Menu

Material: WNiFe Tungsten Heavy Alloy

Standard: ASTM B777 / MIL-T-21014 / SAE-AMS-T-21014

Shape & Size: Per Your Drawings

Applications: Used in military applications for fragmentation munitions, artillery shells, and grenades, as well as in industrial applications for radiation shielding and as counterweights in machinery.

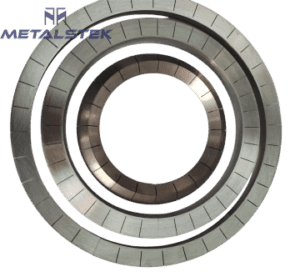

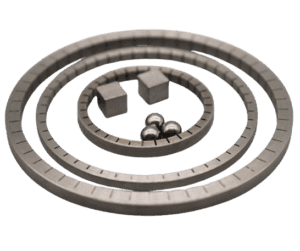

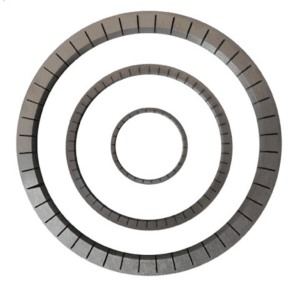

Tungsten circle rings are precision-engineered components crafted from tungsten heavy alloys, typically composed of tungsten combined with nickel and iron (WNiFe) or nickel and copper (WNiCu). These materials provide the rings with unique properties that make them suitable for high-stress environments, such as those found in weapon systems.

ASTM B777 (MIL-T-21014 / SAE-AMS-T-21014) is a standard specification for Tungsten Heavy Alloys (WHA). The specification is organized into four classes (1-4). Each categorization or classification represents a percentage amount of Tungsten (W) Alloy.

Class 1: W 90%

Class 2: W 92.5%

Class 3: W 95%

Class 4: W 97.5%

| Tungsten Heavy Alloy Grade | WHA-17C | WHA-17F | WHA-175 | WHA-18C | WHA-18F | WHA-185 |

| ASTM B777; AMS-T-21014 Class | Class 1 | Class 2 | Class 3 | Class 4 | ||

| Type | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III |

| AMS 7725C | Type 1 | Type 2 | ||||

| Alloy Composition | 90WNiCu | 90WNiFe | 92.5WNiFe | 95WNiCu | 95WNiFe | 97WNiFe |

| 90% W | 90% W | 92.5% W | 95% W | 95% W | 97% W | |

| 6% Ni | 7% Ni | 5.25% Ni | 3.5% Ni | 3.5% Ni | 2.1% Ni | |

| 4% Cu | 3% Fe | 2.25% Fe | 1.5% Cu | 1.5% Fe | 0.9% Fe | |

| Density (g/cm3) | 17 | 17 | 17.5 | 18 | 18 | 18.5 |

| Density (lbs/in3) | 0.614 | 0.614 | 0.632 | 0.65 | 0.65 | 0.668 |

| Hardness (HRC) | 24~32 | 25~32 | 26~32 | 27~34 | 27~34 | 28~35 |

| Tensile Strength (PSI) | ≥94,000 | ≥110,000 | ≥110,000 | ≥94,000 | ≥105,000 | ≥100,000 |

| Yield Strength (PSI) 2% OFFSET | ≥75,000 | |||||

| Elongation, % in 1” | >2 | >5 | >5 | >2 | >3 | >2 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Modulus of Elasticity (PSI) | 40 x 106 | 45 x 106 | 47 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x 10E-6/°C (20°- 400°C) | 5.4 | 4.8 | 4.6 | 4.4 | 4.6 | 4.5 |

| Thermal Conductivity (cal/s*cm*K) | 0.23 | 0.18 | 0.2 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity (%IACS) | 14 | 10 | 13 | 16 | 13 | 17 |

| Magnetic Properties | NIL | Slightly Magnetic | Slightly Magnetic | NIL | Slightly Magnetic | Slightly Magnetic |

Tungsten circle rings are primarily used in the following areas:

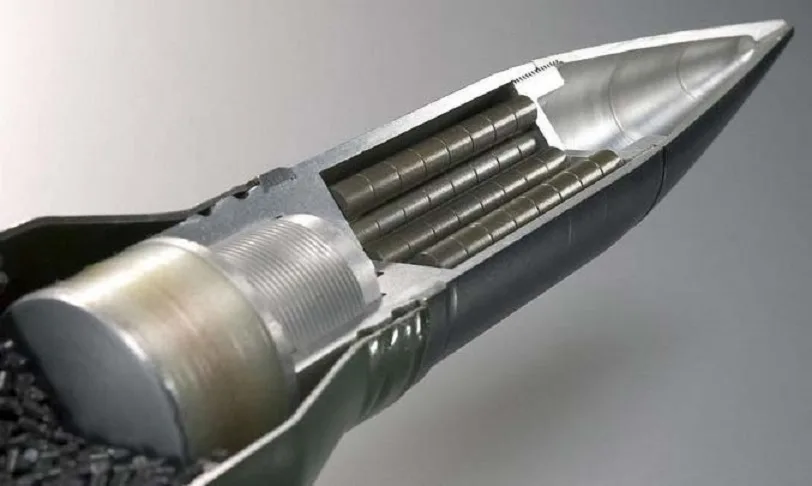

Tungsten heavy alloys are commonly used as cores for sub-caliber projectiles. The high density and strength of tungsten allow these projectiles to penetrate armor effectively. The design often involves heat treatment processes to enhance mechanical properties, ensuring that the cores maintain integrity during firing.

The exceptional penetrating capability of tungsten circle rings makes them ideal for armor-piercing ammunition. The combination of density and strength allows these rounds to deliver maximum energy upon impact, increasing their effectiveness against armored targets.

In some weapon systems, tungsten circle rings serve as ballast weights to stabilize munitions during flight. Their high density ensures that they can effectively counterbalance forces acting on the projectile, improving accuracy and performance.

Below are the other typical uses of WHA:

Our Tungsten Heavy Alloy products are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.