In today’s rapidly evolving world of technology, innovation is the key to staying ahead of the game. One breakthrough that is revolutionizing the way we power our modern devices is the use of mesh electrodes. These advanced structures have the ability to unleash the full potential of devices by providing a highly efficient and versatile solution for energy transfer. Mesh electrodes are designed with a unique interconnected structure, allowing for enhanced conductivity and improved energy distribution. This innovative design opens up a world of possibilities in various industries, from wearable technology to renewable energy systems. By maximizing power transfer and minimizing unnecessary resistance, mesh electrodes enable devices to function at their peak performance. Furthermore, the flexibility and scalability of mesh electrodes make them ideal for creating lightweight and compact designs, perfect for today’s portable devices. Whether it’s improving battery life in smartphones or enhancing the efficiency of solar panels, mesh electrodes are at the forefront of driving innovation and pushing the boundaries of what’s possible in modern technology. As we continue to push the limits of what technology can achieve, mesh electrodes provide the power and versatility needed to unlock the full potential of our devices. Join us as we delve into the exciting world of mesh electrodes and explore their game-changing capabilities in powering innovation.

What Are Mesh Electrodes?

Mesh electrodes are a type of electrode made from a network of conductive materials, typically metals or alloys. This network forms a mesh-like structure, providing a high surface area and excellent flexibility. Common materials used for mesh electrodes include Titanium, Platinum, Nickel, Aluminum, Copper and various refractory metals such as Tungsten and Molybdenum. These materials are chosen for their conductivity, durability, and biocompatibility, making mesh electrodes suitable for a wide range of applications.

The Role of Mesh Electrodes in Modern Technology

Mesh electrodes play a pivotal role in modern technologies due to their unique properties and advantages over traditional planar electrodes. These three-dimensional (3D) mesh or grid-like structures offer several key benefits:

- Increased Surface Area: The mesh design provides a significantly larger electrochemically active surface area compared to planar electrodes. This enhanced surface area improves the performance of electrochemical processes, such as energy storage devices, fuel cells, and electrochemical sensors.

- Flexibility and Conformity: The mesh structure allows the electrode to conform to curved or irregular surfaces, making it suitable for applications like neural interfaces and biomedical devices. Mesh electrodes can adapt to the contours of tissues or organs, enabling minimally invasive implantation and reducing tissue damage.

- Depth Selectivity: By adjusting the length of the mesh elements, different functional layers within tissues or materials can be accessed, enabling depth-selective sensing or stimulation. This is particularly useful in neural interfaces for acquiring signals from various brain regions.

- Transparent Electrodes: Mesh electrodes can be fabricated with materials like metals or conductive oxides to create transparent or semi-transparent electrodes. These electrodes find applications in optoelectronic devices, such as organic light-emitting diodes (OLEDs), solar cells, and displays.

- Enhanced Light Absorption: In organic solar cells, mesh electrodes can couple incident light to surface plasmon polariton (SPP) modes, leading to enhanced light absorption in the active layer and improved device performance.

- Electromechanical Actuators: Mesh electrodes have been employed in ionic polymer-metal composite (IPMC) actuators, where the increased surface area and conformity of the mesh electrode contribute to improved actuation performance and displacement.

