Menu

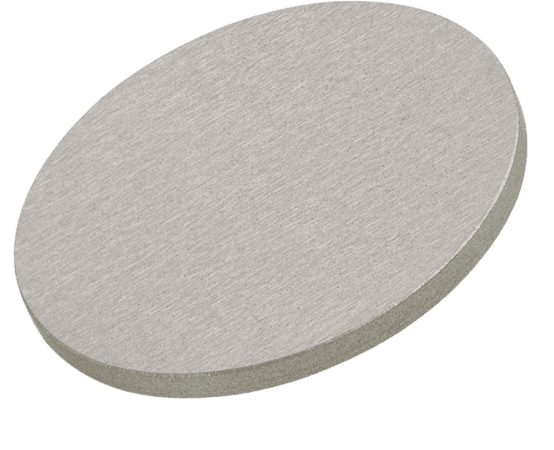

MetalsTek Engineering provides all kinds of quality Tantalum Sputtering Targets with tailored materials, shapes, sizes, and purities.

Sputtering Target: Ta, TaC, TaN, Ta2O5, TaSi2

Target Type: Disc, Planar, Rotary, Customized

Size: Customized

Back Bonding: Indium, Elastomer

Material: Tantalum (Ta-1, Ta-2, Ta-3)

Purity: Ta 99.95%, 99.99%, 99.999%

Standard: ASTM B708 (Flatness 0.1%, Roughness 0.8~1.6um)

Size Range: Disc – Diameter 1”~30” * Thick 0.125”/0.25”

Rectangular – Thick3~20mm * Width 20~500mm * Length 20~1,000mm

| Grade | Ta≥% | Chemical Composition, Max (ppm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Si | Mo | W | Ti | Cr | Nb | Ni | O | C | H | N | ||

| Ta1 | 99.995 | 1 | 0.08 | 10 | 20 | 0.8 | 0.5 | 20 | 0.1 | 100 | 50 | 15 | 50 |

| Ta2 | 99.99 | 3 | 10 | 10 | 50 | 2 | 10 | 50 | 2 | 120 | 80 | 20 | 80 |

| Ta3 | 99.95 | 10 | 20 | 50 | 100 | 10 | 20 | 300 | 10 | 150 | 100 | 30 | 100 |

Material: Tantalum Carbide, TaC

Purity: 99.5%

Melting Point: 3,880°C

Standard Sizes: Diameter 1”, 2”, 3”, 4”, 6”, 8”; Thick 0.125”, 0.25”; or Customized

Material: Tantalum Nitride, TaN

Purity: 99.5%

Sputter: RF, RF-R

Melting Point: 3,360°C

Standard Sizes: Diameter 1”, 2”, 3”, 4” ; Thick 0.125”, 0.25”; or Customized

Material: Tantalum Pentoxide, Ta2O5

Purity: 99.99%

Sputter: RF, RF-R

Melting Point: 1,872°C

Standard Sizes: Diameter 1”, 2”, 3”, 4” ; Thick 0.125”, 0.25”; or Customized

Material: Tantalum Silicide, TaSi2

Purity: 99.5%

Bonding Available: Indium

Standard Sizes: Diameter 1”, 2”, 3”, 4” ; Thick 0.125”, 0.25”; or Customized

Tantalum Sputtering Targets are used in thin film deposition, where a thin layer of tantalum is deposited onto a solid substrate by the controlled removal of material from the target. It is typically used to deposit microscopic thin tantalum layers on silicon wafers, enabling the manufacturing of next-generation semiconductor logic chips, including DRAM and 3D-NAND memory chips. Tantalum is a dark blue-gray, heavy, malleable, and hard metal with high corrosion resistance.

Tantalum Sputtering Targets include disc type, rectangular type, and rotary type.

When comparing rotatory targets with planar targets, it is evident that they offer several advantages. They contain more material, leading to greater utilization, longer production runs, and reduced system downtime, thereby increasing the throughput of the coating equipment. Additionally, higher power densities are enabled due to the even spread of heat build-up over the surface area of the target. This results in increased deposition speed and improved performance during reactive sputtering.

Some key aspects and applications of Tantalum Sputtering Targets:

Tantalum’s excellent thermal and chemical stability, along with its ability to form adherent and high-quality thin films, makes it a valuable material in the sputtering process for a range of applications.

Our Tantalum Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.