Menu

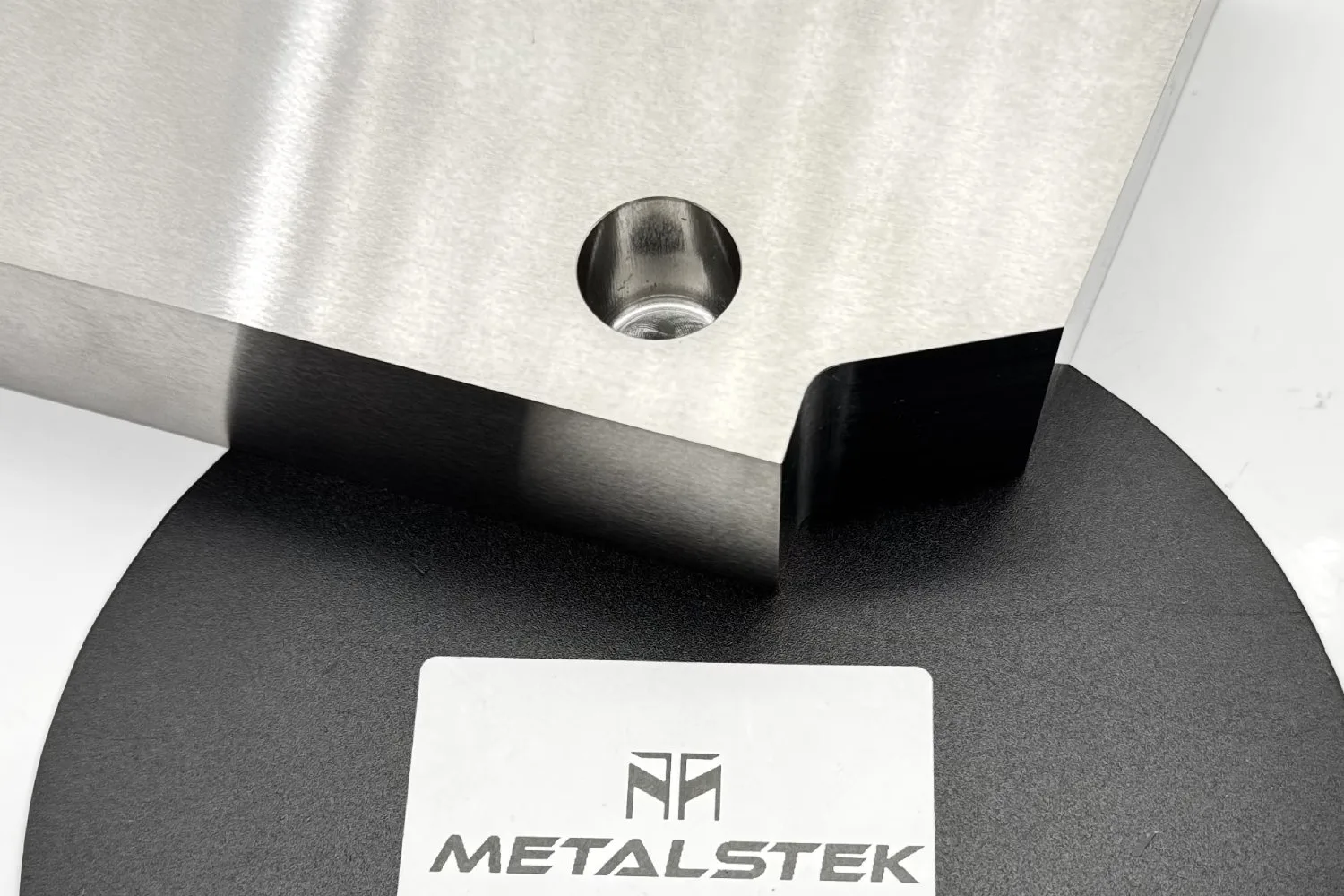

MetalsTek Engineering supplies super-quality Tungsten Heavy Alloys(WHAs) such as Tungsten Nickel Iron (WNiFe) Alloy, Tungsten Nickel Copper (WNiCu) Alloy, in ASTM B777 (MIL-T-21014 / SAE-AMS-T-21014) Class 1, 2, 3 and 4, for different applications. The WHAs include Ballast Weights, Powder, Rod, Discs, Rod Slugs, Block and Bars, Sheet, Plates, Rings, Pipes, Sphere Balls, Shielding, Targets, and more.

