Chromium Carbide is a versatile and incredibly valuable compound used in a wide range of industries, from manufacturing to engineering. In this comprehensive guide, we will dive deep into the world of chromium carbide, exploring its properties, applications, and benefits. With its exceptional hardness, toughness, and resistance to wear and corrosion, chromium carbide has become a go-to material for protecting surfaces exposed to extreme conditions. From industrial machinery and mining equipment to cutting tools and wear-resistant applications, chromium carbide plays a vital role in enhancing durability and extending the lifespan of components. But there’s more to chromium carbide than just its strength. In this guide, we will also explore its chemical composition, production methods, and the factors that influence its performance. We will discuss its use in different industries and provide practical tips for proper handling and application. Whether you are a professional in the field or simply interested in learning about advanced materials, this ultimate guide to chromium carbide will provide you with everything you need to know to understand this remarkable compound and its extensive applications.

Properties and Characteristics of Chromium Carbide

Chromium carbide (Cr3C2) is known for its impressive hardness, typically measured at around 19-20 GPa, which is significantly higher than that of many other materials. This hardness, combined with a melting point of approximately 1,890°C, makes chromium carbide particularly suitable for high-temperature applications. The compound is also highly resistant to wear and corrosion, providing a protective barrier that extends the life of surfaces subjected to harsh environments.

Chemically, chromium carbide is composed of chromium and carbon, forming a crystalline structure that contributes to its durability and stability. Its toughness and ability to maintain its properties at elevated temperatures make it an ideal material for demanding applications in various industries.

Hardness and Wear Resistance

Chromium carbide’s hardness makes it an excellent material for applications requiring high wear resistance. For example, in the mining industry, chromium carbide coatings are applied to equipment such as excavator buckets and conveyor screws to protect them from abrasive wear. This significantly extends the service life of the equipment, reducing downtime and maintenance costs.

Corrosion Resistance

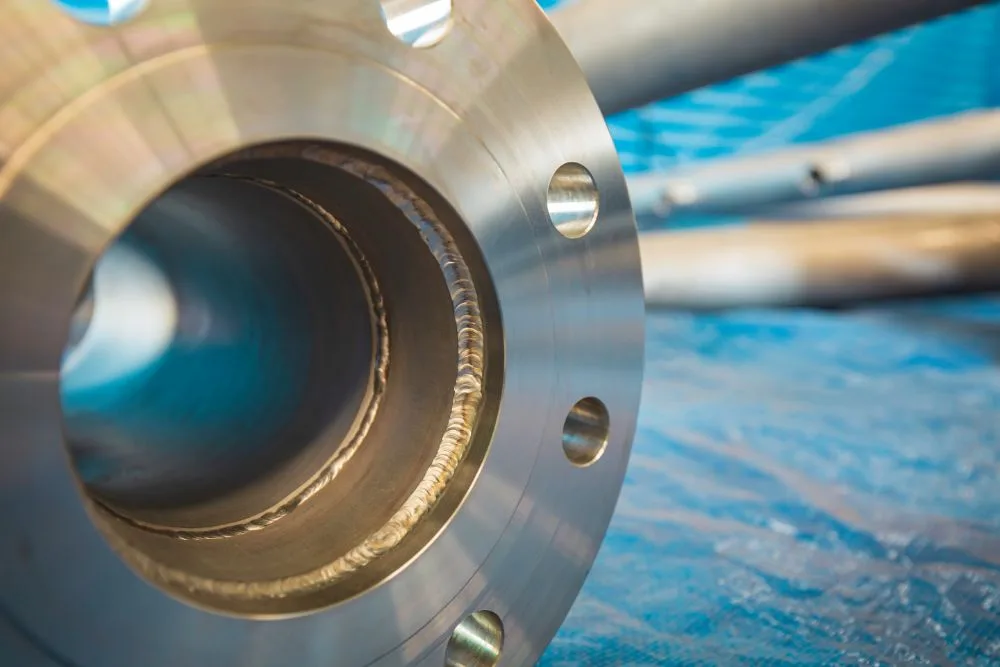

Chromium carbide also offers excellent corrosion resistance, making it suitable for use in harsh environments. In the oil and gas industry, chromium carbide coatings are used on drilling tools and pipelines to protect against corrosive substances. This ensures the integrity and longevity of the equipment, even in the presence of aggressive chemicals.

High-Temperature Stability

Chromium carbide maintains its properties at high temperatures, making it ideal for extreme heat applications. For instance, in the aerospace industry, chromium carbide coatings are used on turbine blades and other components exposed to high temperatures. This helps to prevent oxidation and thermal degradation, ensuring reliable performance under demanding conditions.

