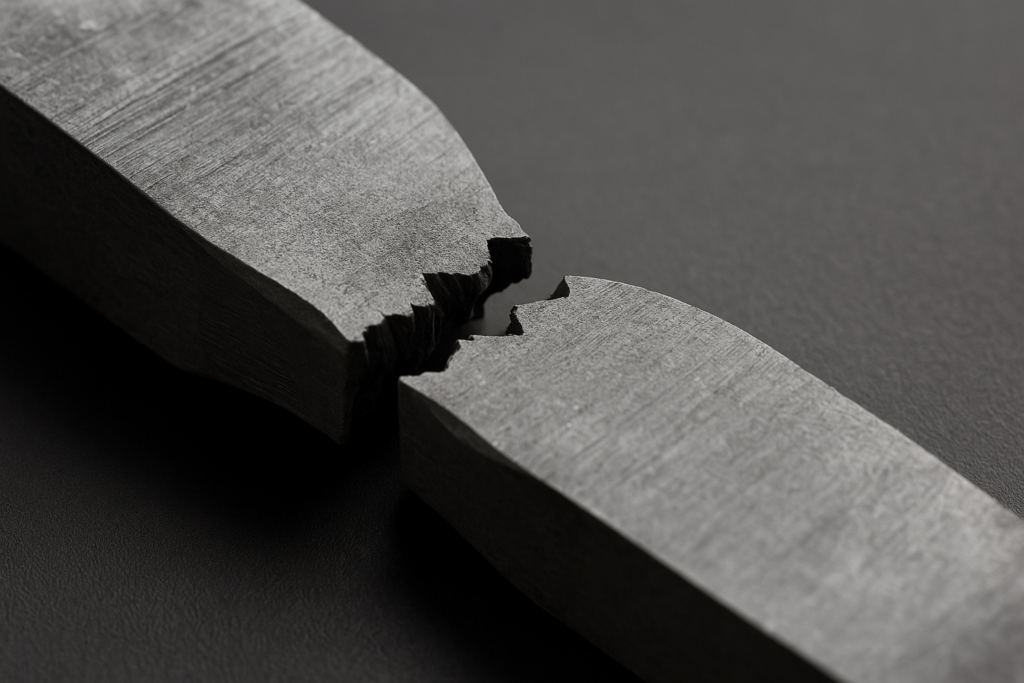

In the world of engineering and high-tech manufacturing, metals are trusted for their strength, resilience, and durability. From towering bridges and high-speed rail to aerospace engines and semiconductor components, metals hold everything together—literally. But here’s the catch: even the strongest metals can sometimes break without warning. Like a snapped pencil or shattered glass, the break is sudden, catastrophic, and often without any visible signs. This phenomenon is known as metal brittleness, and it’s a silent threat you can’t afford to ignore.

So, What Is Metal Brittleness?

Metal brittleness refers to a material’s tendency to fracture suddenly, without significant plastic deformation or visible warning. Unlike ductile failure, which shows signs like bending or stretching before breaking, brittle fracture happens fast and clean—often with disastrous consequences.

Despite their usual strength and toughness, metals can become brittle due to temperature changes, stress concentrations, or internal flaws. The result? They fail under conditions they would normally withstand with ease.

3 Main Types of Metal Brittleness

Let’s break down the common forms of metal brittleness seen in industrial applications:

1. Low-Temperature Brittleness

Some metals, like carbon steel, become significantly less ductile as temperatures drop. This is known as the ductile-to-brittle transition. For instance, a steel component that performs flawlessly at room temperature might snap like a twig in sub-zero environments—think Arctic installations, LNG storage, or deep-sea applications.

2. Stress Concentration Brittleness

Tiny notches, cracks, or weld seams can act as stress amplifiers. Even when the overall stress level is within the metal’s limits, localized stress spikes can cause cracks to initiate and propagate rapidly—especially in brittle materials.

3. Dynamic Load Brittleness

Under high-speed impacts or sudden loads—like explosions, collisions, or machinery malfunctions—metals may fracture before they have time to deform plastically. The metal behaves more like ceramic under these conditions.

What Causes Metal Brittleness?

It’s not just one factor—it’s a complex interplay of material structure, environmental conditions, and manufacturing processes. Let’s dive deeper:

Internal Factors

- Crystal Structure: Metals with body-centered cubic (BCC) structures, like iron and chromium, have fewer slip systems and are more brittle at low temperatures than face-centered cubic (FCC) metals like copper or aluminum.

- Grain Size: Finer grains improve toughness; larger or uneven grains promote brittleness.

- Impurities & Inclusions: Non-metallic inclusions (e.g., oxides, sulfides) or poorly bonded secondary phases often act as crack initiation points.

External Factors

- Temperature: Low temperatures reduce atomic mobility, increasing brittleness. Conversely, excessive heat can lead to creep or thermal cracking.

- Corrosive Environments: Chloride-induced stress corrosion cracking (SCC) in stainless steel is a notorious example where corrosion and tension combine to initiate brittle cracks.

Process-Related Factors

- Cold Working: Excessive deformation without proper annealing introduces internal stresses, reducing ductility.

- Improper Heat Treatment: Fast quenching or inadequate tempering can result in hard, brittle martensitic structures, prone to cracking.

How Can Metal Brittleness Be Reduced?

The good news? Brittleness can be mitigated through material science and process optimization. Here’s how:

1. Optimize Material Composition and Microstructure

- Use alloying elements like nickel or manganese to lower ductile-to-brittle transition temperature.

- Implement grain refinement via thermal treatments to improve toughness.

- Remove inclusions using advanced smelting and vacuum refining to minimize crack initiation sites.

2. Control the Operating Environment

- Maintain temperatures above transition thresholds in service environments.

- Apply protective coatings to prevent corrosion.

- Reduce exposure to chlorides or cyclic humidity in sensitive environments.

3. Improve Manufacturing Processes

- Minimize cold working or follow it with stress-relief annealing.

- Design proper heat-treatment cycles tailored to the alloy.

- Avoid sharp notches and sudden cross-sectional changes in part design.

Conclusion: A Systems Approach to Safer Metals

Metal brittleness isn’t a single flaw—it’s the outcome of interconnected factors. Tackling it requires a comprehensive strategy that spans material selection, environmental management, and process control. At MetalsTek, we provide advanced materials and customized alloys engineered to resist brittle failure, whether you’re designing for cryogenic conditions, high-speed aerospace components, or high-reliability electronics.

Ready to upgrade your material performance and avoid unexpected failures?

Contact us at sales@metalstek.com or visit www.metalstek.com to discuss your custom alloy and deposition material needs.