Tungsten-heavy Alloys (WHAs) are created by combining tungsten with two-phase NiFe, NiCo, or NiCu composites, forming a ductile matrix. Tungsten has been strengthened by adding elements like Nickel, Iron, Copper, Cobalt, Moly, and Chromium. These alloys boast excellent machining properties, impressive radiation resistance, a lower expansion coefficient, and a high strength and modulus of elasticity.

Due to these qualities, WHAs find extensive applications, especially in military equipment, as ballast weights for submarines and vehicles, aircraft components, nuclear and medical shields, boring bars, ordnance components and other applications which require high density and superior ductility.

ASTM B777 (MIL-T-21014 / SAE-AMS-T-21014) is a standard specification for Tungsten Heavy Alloys (WHA). The specification is organized into four classes (1-4). Each categorization or classification represents a percentage amount of Tungsten (W) Alloy.

Class 1: W 90%

Class 2: W 92.5%

Class 3: W 95%

Class 4: W 97.5%

| Tungsten Heavy Alloy Grade | WHA-17C | WHA-17F | WHA-175 | WHA-18C | WHA-18F | WHA-185 |

| ASTM B777; AMS-T-21014 Class | Class 1 | Class 2 | Class 3 | Class 4 | ||

| Type | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III | Type II & III |

| AMS 7725C | Type 1 | Type 2 | ||||

| Alloy Composition | 90WNiCu | 90WNiFe | 92.5WNiFe | 95WNiCu | 95WNiFe | 97WNiFe |

| 90% W | 90% W | 92.5% W | 95% W | 95% W | 97% W | |

| 6% Ni | 7% Ni | 5.25% Ni | 3.5% Ni | 3.5% Ni | 2.1% Ni | |

| 4% Cu | 3% Fe | 2.25% Fe | 1.5% Cu | 1.5% Fe | 0.9% Fe | |

| Density (g/cm3) | 17 | 17 | 17.5 | 18 | 18 | 18.5 |

| Density (lbs/in3) | 0.614 | 0.614 | 0.632 | 0.65 | 0.65 | 0.668 |

| Hardness (HRC) | 24~32 | 25~32 | 26~32 | 27~34 | 27~34 | 28~35 |

| Tensile Strength (PSI) | ≥94,000 | ≥110,000 | ≥110,000 | ≥94,000 | ≥105,000 | ≥100,000 |

| Yield Strength (PSI) 2% OFFSET | ≥75,000 | |||||

| Elongation, % in 1” | >2 | >5 | >5 | >2 | >3 | >2 |

| Proportional Elastic Limit (PSI) | 45,000 | 52,000 | 46,000 | 45,000 | 44,000 | 45,000 |

| Modulus of Elasticity (PSI) | 40 x 106 | 45 x 106 | 47 x 106 | 45 x 106 | 50 x 106 | 53 x 106 |

| Coefficient of Thermal Expansion x 10E-6/°C (20°- 400°C) | 5.4 | 4.8 | 4.6 | 4.4 | 4.6 | 4.5 |

| Thermal Conductivity (cal/s*cm*K) | 0.23 | 0.18 | 0.2 | 0.33 | 0.26 | 0.3 |

| Electrical Conductivity (%IACS) | 14 | 10 | 13 | 16 | 13 | 17 |

| Magnetic Properties | NIL | Slightly Magnetic | Slightly Magnetic | NIL | Slightly Magnetic | Slightly Magnetic |

There are many different ways to use WHA. Mostly, we provide Tungsten Heavy Alloy parts for ballast weights, radiation shields, boring bars, ordnance components, and other things that need to be really heavy and flexible.

Tungsten heavy alloy (WHA) is commonly used in various applications, such as counterweights, inertial masses, radiation shielding, and ordnance products. It is preferred for its strength, density, and weight, making it suitable for applications that require balance weights, such as turbines, crankshafts, and helicopter rotors.

WHA is also used in commercial and military aircraft, spacecraft, defense vehicles, transportation systems, warheads, munitions, and fragmentation.

In the medical industry, WHAs are used for X-ray shielding in applications such as CT and imaging technologies, nuclear medicine shielding, and surgical robots. The alloying of tungsten allows for the production of complex shapes and forms needed for critical medical devices and technologies.

Below are the typical uses of WHA:

Our Tungsten Heavy Alloy (WNiFe, WNiCo, WNiCu) are meticulously tagged and externally labeled, ensuring both efficient identification and rigorous quality control. We prioritize utmost care to prevent any potential damage that may occur during storage or transportation.

