Welcome to MetalsTek Engineering’s essential guide to Crucible Tongs! Whether you’re a seasoned chemist, an innovative researcher, or a budding student in the lab, you know that handling crucibles demands precision, safety, and the right tools. Crucible tongs are not just an accessory—they are a necessity for ensuring your work remains efficient and hazard-free.

In this complete review, we’ll dive into everything you need to know about selecting the perfect crucible tongs. From materials and design to durability and functionality, we’ll help you navigate the options with confidence. At MetalsTek Engineering, we believe informed decisions lead to better outcomes, and our guide is here to empower you in making the right choice for your lab needs.

Table of Contents

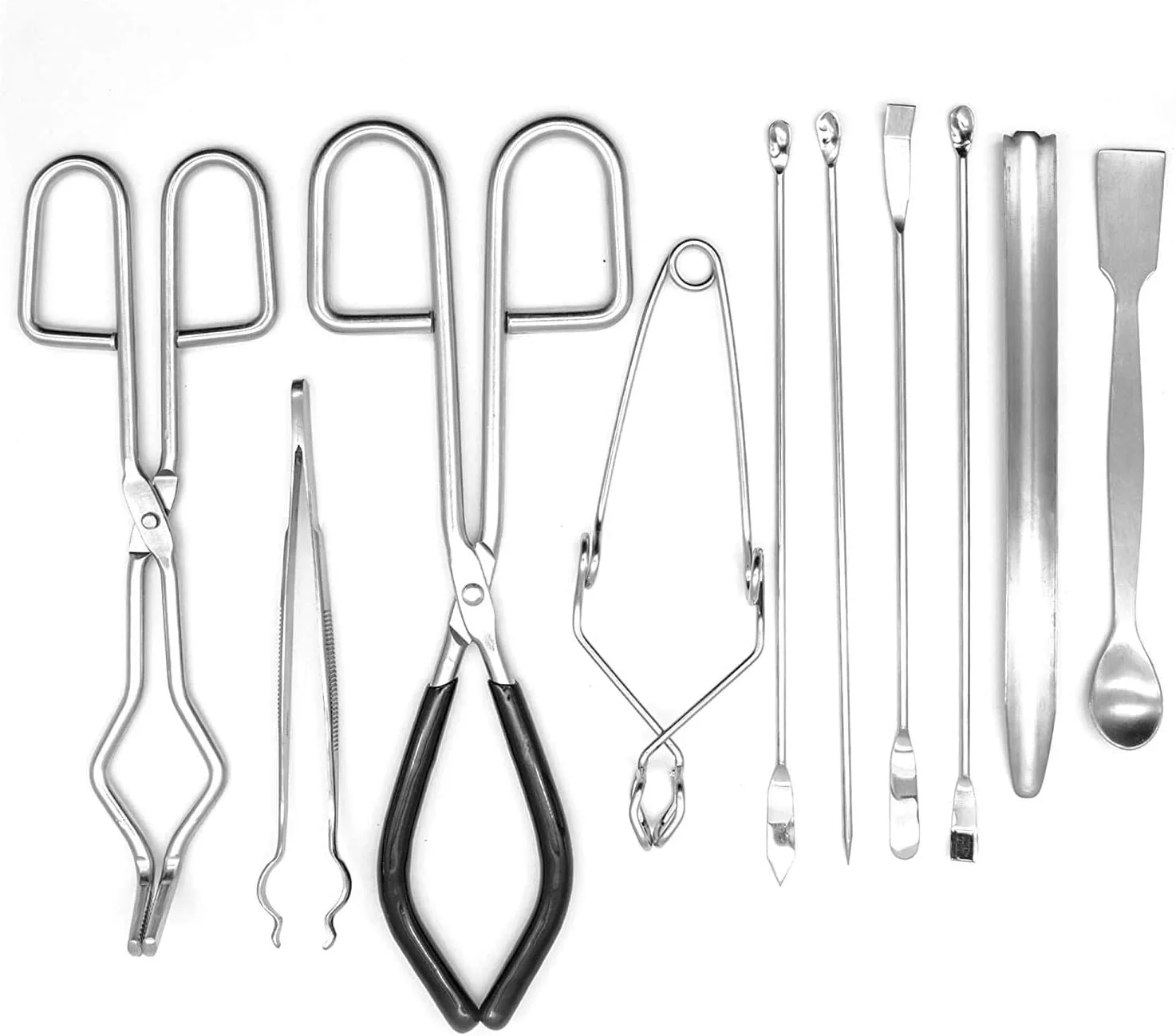

Types of Crucible Tongs and Their Functions

Crucible tongs are essential tools in laboratories where the handling of heated or fragile Crucibles is a regular occurrence. These tongs come in various designs, each tailored for specific functions and environments. The most common type is the standard crucible tongs, which typically feature a long handle with gripping ends designed to securely hold crucibles. These tongs are often made of metal, allowing them to withstand high temperatures without losing structural integrity. Their primary function is to safely lift and manipulate crucibles during heating or cooling processes, minimizing the risk of burns or spills.

Another popular variant is the spring-loaded crucible tongs, which employ a spring mechanism to provide a secure grip on the crucible. This design allows for easier handling, as the tongs automatically close around the crucible when pressure is applied. This feature is particularly useful in environments where quick movements are necessary, such as when transferring hot samples. Additionally, spring-loaded tongs often feature rubberized grips for better control, making them ideal for lab technicians who need to manage multiple tasks simultaneously.

For specialized applications, there are also ceramic crucible tongs, designed specifically for handling ceramic crucibles. These tongs are usually made from non-corrosive materials that can withstand the high temperatures associated with ceramic processing. Their design may include wider grips to accommodate the unique shape of ceramic crucibles, ensuring that they can be lifted without risk of damage. Furthermore, some tongs come with heat-resistant coatings, extending their lifespan and performance in high-temperature settings. Understanding the various types of crucible tongs available helps users select the right tool for their specific laboratory needs.

