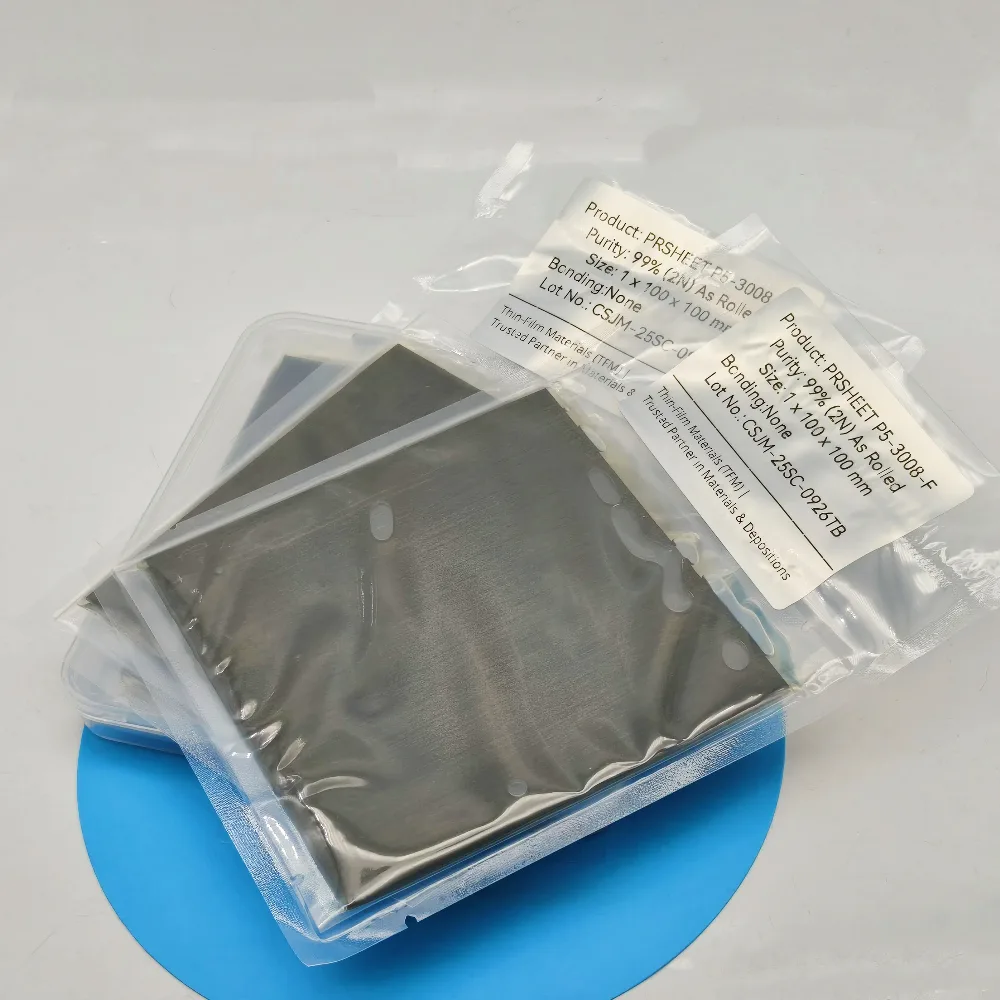

For high‑precision applications, our 1 mm thick praseodymium (Pr) metal sheets offer reliable performance, stable surface, and excellent machinability. At MetalsTek, we supply these sheets stored under protective oil to prevent oxidation, ensuring they arrive in pristine condition.

Whether you need Pr for sputtering targets, alloy research, thin film deposition, or structural testing, our 1 mm praseodymium sheets deliver the dimensional accuracy and purity demanded by advanced labs and manufacturers.

Why Choose MetalsTek’s 1 mm Praseodymium Sheets?

