mortars and pestles will maintain their effectiveness even after extended use. This is particularly important in high-throughput laboratories, where equipment undergoes frequent use.

Thermal Stability:

- Zirconia can withstand high temperatures without deforming or breaking. This makes zirconia mortar and pestles suitable for applications that involve heat-sensitive materials or processes.

Smooth Grinding Surface:

- The smooth surface of zirconia mortar and pestles ensures a uniform grinding action, essential for achieving consistent results in laboratory experiments and industrial processes.

Chapter 5

Applications of Zirconia Mortar and Pestle: What are the Uses?

Material Science:

- In material science, zirconia mortars and pestles prepare samples for analysis. Their durability and chemical resistance make them ideal for grinding ceramics, metals, and other hard materials.

Pharmaceuticals:

- These tools are employed in pharmaceutical laboratories to grind and mix drugs and compounds. Zirconia’s inert nature ensures that there is no contamination, which is critical for drug formulation and quality control.

Chemistry:

- Chemists use zirconia mortar and pestles for various reactions and synthesis processes. The equipment is perfect for grinding reactants and intermediates, providing a stable and non-reactive surface.

Cosmetics:

- Zirconia mortar and pestles mill pigments and other ingredients in the cosmetics industry. Their smooth surface ensures that the final product has a consistent texture and quality.

Environmental Testing:

- Zirconia mortar and pestles are used for environmental testing to prepare soil, water, and air samples. Their resistance to contamination makes them suitable for analyzing trace elements and pollutants.

Chapter 6

Considerations When Purchasing Zirconia Mortar and Pestle

When selecting zirconia mortar and pestles for your laboratory or industrial needs, consider the following factors to ensure you make an informed decision:

Size and Capacity: Mortar and pestle sets come in various sizes. Choose a size that fits your sample quantities and the scale of your experiments. Larger mortars are suitable for bulk processing, while smaller ones are ideal for precise tasks.

Design and Ergonomics: The mortar and pestle’s design should align with your usage requirements. Ergonomic designs can reduce strain during use and improve efficiency. Look for features such as comfortable handles and non-slip bases.

Surface Texture: The surface texture of the mortar and pestle affects the grinding efficiency. A smooth surface is ideal for fine powders, while a rougher surface may be better for coarser materials. Ensure that the surface texture meets your specific needs.

Chemical Compatibility: Verify that the zirconia material is compatible with the substances you will be grinding. While zirconia is generally inert, certain materials may have specific requirements.

Budget and Cost-Effectiveness: While zirconia mortar and pestles can be more expensive than other materials, their durability and performance can justify the investment. Compare prices and consider the long-term benefits and cost-effectiveness of the equipment.

Brand and Quality: Opt for reputable brands known for their high-quality zirconia products. Quality assurance and manufacturer support are essential factors to consider when purchasing.

Maintenance Requirements: Consider the ease of cleaning and maintaining the mortar and pestle. Zirconia equipment is generally low-maintenance, but proper care instructions are important to ensure longevity.

Supplier and Warranty: Purchase from reliable suppliers who offer warranties and customer support. A warranty can provide peace of mind and protect your investment.

Chapter 7

Care and Maintenance

To ensure the longevity and optimal performance of zirconia mortar and pestles, follow these care and maintenance tips:

- Cleaning: Clean the mortar and pestle thoroughly with distilled water after use. Avoid using abrasive cleaners that could damage the surface.

- Drying: Ensure the equipment is arid before storing it to prevent any potential reactions with residual moisture.

- Inspection: Regularly inspect the mortar and pestle for any signs of wear or damage. Replace any components if they become compromised.

Chapter 7

MetalsTek: Your Trusted Partner for Zirconia Mortar and Pestle

Zirconia mortar and pestles are a premium choice for grinding and mixing in scientific and industrial applications. Their exceptional hardness, chemical inertness, and thermal stability make them invaluable tools in various fields, from material science to pharmaceuticals. Investing in zirconia mortar and pestles, laboratories, and industries can achieve greater precision, durability, and consistency in their processes.

When purchasing these tools, carefully considering size, design, chemical compatibility, and other factors will ensure you select the best equipment. Their superior performance and long-term benefits make zirconia mortar and pestle a worthwhile addition to any lab or production facility.

At MetalsTek, we take great pride in providing top-notch Zirconia mortar and pestle that meet the demanding requirements of today’s industries. Our dedication to quality and our capability to tailor targets to precise sizes and compositions positions us as the go-to choice for businesses looking to push boundaries and achieve greatness.