Materials Used for Crucible Tongs

When selecting crucible tongs, the material they are made from plays a crucial role in their effectiveness and durability.

Common materials used in the construction of crucible tongs include stainless steel, aluminum, tungsten, molybdenum, and heat-resistant plastics.

Stainless steel is the most prevalent choice due to its excellent heat resistance, strength, and durability. It can withstand extreme temperatures without warping or losing its grip, making it ideal for handling hot crucibles in a laboratory setting. Additionally, stainless steel tongs are generally easy to clean and maintain, contributing to their popularity among professionals.

Aluminum tongs are another option, known for their lightweight nature and good thermal conductivity. While they are less durable than stainless steel, they can be effective for specific tasks that require lighter handling. It is important to note, however, that aluminum may not withstand as high temperatures as stainless steel, which could limit its use in certain applications. Nonetheless, for those who prioritize ease of handling and weight, aluminum tongs can provide a practical solution in less demanding environments.

Heat-resistant plastics are evolving as a viable alternative for crucible tongs, particularly in settings where chemical resistance is also a concern. These materials can handle moderate temperatures and provide excellent grip, making them suitable for specific applications where metal tongs may corrode or react with substances being handled. However, users must ensure that the plastic can withstand the temperatures they plan to use it for, as not all plastics are created equal. Each material used in crucible tongs has its advantages and limitations, and understanding these can guide users in selecting the most appropriate tongs for their laboratory work.

For some extremely high temperature environment, tungsten and moly are considered as tongs material. In some occassions, expensive metal, such as platinum are used to cover the tips of the tongs.