In the realm of advanced materials, tungsten heavy alloys stand out as a cornerstone for industries that demand nothing less than the highest density and strength. These alloys, known for their unparalleled combination of robustness, durability, and precision, are pivotal in applications ranging from aerospace counterweights to medical shielings. This article dives into the intricate world of tungsten heavy alloy specifications, production processes, and their multifaceted applications, offering insights into why these materials are indispensable in pushing the boundaries of technological advancement, what need to be considered when making purchases.

Tungsten heavy alloys are designed to be a high-density solution, ranging from 17 to 18.5 grams per cubic centimeter. They come in customized forms such as rods, sheets, counterweights, and radiation shielding, each made for specific needs in different industries. These products are made to strict standards, so they have exact dimensions and tight tolerances, which means you can choose from a range of weights to fit your exact needs. The customizable shapes and sizes, combined with tungsten’s natural strength, make these alloys important for solving the problems of advanced engineering and technology.

The defining feature of tungsten heavy alloys is their distinctive blend, composed chiefly of tungsten and supplemented by nickel, and either iron or copper. This combination is meticulously engineered to harness both exceptional density and robust mechanical fortitude. The result is an alloy with an unrivaled weight-to-volume ratio that steadfastly endures against thermal expansion and corrosion. These properties make tungsten heavy alloys indispensable in high-stress situations, from aerospace to medical technology, providing unwavering performance where lesser materials would falter.

Creating tungsten heavy alloys is a testament to the precision of modern powder metallurgy. It starts with blending fine tungsten powder with metallic elements. This mixture is then compressed under immense pressure to form a shape. Heat is then applied in a sintering process that bonds the particles at a molecular level, resulting in a dense and durable material. This material is then machined into various forms, such as rods, sheets, and custom-designed counterweights and shieldings, meeting the specifications required by industries that demand high quality and performance.

Tungsten heavy alloys showcase their remarkable versatility through an extensive portfolio of shapes and forms tailored to multifaceted industrial needs. Rods and sheets are engineered to provide structural integrity in demanding applications. Counterweights are precision-crafted to deliver exact balance in aerospace and automotive systems, whereas shieldings are specifically designed to offer robust protection in medical and nuclear industries. The range is further extended to include discs, blocks, and spheres, each embodying the alloy’s malleability and suitability for diverse operational challenges, confirming the material’s adaptability and utility across a spectrum of sophisticated engineering tasks.

Tungsten heavy alloys are highly esteemed for their impressive density, an attribute indispensable in applications where significant mass must be contained within constrained volumes.

Their exceptional mechanical characteristics are characterized by formidable tensile strength and commendable ductility, making them exceedingly resilient under stress.

Moreover, their proficiency in radiation shielding is unparalleled, providing critical protection in medical, scientific, and aerospace industries.

These combined qualities underscore their extensive applicability and make them an invaluable resource in sectors where performance and reliability are paramount.

Tungsten heavy alloy products are known for their commitment to meeting industry and global quality standards, showing a dedication to excellence. This commitment means that these materials meet the strict requirements of many different applications. They find the perfect balance between performance and reliability, making them the go-to choice for industries where mistakes are not an option.

Our production facility is the foundation of our strong supply capabilities. We have flexible manufacturing lines and lots of customization options. This means we can easily switch from making small prototypes to doing big production runs. We are dedicated to meeting our clients’ special requirements with great accuracy. We make sure every order, no matter how big or small, is done with great attention to detail and tailored precision to meet unique demands.

Tungsten heavy alloys are used in a wide range of applications.

These examples show how important and versatile tungsten heavy alloys are in different industries.

Surface finishing processes greatly enhance the performance and appearance of tungsten heavy alloys. Polishing gives the alloy a shiny finish, reduces surface roughness, and minimizes friction. Precision machining shapes and textures the alloy to precise dimensions and tolerances, making it work perfectly in its intended application. Advanced coating techniques, such as Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD), apply a thin layer that makes the alloy more resistant to wear and corrosion, protecting it in different and often difficult working conditions. These finishing steps are important because they make the products last longer and work better in specific environments and industries.

Our commitment to quality is evident in our strict quality control measures, which are specifically designed to ensure the reliability and performance of our tungsten heavy alloy products. Our material testing procedures confirm the composition and properties of the alloys, ensuring that they meet high-density and strength criteria. Every product is checked with precision instruments to confirm that they adhere to specified tolerances.

We meticulously observe safety standards, making certain that our products are safe and reliable for their intended applications. Our thorough and comprehensive approach to quality assurance ensures that every product we deliver not only meets but exceeds industry standards, providing our clients with superior materials that are built to last.

