Menu

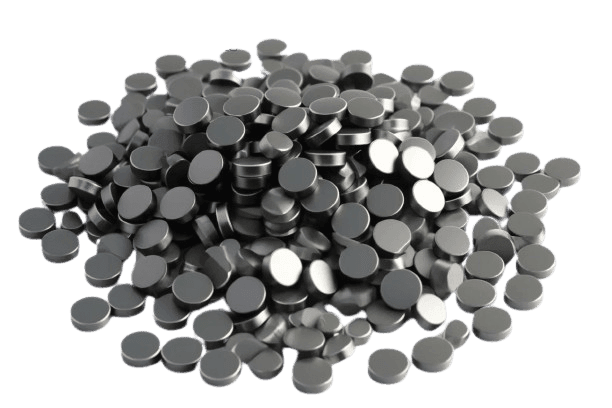

MetalsTek Engineering is a premier manufacturer and supplier of high-purity Tantalum Evaporation Materials. We offer a diverse range of evaporation materials, including powder and granule forms. We can also cater to customized requirements upon request.

Purity: Ta 99.9%, 99.95%

Density: 16.6 g/cc

Shape: Pellets, Powder, Granule, Customized

Size: ~3*3mm / 1/8″ Studs, ~6*6mm / 1/4″ Studs, Can be Customized

Applications: CVD and PVD Semiconductor Deposition, Optics Coatings

Material: Tantalum Aluminum (Ta/Al)

Purity: 99.9%, 99.95%

Shape: Pellets, Granule, Powder, or Customized

Tantalum Aluminum Evaporation Materials are specialized coatings derived from a blend of tantalum and aluminum, commonly employed in vacuum evaporation procedures. These materials find diverse applications, notably in the semiconductor industry for thin film deposition, optical coatings, and research endeavors.

The amalgamation of tantalum and aluminum in these evaporation materials offers distinctive advantages owing to their unique physical and chemical attributes. Tantalum boasts a remarkable high melting point surpassing 3,000°C, exceptional corrosion resistance, and heightened thermal stability. On the contrary, aluminum, with its lower melting point, contributes commendable electrical conductivity, enhancing the stability and adhesion of the resultant film.

The synergy between tantalum and aluminum leads to a film with enhanced properties compared to each material in isolation. The ratio of tantalum to aluminum can be fine-tuned to fulfill specific criteria, such as achieving the desired film thickness, bolstering adhesion strength, or optimizing electrical conductivity.

Material: Tantalum Molybdenum (Ta/Mo)

Purity: 99.9%, 99.95%

Shape: Pellets, Granule, Powder, or Customized

Application: Semiconductor, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications.