Applications of Chromium Carbide

Chromium carbide’s unique properties make it valuable in numerous applications, including:

- Industrial Machinery: Used in components that require high wear resistance, such as gears, bearings, and valve seats.

- Mining Equipment: Protects surfaces exposed to abrasive materials, enhancing the durability of mining tools and equipment.

- Cutting Tools: Enhances the lifespan and performance of cutting tools, drills, and saws. In the manufacturing industry, cutting tools such as drills, milling cutters, and saw blades are often coated with chromium carbide. This coating improves the tools’ wear resistance, allowing them to maintain sharp edges for longer periods. As a result, manufacturers can achieve higher precision and efficiency in their operations, reducing the need for frequent tool replacements.

- Wear-Resistant Coatings: Applied to surfaces to prevent wear and extend service life in extreme environments.

- Thermal Spray Coatings: Used in thermal spraying to protect surfaces exposed to high temperatures and corrosive conditions.

- Automotive Industry: Utilized in engine components and other parts that require high wear resistance and durability.

Benefits of Using Chromium Carbide

The primary benefits of using chromium carbide include:

- Exceptional Hardness: Provides superior wear resistance, reducing the need for frequent replacements and maintenance.

- High Temperature Stability: Maintains its properties even at elevated temperatures, making it ideal for high-heat applications.

- Corrosion Resistance: Protects surfaces from corrosive elements, extending the lifespan of components.

- Improved Durability: Enhances the overall durability of equipment and tools, leading to cost savings and increased efficiency.

In industrial machinery, components such as gears, bearings, and valves are often subjected to high levels of wear and tear. By applying chromium carbide coatings, these components can withstand harsh operating conditions, leading to longer service life and reduced maintenance requirements. This translates to cost savings and increased productivity for industrial operations.

Chromium Carbide Manufacturing Process

The production of chromium carbide typically involves the following steps:

- Raw Material Preparation: Chromium metal and carbon sources are prepared in the appropriate ratios.

- Mixing: The raw materials are thoroughly mixed to ensure a uniform composition.

- Sintering: The mixture is subjected to high temperatures in a controlled atmosphere, allowing the chromium and carbon to react and form chromium carbide.

- Crushing and Milling: The sintered product is crushed and milled to the desired particle size for various applications.

The SHS Method is particularly advantageous for producing chromium carbide due to its simplicity and cost-effectiveness. In this process, the reactants are mixed and ignited, resulting in a self-sustaining reaction that produces chromium carbide. This method is widely used in the production of wear-resistant coatings and composite materials.

Types of Chromium Carbide Coatings

Chromium carbide coatings can be applied using several methods, including:

- Thermal Spraying: A process where powdered chromium carbide is melted and sprayed onto a surface to form a protective coating. Thermal spraying is a popular method for applying chromium carbide coatings. In this process, the coating material is heated to a molten or semi-molten state and then sprayed onto the substrate using a high-velocity gas stream. This results in a dense, adherent coating that provides excellent wear and corrosion resistance. Thermal spraying is commonly used in the aerospace, automotive, and power generation industries.

- Welding: Chromium carbide can be applied as a hardfacing material using welding techniques to enhance wear resistance.

- Plasma Spraying: A type of thermal spraying that uses a plasma torch to melt and apply the coating material.

Maintenance and Repair of Chromium Carbide Coatings

To ensure the longevity and effectiveness of chromium carbide coatings, regular maintenance and repair are essential. This includes:

- Regular Inspections: Checking for signs of wear or damage to identify areas that may require repair.

- Reapplication: Applying additional layers of chromium carbide to worn areas to restore protection.

- Cleaning: Keeping coated surfaces clean to prevent buildup of debris that can cause abrasion.

In the mining industry, equipment such as crushers and grinding mills are often subjected to extreme wear. When the chromium carbide coating on these components shows signs of wear, it can be repaired by reapplying the coating using thermal spraying. This restores the equipment’s protective layer, ensuring continued performance and longevity.

Comparison of Chromium Carbide with Other Coating Materials

Chromium carbide is a highly valued material in various industries due to its exceptional hardness, wear resistance, and high-temperature stability. However, it is not the only material used for protective coatings. Other materials, such as tungsten carbide and hard chrome, also offer unique benefits. This section provides a detailed comparison of chromium carbide with these other coating materials, highlighting their respective advantages and applications.

Chromium Carbide vs. Tungsten Carbide

Hardness and Wear Resistance:

- Chromium Carbide: Known for its excellent hardness and wear resistance, chromium carbide is particularly effective in environments where both abrasion and corrosion are concerns. It is commonly used in applications such as mining equipment, where components are exposed to abrasive materials and corrosive environments.

