Menu

MetalsTek Engineering is a leading manufacturer and supplier of Silver Sputtering Target, which is for evaporation use in thin-film deposition processes. Our comprehensive offering of sputtering targets, evaporation sources and other deposition materials is listed by material throughout the website. Silver Sputtering Targets provided by MetalsTek include Ag, Pt/At, Ag/Cu, Si-Ag, Sn-Ag, and Ag2S.

Material: Silver 99.9%~99.999%

Properties: Silvery Metallic, 962°C M.P., 10.5g/cc Density

Coefficient of Thermal Expansion: 32.1 x 10-6/K

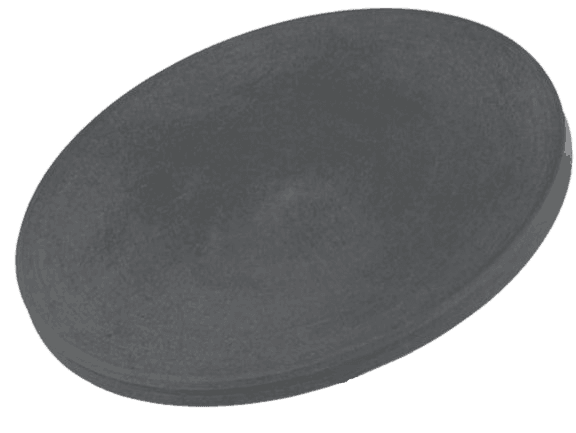

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤14” * Length≤32”

Bonding: Indium or Elastomer Bonding Recommended

Material: Platinum Silver

Purity: 99%~99.999%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤8” * Length≤14”

Main Applications: Thin-Film Deposition, Decoration, LEDs, Displays, Semiconductor, Glass Coating, Optic Coatings

Material: Silver Copper

Purity: Up to 5N, Composition can be Customized

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~14” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤8” * Length≤14”

Material: Silicon Silver 99.9%~99.999%

Properties: Silvery Metallic, 837°C M.P.

Coefficient of Thermal Expansion: 32.1 x 10-6/K

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~8” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤8” * Length≤14”

Bonding: Indium Bonding Recommended

Handling Notes

Application

Material: Tin Silver 99.9%~99.999%

Properties: Silvery Metallic, 226.5 M.W.

Coefficient of Thermal Expansion: 32.1 x 10-6/K

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~8” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤8” * Length≤14”

Bonding: Indium Bonding Recommended

Material: Tin Silver 99.9%~99.99%

Properties: Gray to Black, 825°C M.P., Sputter RF, RF-R, DC

Coefficient of Thermal Expansion: 32.1 x 10-6/K

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Sizes: Disc – Dia. 1”~8” * Thick 0.125” / 0.25”

Block – Thick≥1mm * Width ≤8” * Length≤14”

Bonding: Indium Bonding Recommended

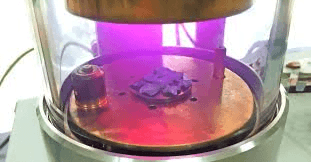

Silver Sputtering Targets are available in high purities ranging from 99.9% to 99.999%, ensuring quality deposition for applications like decorative coatings, antibiotic coatings in medical devices, large area coatings for fuel cells, and more. Silver’s exceptional properties, including its high electrical and thermal conductivity, make it a valuable material for various technological advancements. Additionally, silver sputtering targets are utilized in electronics, glass coating, wear-resistant materials, high-temperature corrosion resistance, and high-grade decorative goods. The availability of customized shapes, sizes, and purities caters to specific industry needs, with bonding services like indium bonding and elastomeric target bonding enhancing their application versatility. These targets are crucial in semiconductor deposition, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications due to their high purity and performance characteristics

Silver is a versatile and lustrous transition metal that has played a significant role in history and continues to have a wide range of modern applications. It has a melting point of 962°C, a density of 10.5 g/cc, and a vapor pressure of 10-4 Torr at 1,105°C. Silver’s properties extend beyond its aesthetic appeal and include notable ductility and malleability. It is also the most electrically conductive metal, which makes it an essential component in various industries. Silver is not only used in jewelry for ornamental purposes, but it also finds its way into various products such as solders, paints, and mirrors. Moreover, it plays a crucial role in advanced technologies, where it is evaporated under vacuum conditions to produce semiconductors, sensors, fuel cells, and optical coatings. This adaptability and importance in modern manufacturing processes showcase the significance of silver in various fields.

Silver Sputtering Targets find diverse applications in various industries due to their exceptional properties and high purity levels. Here are some key applications based on the provided search results:

Silver Sputtering Targets are available in various forms such as circular, rectangular, ring-shaped targets, and can be customized based on specific industry requirements. The bonding services offered by suppliers like indium bonding and elastomeric target bonding enhance the versatility of these targets for different applications

We take great care when handling our sputtering target materials to prevent any potential damage during storage or transportation. Through this careful approach, we ensure that our products maintain their original quality and integrity throughout the entire process, which keeps them in their pristine condition for optimal performance upon their arrival.