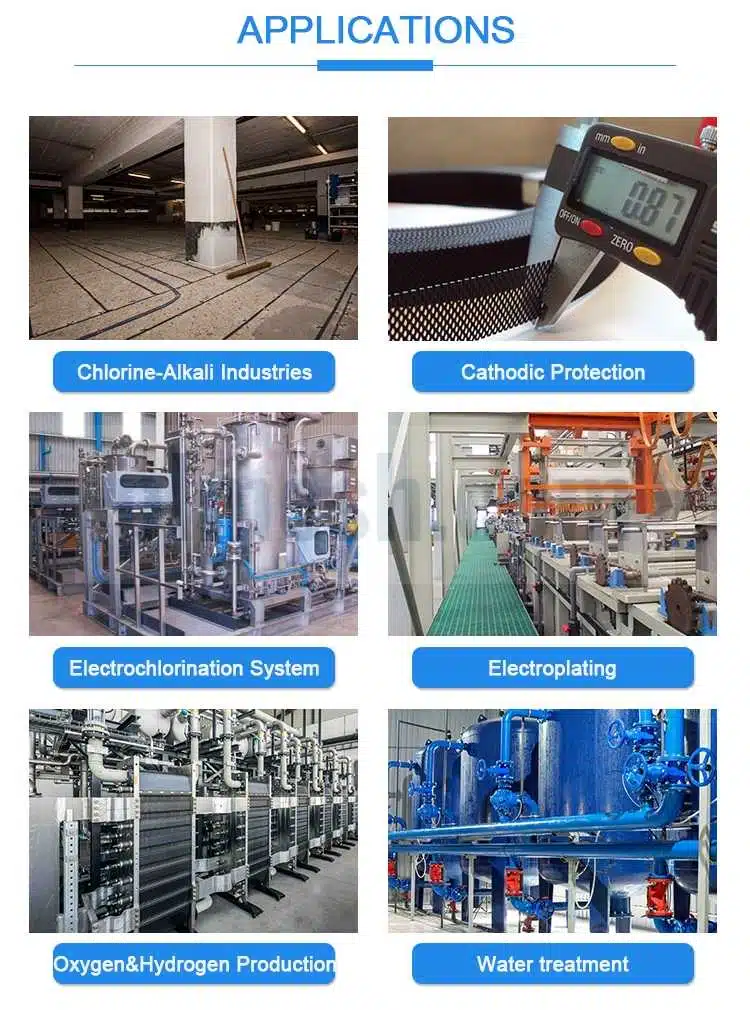

Applications of Mesh Electrodes in Various Industries

Mesh electrodes find applications in various industries, including:

- Energy Storage and Conversion: Electrodes for batteries, fuel cells, and electrochemical capacitors, benefiting from the high surface area. In energy storage systems, mesh electrodes play a crucial role in developing high-efficiency batteries and supercapacitors. Their structure allows for superior ion flow and storage capacity, leading to more efficient and durable energy storage solutions.

- Biomedical Devices: In the medical industry, mesh electrodes are used in neural interfaces and biosensors. Their flexibility and biocompatibility allow for integration with biological tissues, providing accurate and reliable monitoring and stimulation.

- Environmental Monitoring: Mesh electrodes enhance the sensitivity and accuracy of environmental sensors used for pollution detection and chemical analysis. Their large surface area facilitates better interaction with target molecules, improving sensor performance.

- Optoelectronics: Transparent and flexible electrodes for organic light-emitting diodes (OLEDs), solar cells, and displays.

Advantages of using mesh electrodes

Mesh electrodes offer several advantages over traditional solid electrodes:

- Flexibility: Their flexible structure is ideal for applications requiring conformity to complex surfaces, such as wearable sensors.

- Conductivity: The network design enhances electrical conductivity, improving overall performance in various applications.

- Large Surface Area: The increased surface area of mesh electrodes enhances their electrochemical performance, making them more efficient in energy storage and sensor applications.

Manufacturing Techniques

Producing high-quality mesh electrodes involves several advanced fabrication techniques:

- Chemical Vapor Deposition (CVD): This method allows for precise deposition of materials, creating a uniform mesh structure.

- Electroplating: This technique provides a controlled way to deposit metal layers onto a substrate, forming the mesh.

- Laser Cutting: Laser cutting allows for high precision in creating custom shapes and sizes for specific applications.

At MetalsTek, we offer extensive customization options to meet the unique needs of our clients, ensuring that our mesh electrodes are tailored to their specific requirements.

Innovations and Advancements

Advancements in mesh electrode technology include:

- Fabrication Techniques: Lithographic methods, template-guided immobilization, electrochemical deposition, and direct writing techniques like 3D printing enable precise control over mesh dimensions, surface area, and material properties.

- Material Selection: A wide range of conductive materials, including metals, metal oxides, and conductive polymers, can be used to tailor mesh electrodes for specific applications.

- Customization: Mesh electrodes can be customized in terms of size, surface area, and material composition to meet specific performance needs, such as increased electrochemically active surface area, flexibility, or depth selectivity.

- Integration with Flexible Substrates: Mesh electrodes can be integrated with flexible substrates, enabling conformity to curved or irregular surfaces and minimally invasive implantation in biomedical applications.

How to choose the right mesh electrode for your project

Ensuring the highest quality in mesh electrodes is essential for their performance and longevity. Material purity and manufacturing precision are critical factors. Impurities can affect conductivity and biocompatibility, while precise manufacturing ensures the structural integrity of the mesh.

When selecting a mesh electrode for a project, consider factors such as:

- Application Requirements: Evaluate the specific needs of your application, such as surface area, flexibility, transparency, or depth selectivity, to determine the most suitable mesh electrode design.