- Tungsten Carbide: Tungsten carbide is even harder than chromium carbide, making it highly effective in extremely abrasive conditions. It is often used in cutting tools and wear parts that require maximum hardness and wear resistance. Tungsten carbide coatings typically have a higher Vickers hardness compared to chromium carbide, making them suitable for the most demanding wear applications.

Temperature Resistance:

- Chromium Carbide: Chromium carbide can withstand higher temperatures than tungsten carbide. This makes it suitable for high-temperature applications such as thermal spray coatings in the aerospace industry.

- Tungsten Carbide: Tungsten carbide has a lower maximum service temperature. While it excels in wear resistance, it is not as effective as chromium carbide in high-temperature environments.

Corrosion Resistance:

- Chromium Carbide: Offers superior corrosion resistance due to the formation of a passive chromium oxide layer. This makes it ideal for applications in corrosive environments, such as oil and gas pipelines and chemical processing equipment.

- Tungsten Carbide: While tungsten carbide is highly wear-resistant, its corrosion resistance is generally lower than that of chromium carbide. However, tungsten carbide coatings can be enhanced with binders such as cobalt or nickel to improve their corrosion resistance.

Chromium Carbide vs. Hard Chrome

Application Methods:

- Chromium Carbide: Typically applied using thermal spray techniques such as High-Velocity Oxygen Fuel (HVOF) spraying. This method allows for a dense, adherent coating that provides excellent wear and corrosion resistance. Thermal spray coatings can be tailored to specific applications by adjusting the composition and process parameters.

- Hard Chrome: Applied electrolytically, hard chrome provides a hard surface with good wear resistance. However, the process involves the use of hexavalent chromium, which is a hazardous substance subject to increasing regulatory restrictions. Hard chrome is often used in applications such as hydraulic cylinders and industrial rollers.

Performance Characteristics:

- Chromium Carbide: Offers a combination of high hardness, wear resistance, and corrosion resistance. It is particularly effective in high-temperature and corrosive environments, making it a versatile choice for a wide range of applications.

- Hard Chrome: Provides good wear resistance and a smooth surface finish. However, it is less effective in high-temperature environments and may not offer the same level of corrosion resistance as chromium carbide. Additionally, the environmental and health concerns associated with hexavalent chromium are significant drawbacks.

Practical Cases

Mining Industry:

- Chromium Carbide: Used to coat components such as crusher hammers and grinding mills, where both wear and corrosion resistance are critical. The high hardness and corrosion resistance of chromium carbide coatings help extend the service life of these components, reducing maintenance costs and downtime.

- Tungsten Carbide: Applied to drill bits and cutting tools that encounter extremely abrasive materials. The superior hardness of tungsten carbide ensures that these tools maintain their cutting edges for longer periods, improving efficiency and reducing the frequency of tool replacements.

Aerospace Industry:

- Chromium Carbide: Utilized in thermal spray coatings for turbine blades and other high-temperature components. The high-temperature stability and oxidation resistance of chromium carbide make it ideal for protecting components exposed to extreme heat and corrosive gases.

- Tungsten Carbide: Used in applications where maximum wear resistance is required, such as in the leading edges of turbine blades. However, its lower temperature resistance compared to chromium carbide limits its use in the hottest sections of the engine.

Oil and Gas Industry:

- Chromium Carbide: Coatings are applied to drilling tools and pipelines to protect against both wear and corrosion. The ability of chromium carbide to form a protective oxide layer enhances its performance in harsh, corrosive environments.

- Hard Chrome: Often used for hydraulic cylinders and other components that require a hard, smooth surface. While effective in many applications, the environmental concerns associated with hexavalent chromium are prompting a shift towards alternative coatings such as chromium carbide.

Safety Considerations when Working with Chromium Carbide

When handling chromium carbide, it is important to follow safety protocols to minimize health risks:

- Protective Gear: Wear appropriate protective equipment, including gloves, masks, and eye protection.

- Ventilation: Ensure adequate ventilation when working with chromium carbide powders to avoid inhalation of dust.

- Handling: Follow proper handling procedures to prevent skin contact and ingestion.

Conclusion: The Versatility and Importance of Chromium Carbide

Chromium carbide is an incredibly versatile and important material in modern industry. Its exceptional hardness, toughness, and resistance to wear and corrosion make it indispensable for protecting surfaces in harsh environments. Whether used in industrial machinery, mining equipment, or cutting tools, chromium carbide plays a crucial role in enhancing durability and extending the lifespan of components. Understanding its properties, applications, and best practices for handling and maintenance will ensure that you can fully leverage the benefits of this remarkable compound in your field.