Menu

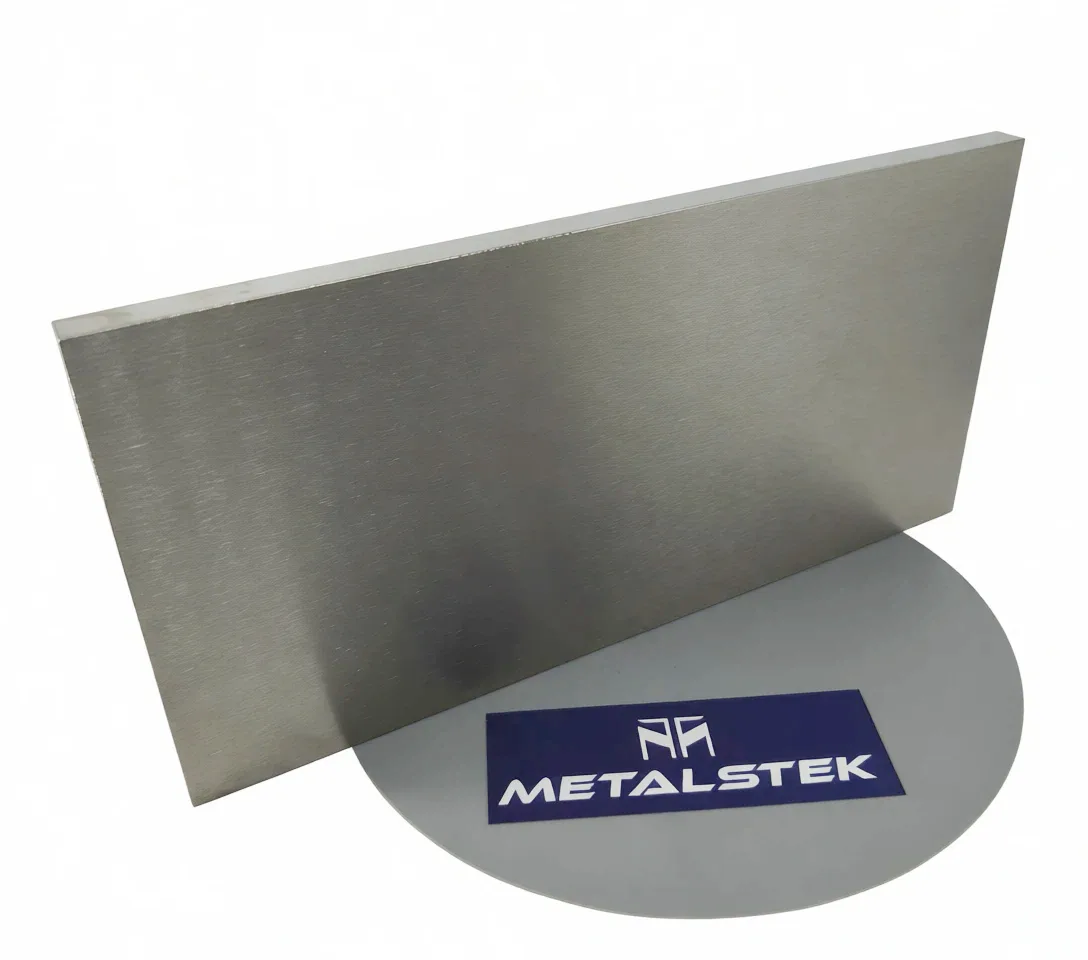

MetalsTek Engineering is a leading provider of high-quality Zirconium Sputtering Targets. Our products are tailored to meet the demanding requirements of the semiconductor, display, and optical industries—partner with MetalsTek Engineering for cutting-edge sputtering solutions that drive innovation and excellence in your applications.

Material: Zirconium, Zr

Purity: 99%, 99.9%, 99.99%

Form: Disc, Plate, Column, Stepped, Planar, Rotatory, or Customized

Size Range: Diameter 20~205mm / Dia. 1”~8”, Thick 3.175mm, 6.35mm / 0.125” and 0.25”

Zirconium, a transition metal, boasts a density of 6.49 g/cc, a melting point of 1,852°C, and a vapor pressure of 10-4 Torr at 1,987°C. Its silvery-white appearance and exceptional corrosion resistance make it highly sought after by the chemical industry. Zirconium finds extensive use in surgical appliances, superconductive magnets, and the cladding of nuclear reactors. It also serves as an alloying agent for steel and its compound, zirconia, is a popular diamond substitute in jewelry. Zirconium and its compounds are evaporated under vacuum for optical coatings, semiconductors, and data storage devices.