- Material Properties: Choose the appropriate conductive material based on factors like conductivity, biocompatibility, and chemical resistance, depending on the application environment.

- Fabrication Capabilities: Assess the available fabrication techniques and their ability to produce the desired mesh electrode specifications, such as dimensions, surface area, and material composition.

- Cost and Scalability: Consider the cost-effectiveness and scalability of the mesh electrode production process for your project’s requirements.

At MetalsTek, we adhere to stringent quality control measures, utilizing advanced techniques to guarantee the purity and consistency of our products.

Why MetalsTek Engineering?

- Expertise in Precision Engineering and Quality Control:

MetalsTek Engineering prides itself on its precision engineering capabilities and rigorous quality control processes. This ensures that their zirconium carbide offerings excel in applications where hardness, thermal stability, and wear resistance are critical. Their expertise allows them to produce high-quality materials that meet the demanding requirements of various industries. - Customization and Tailored Solutions:

MetalsTek Engineering offers customization options for our mesh electrodes, including materials, purity levels (99% to 99.999%), and specific surface areas. This flexibility allows us to tailor our materials to meet the specific needs of different applications and customers. - Advanced Materials and Production Processes:

MetalsTek Engineering utilizes efficient and environmentally friendly production methods. Our expertise in advanced materials and production processes enables us to provide high-quality products while minimizing environmental impact. - Commitment to Quality and Identification:

MetalsTek Engineering takes great care in ensuring efficient identification and quality control of our products. Our meshes are clearly tagged and labeled externally to avoid damage during storage or transportation, demonstrating its commitment to delivering high-quality materials to its customers.

By choosing MetalsTek Engineering, customers can benefit from our expertise, customization capabilities, advanced production processes, diverse product offerings, and commitment to quality, making us a reliable and trusted partner for mesh electrodes and other advanced materials.

Challenges and Limitations

While mesh electrodes offer numerous advantages, there are also challenges and limitations to consider:

- Fabrication Complexity: Producing intricate mesh structures with precise control over dimensions and material properties can be challenging and may require advanced fabrication techniques.

- Material Limitations: Some conductive materials may have limitations in terms of mechanical properties, chemical stability, or biocompatibility, depending on the application.

- Integration Challenges: Integrating mesh electrodes with other components or systems, such as flexible substrates or electronic circuits, can pose challenges in terms of interconnections and packaging.

- Cost: Depending on the fabrication process and materials used, mesh electrodes may be more expensive than traditional planar electrodes, particularly for large-scale production.

Future Prospects and Potential

The future prospects and potential of mesh electrodes are promising, with ongoing research and development efforts focused on:

- Scalable and Cost-Effective Fabrication: Developing scalable and cost-effective fabrication techniques to enable widespread adoption of mesh electrodes in various applications.

- Advanced Materials: Exploring new conductive materials with improved properties, such as higher conductivity, better mechanical strength, or enhanced biocompatibility, for specific applications.

- Integration with Flexible Electronics: Integrating mesh electrodes with flexible electronics and wearable devices for applications in healthcare, environmental monitoring, and human-machine interfaces.

- Multifunctional Mesh Electrodes: Developing mesh electrodes with multiple functionalities, such as sensing, stimulation, and drug delivery, for advanced biomedical applications.

- Energy Storage and Conversion: Leveraging the high surface area of mesh electrodes to improve the performance of energy storage devices, such as batteries and supercapacitors, and energy conversion systems like fuel cells.

As research and development in mesh electrode technology continue, we can expect to see more innovative applications and solutions that harness the unique properties of these versatile electrodes.

Conclusion: Harnessing the Power of Mesh Electrodes for a Better Future

Mesh electrodes are revolutionizing modern technology with their unique properties and versatile applications. From biomedical devices to energy storage, their benefits are clear. As the demand for advanced materials continues to grow, choosing a reliable supplier is crucial. At MetalsTek, we pride ourselves on our expertise and dedication to quality, making us the ideal partner for your mesh electrode needs. Contact us today to learn more about how our mesh electrodes can enhance your projects and drive innovation.

MetalsTek Engineering is a leading manufacturer of mesh electrodes. It leverages advanced fabrication techniques to produce customized mesh electrodes with precise control over dimensions, surface area, and material properties. Its expertise in material selection and quality control positions it as a leader in providing tailored mesh electrode solutions for diverse applications across various industries.