Material: Molybdenum Carbide

Purity: 99%~99.9%

Shape: Pellet, Granule, Customized Shape

Other: Customized Shape, Size, and Purity

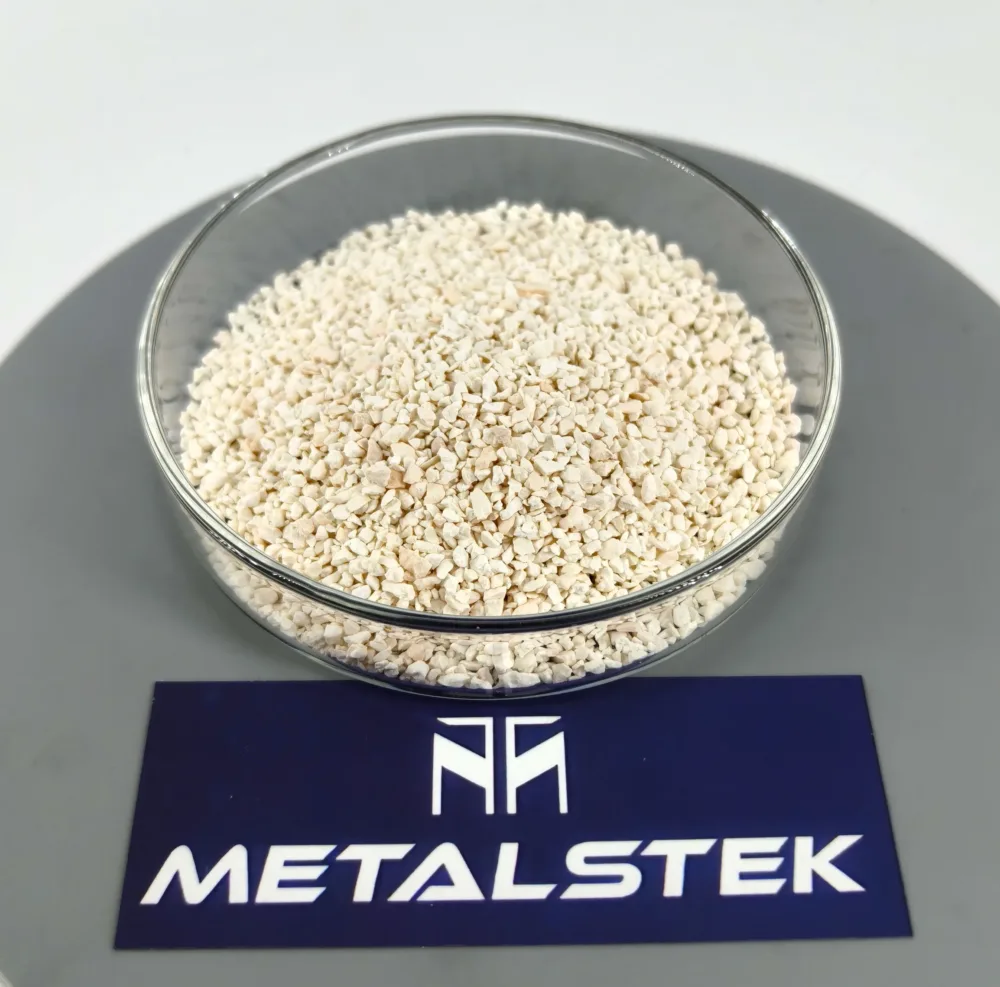

Material: Tantalum Pentoxide (Ta2O5)

Purity: Ta2O5 99.95%

Density: 8.2 g/cc

Appearance: White, Crystalline Solid

Thermal Evaporation: Boat Ta, Coil W, Basket W, Crucible VitC

Size: Dia. 8~9mm * Thick 4~5mm, or Customized

Tantalum oxide, identified by the chemical formula Ta2O5, is a crystalline solid characterized by its white appearance. It possesses a density of 8.2 g/cc, a melting point of 1,872°C, and a vapor pressure of 10-4 Torr at 1,920°C. Primarily employed in the production of capacitors, this compound is integral to various applications, including auto electronics, cell phones, and tools. Additionally, tantalum oxide is utilized in camera lens glass. Its evaporation under vacuum facilitates the creation of films for semiconductor, optoelectronic device, and fuel cell fabrication.

Material: Tantalum Nitride (TaN)

Purity: 99.5%

Density: 13.7 g/cc

Shape: Pellets, Granule, Powder, or Customized

Application: Semiconductor, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications.

Material: Tantalum Carbide (TaC)

Purity: 99.5%

Density: 143 g/cc

Melting Point: 3,852 °C / 6,966 °F; 4,125 K

Shape: Pellets, Granule, Powder, or Customized

Application: Hard Coatings, Microelectronics, Decorative Coatings, Aerospace Protections

Material: Tantalum Silicide (TaSi2)

Purity: 99.5%

Shape: Pellets, Granule, Powder, or Customized

Application: Semiconductor, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications.

Material: Tantalum Boride (TaB2)

Purity: 99.5%

Shape: Pellets, Granule, Powder, or Customized

Application: Semiconductor, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications.

Material: Tantalum Selenide (TaSe2)

Purity: 99.9% ~ 99.999%

Density: 6.7 g/cc

Melting Point: 2,000°C / 3,632°F

Shape: Pellets, Granule, Powder, or Customized

Application: Semiconductor, CVD, PVD, and used in optics for wear protection, decorative coatings, and displays.

Material: Tantalum Telluride (TaTe2)

Purity: 99.9% ~ 99.999%

Density: 9.4 g/cc

Shape: Pellets, Granule, Powder, or Customized

Application: Semiconductor, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications.

High-purity evaporation materials play a huge role in deposition processes to ensure high-quality deposited films. Tantalum(Ta), a transition metal classified on the Periodic Table, falls under refractory metals, renowned for their exceptional corrosion resistance. Possessing a melting point of 3,017°C, a density of 16.6 g/cc, and a vapor pressure of 10-4 Torr at 2,590°C, tantalum exhibits a metallic grey-blue color and shares chemical properties akin to niobium. Its non-toxic nature makes it a prime choice for surgical implants, while its application extends to the electronics industry, where it serves as a capacitor. Tantalum can be alloyed with other metals to enhance strength and durability. In vacuum evaporation, tantalum and its alloys and compounds produce semiconductors, optical coatings, magnetic storage media, and coatings with wear and corrosion resistance.

Tantalum is nearly impossible to deposit by thermal evaporation due to the high power required for the material to evaporate. E-beam evaporation or magnetron sputtering are the recommended methods for tantalum deposition. Tantalum is designated as ‘excellent’ for e-beam evaporation. Nevertheless, this process poses challenges and necessitates meticulous monitoring throughout.

| Material Type | Tantalum | Z Ratio | 0.262 |

| Symbol | Ta | E-Beam | Excellent |

| Atomic Weight | 180.94788 | E-Beam Crucible Liner Material | FABMATE®, Graphite |

| Atomic Number | 73 | ||

| Color/Appearance | Gray Blue, Metallic | Temp. (°C) for Given Vap. Press. (Torr) | 10-8: 1,960 |

| 10-6: 2,240 | |||

| 10-4: 2,590 | |||

| Thermal Conductivity | 57 W/m.K | Comments | Forms good films.

|

| Melting Point | 3,017 °C | ||

| Coefficient of Thermal Expansion | 6.3 x 10-6/K | ||

| Theoretical Density | 16.6 g/cc | Suggested QCM Crystal | Alloy Crystal: 750-1002-G10**** |

Tantalum Evaporation Material is crucial in various high-tech applications, particularly thin film deposition processes. Here are some critical applications:

The unique properties of tantalum, including its high melting point, corrosion resistance, and stability, make it a valuable material for thin film deposition in these diverse applications.

Our Tantalum Evaporation Materials are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.