Both Zirconium and Hafnium can be applied in nuclear industries. However, they have different properties in neutron capture. Although they have a lot of similar properties, they need to be separated using the liquid extraction method or distillation of molten salt. We provide two grades of high purity zirconium targets: low hafnium (250ppm, or 0.025%) and high hafnium.

| Al | 48 | In | <0.05 | Re | <0.05 |

|---|---|---|---|---|---|

| As | <0.05 | Ir | <0.05 | Rh | <0.5 |

| Au | <0.05 | K | 0.25 | S | 16 |

| B | 0.07 | La | <0.013 | Sb | <0.5 |

| Bi | 0.28 | Mg | 0.09 | Sc | 0.6 |

| Br | 0.039 | Mn | 0.2 | Se | <0.05 |

| Ca | 0.33 | Mo | 3.7 | Si | 35 |

| Ce | 0.021 | Na | 0.3 | Sm | <0.05 |

| Cl | 1.6 | Nb | 1.7 | Sn | 16 |

| Co | 0.032 | Nd | <0.05 | Sr | 0.009 |

| Cr | 3.4 | Ni | 3.3 | Ta | 0.66 |

| Cu | 0.16 | Os | <0.05 | Te | <0.5 |

| F | 1.7 | P | 0.35 | Ti | 36 |

| Fe | 51 | Pb | 0.96 | U | 1.1 |

| Ga | 0.1 | Pd | <5 | V | 0.13 |

| Ge | <0.05 | Pr | 0.036 | W | 1.3 |

| I | <0.5 | Pt | <0.05 | Zn | 0.28 |

Material: Zirconia, ZrO2

Purity: 99.9%, 99.95%, 99.99%

Form: Disc, Plate, Column, Stepped, Planar, Rotatory, or Customized

Size Range: Diameter 20~205mm / Dia. 1”~8”, Thick 3.175mm, 6.35mm / 0.125” and 0.25”

Zirconia, a versatile material, is primarily used in the production of hard ceramics, notably in dentistry. Its applications extend to serving as a protective coating on particles of titanium dioxide pigments, a refractory material, a thin film coating material, and in insulation, fuel cells, abrasives, and enamels. Zirconia sputtering targets are employed for thin film deposition, particularly in fuel cell, decoration, semiconductor, display, LED, and photovoltaic devices, as well as glass coating.

Stabilized zirconia is utilized in oxygen sensors and fuel cell membranes due to its high ionic conductivity and low electronic conductivity, making it a valuable electro ceramic. Zirconium dioxide is also used as the solid electrolyte in electrochromic devices. Additionally, zirconia serves as a precursor to the electro ceramic lead zirconate titanate (PZT), a high-K dielectric found in various components.

Model: Partially Stabilized ~5% Y2O3, Fully Stabilized 8%mol Y2O3

Purity: 99.9%

Form: Disc, Plate, Column, Stepped, Planar, Rotatory, or Customized

Size Range: Diameter 20~205mm / Dia. 1”~8”, Thick 3.175mm, 6.35mm / 0.125” and 0.25”

Material: Zirconium Carbide, ZrC

Purity: 99.5%

Form: Disc, Plate, Column, Stepped, Planar, Rotatory, or Customized

Size Range: Diameter 20~205mm / Dia. 1”~8”, Thick 3.175mm, 6.35mm / 0.125” and 0.25”

Other: Indium Bonding Recommended

Material: Zirconium Nitride, ZrN

Properties: 99.5% Purity, 7.09g/cc Density, 2,980°C M.P

Form: Disc, Plate, Column, Stepped, Planar, Rotatory, or Customized

Size Range: Diameter 20~205mm / Dia. 1”~8”, Thick 3.175mm, 6.35mm / 0.125” and 0.25”

Other: Indium Bonding Recommended

Purity: Customized

Shape: Disc, Plate, Column, Stepped, Planar, Rotatory, or Customized

Size: Tailored Size

Materials: Ti/Zr, Zr/Y, Zr/W, Zr/Ti, Ni/Zr, Zr/Al, Zr/Cu, PST, Co/Nb/Zr, ZrB2, ZrSi2, ZrF4, LLZO, BZCY, ZrO2/CaO, LiZrOx, PbZrO3, CaZrO3, Gd2Zr2O7, ZrO2/Y2O3, SrZrO3, BaZrO3, HfO2/Y2O3, PbZrTiO3, and More

Other: Contact to Customize Your Sputtering Targets

Zirconium Sputtering Targets are essential in various cutting-edge applications, including semiconductors, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications. These targets are manufactured from zirconium sponge and crystal bars. They are utilized in additive manufacturing, thermal spraying coatings, hot isostatic pressing, rare earth element applications, environmental catalysts, and OLED materials. Zirconium sputtering targets have a high melting point of 1852.0 °C and a 6506 kg/m³ density, making them indispensable in aerospace, automotive, electronics, energy storage, and pharmaceuticals.

Back bonding service for sputtering targets is available.

When comparing rotatory targets with planar targets, it is evident that rotatory targets offer several advantages. They contain more material, leading to greater utilization, longer production runs, and reduced system downtime, thereby increasing the throughput of the coating equipment. Additionally, the use of higher power densities is enabled due to the even spread of heat build-up over the surface area of the target. This results in increased deposition speed and improved performance during reactive sputtering.

Zirconium Sputtering Targets play a crucial role in various applications, primarily in thin film deposition processes using physical vapor deposition (PVD) techniques. Here are some critical applications and features associated with Zirconium Sputtering Targets:

The use of Zirconium Sputtering Targets is versatile, and their applications continue to expand with ongoing advancements in materials science and technology.

Our Zirconium Sputtering Targets are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.