- Uniform 1 mm thickness with tight flatness tolerances

- High‑purity metal (you can specify, e.g. 99.9 %, 99.99 %)

- Oil packing to protect surface from oxidation during storage and transport

- Clean-cut edges with minimal burrs for easy integration

- Consistent microstructure that supports downstream fabrication and deposition

- Custom sizing — we can tailor length, width, or cuts to fit your tooling

Key Material Features & Technical Data

Here is a reference table based on known praseodymium properties. Confirm with your internal QC data for the specific lot.

| Property | Typical Value | Notes & Relevance |

|---|---|---|

| Density | ~6.77 g/cm³ | At room temperature (20 °C) |

| Melting Point | ~931 °C | Solid → liquid transition |

| Boiling Point | ~3,520 °C | For vaporization or high‑temperature behavior |

| Thermal Conductivity | ~12.5 W/(m·K) | Approximate for Pr metal at room temperature |

| Electrical Conductivity | ~1.5 × 10⁶ S/m | Typical metallic conduction behavior |

| Thickness | 1.00 mm | Manufactured sheet thickness |

| Purity | (user‑specifiable) | Common grades: 99.9 %, 99.99 % |

| Packaging | Oil‑packed | To prevent oxidation until use |

| Surface Condition | Machined, lightly polished | For ease of handling and processing |

These values serve as guidelines. Use your batch certificate of analysis (COA) to confirm exact values for each sheet.

Applications & Use Cases

- Fabrication of sputtering targets or parts using Pr

- Alloy research, especially rare-earth or magnetic materials

- Thin-film deposition backing or intermediate layers

- Test coupons, samples, or structural components in research

- Component substrate material in rare‑earth metal systems

Handling & Storage Advice

- Store sheets in their original oil packaging until ready to use

- When removing oil, use clean solvents (e.g. anhydrous alcohol) and avoid contamination

- Handle with lint‑free gloves or tweezers to avoid fingerprint or contamination

- Avoid scratching or bending—Pr is ductile but can oxidize if surface damage occurs

- For machining or cutting, use coolant and sharp tools to prevent heat buildup

You May Also Want to Know

1. Why is praseodymium stored under oil?

Because praseodymium reacts with oxygen and moisture in air, an oil layer provides a protective barrier and delays oxidation during storage and handling.

2. How uniform is the 1 mm thickness?

We hold tight flatness and thickness tolerances (e.g. ±0.01 mm or tighter, depending on sheet size) — you can specify your tolerance for critical uses.

3. What purity grades are common?

Standard high-purity levels include 99.9 % (3N), 99.99 % (4N), or higher, depending on your requirements and downstream sensitivity.

4. Can the sheet be directly used in vacuum systems?

Yes, after proper cleaning and degassing. The oil must be fully removed and the sheet pre-baked or vacuum cleaned before use.

5. What machining or cutting is possible?

Praseodymium can be milled, laser cut, EDM‑ed, or waterjet cut. Use low temperature and clean environments to avoid surface oxidation or inclusion.

6. How does thermal cycling affect the sheet?

Because of the ductile nature of Pr, it tolerates moderate thermal cycling, but avoid extreme gradients or rapid temperature changes to mitigate stress.

7. What is the coefficient of thermal expansion (CTE)?

The CTE is modest for lanthanide metals; verify with internal data for your lot. When integrating with dissimilar materials, design for expansion mismatch.

8. Is praseodymium reactive or hazardous?

In solid bulk form, it’s relatively stable in controlled environments. However, fine dust or powders are more reactive. Standard lab safety and handling protocols apply.

9. Can we customize sheet cuts?

Yes — we can cut to your requested lengths, widths, or shapes (slots, holes) as part of the order. Provide your drawings.

10. What is the lead time for 1 mm Praseodymium sheet orders?

Typical lead times range from a few weeks to several weeks depending on purity, quantity, and cut complexity.

11. How is material purity verified?

Using high-sensitivity methods such as GDMS or ICP-MS, with COA provided for each batch.

12. What are common failure modes?

Surface oxidation after cleaning, warping from stress, contamination during handling, or thickness variation outside tolerance.