All of our products meet the following requirements: DFARS 252.225-7001 Buy American Act; DFARS 252.225-7009 Specialty Metals; DFARS 252.225-7052 Magnets and Tungsten. All of our products also comply with EU RoHS Directive 2015/863 and with Regulation (EC) No. 1907/2006 of The European Parliament and of the Council concerning the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH). We do not intentionally add mercury or mercury-containing compounds to our products, and they do not come into direct contact with any hardware or supplies provided under this purchase order. According to Section 1502 (“the Provision”) of the Dodd-Frank Wall Street Reform and Consumer Protection Act (“Act”) (Pub. L. 111-203, 124 Stat. 1376, July 21, 2010), also known as the “Conflict Minerals Act”, we only purchase minerals that are “DRC conflict-free” from smelters on the Conflict-Free Smelter Program (CFSP) Compliant Smelter list.

We know how important it is to get your order to you quickly and safely. That’s why we’ve built a strong shipping and logistics system. We’ve designed our system to handle all kinds of tungsten heavy alloy products, no matter how big or small. We use special packing methods, trusted shipping partners, and tracking tools to make sure your order arrives on time and in great shape. We take shipping seriously because we want to make sure you get what you need, when you need it. We’re committed to giving you great service every step of the way.

Choosing the right tungsten heavy alloy for a specific application is a complex process. It requires a deep understanding of the conditions the alloy will face. Our team works closely with clients to determine their specific density needs, mechanical stress factors, and any corrosive or temperature extremes the product may encounter.

By combining our technical expertise with our clients’ needs, we make sure the alloy not only meets but is perfectly suited to the application’s requirements. This customer-focused process is crucial to our service, guaranteeing that each material recommendation is the best fit for the intended use.

At MetalsTek, our expertise extends beyond merely selling products; we specialize in creating them. Understanding that off-the-shelf solutions don’t always meet unique requirements, we provide bespoke design and machining services tailored to your specific needs. Collaborating closely with you, we aim to craft a solution that aligns perfectly with your objectives. Utilizing state-of-the-art equipment and backed by a team of skilled professionals, we ensure your custom designs are executed precisely to match your exact specifications. Our commitment lies in being more than a supplier; we strive to be a comprehensive partner in your success, offering support beyond transactions to facilitate your achievements.

At MetalsTek, we pride ourselves on our commitment to providing top-quality materials. Our extensive product range covers a wide range of applications, all of which meet the highest standards of quality and reliability. We don’t just supply materials; we also offer tailored solutions that perfectly meet our customers’ needs. Our expertise and precision in design and manufacturing set us apart from the competition and make us the preferred partner for industry leaders who want the best materials. We’re dedicated to quality at every stage, from sourcing raw materials to delivering finished products. That’s why MetalsTek is a trusted name in the industry. Our commitment to excellence is what sets us apart and makes us the obvious choice for those who want the best.

The price of Tungsten Heavy Alloys (WHAs) is influenced by several factors. These include the purity of the materials used, the complexity of the shape and size of the product, and the size of the order. If the materials used are very pure or if the design is very complex, the cost will be higher. This is because more advanced production techniques and strict quality control measures are needed. The size of the order also matters. If the order is very large, the price per unit may be lower because of economies of scale.

Standard WHA products are available at a wide range of prices. This is because they are high-performance products that are used in demanding applications. However, if you want a custom product that is made to your specifications, it may cost more. This is because it is more difficult to design and manufacture custom products.

If you are considering a custom WHA product, keep in mind that the extra cost is often worth it. This is because the product will perform better and fit your application better. In the long run, this will give you better value for your money.

When it comes to buying tungsten heavy alloys, there are a lot of things to think about. You need to know what you’re going to use it for, how it will hold up in different environments, and if it will work with your existing stuff. You also need to know what the material is like so you can make sure you’re getting the right alloy for what you need.

We’re really good at this stuff. We’ve been doing it for a long time and we’re really good at it. We don’t just sell you stuff, we sell you peace of mind. We’re really good at what we do because we’re really honest, we work with you, and we do things the right way. We’re here to help you make the right decision and make sure you get the right alloy for what you need.

MetalsTek understands the importance of tungsten heavy alloys in advancing technology and industry. Our products are known for their density, strength, and versatility. We offer a wide range of tungsten heavy alloy products, ensuring high quality and excellent customer service. Our clients in various industries, such as aerospace and healthcare, trust MetalsTek to provide alloys that meet and exceed their needs. Whether it’s for aerospace counterweights or medical radiation shields, our materials are designed for superior performance. When you choose MetalsTek, you can be confident that you’re choosing the best material for your application.