Features to Consider When Choosing Crucible Tongs

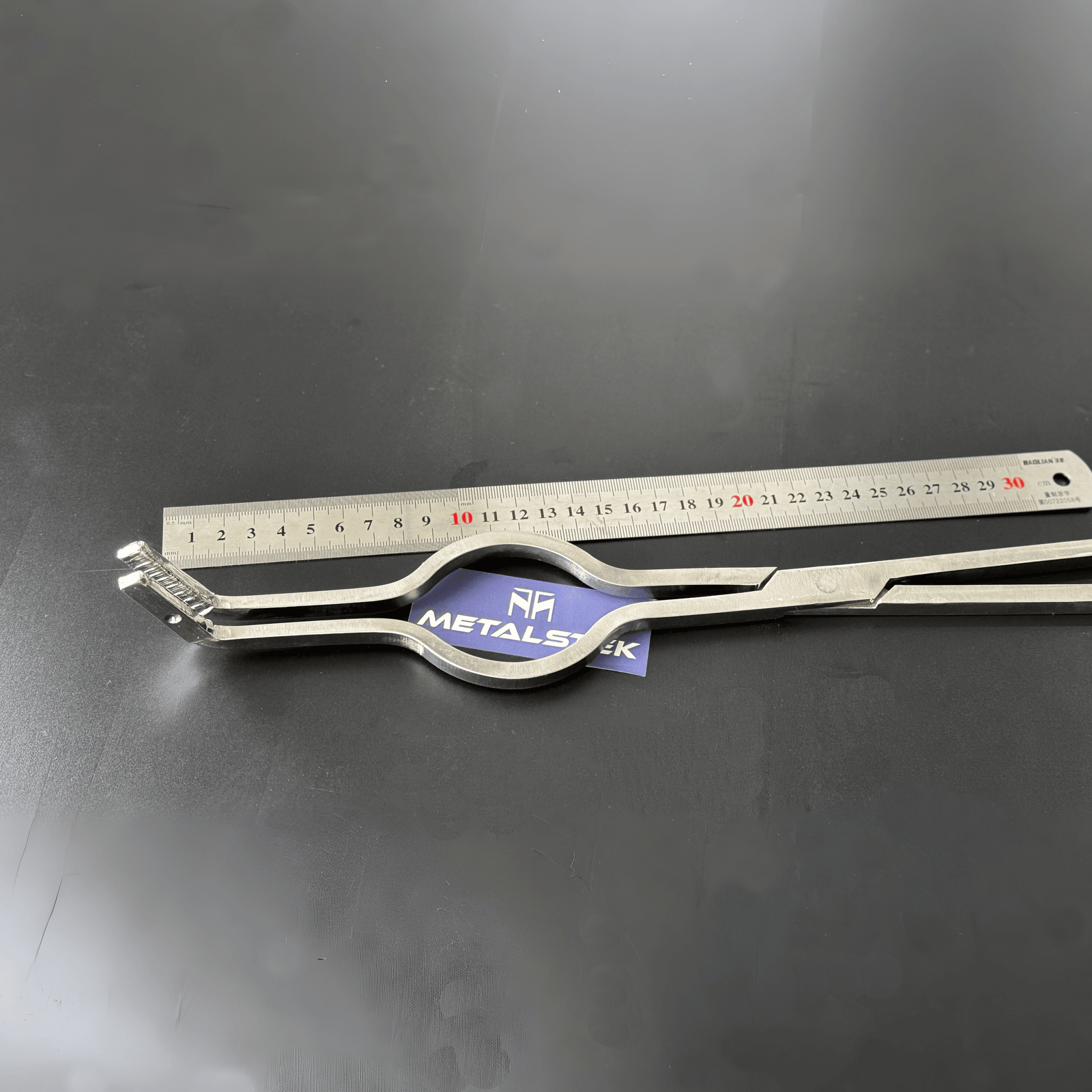

Choosing the right crucible tongs involves evaluating several key features that can significantly impact their usability and effectiveness. First and foremost, the length of the tongs is crucial. Longer tongs provide an extended reach, allowing users to handle hot crucibles from a safe distance, thus minimizing the risk of burns. Conversely, shorter tongs may offer better control in confined spaces but could expose the user to greater risk when handling heated materials. Therefore, it’s essential to consider the working environment and the typical sizes of crucibles being used to select the appropriate length.

Another important feature is the grip design of the tongs. Ergonomic grips enhance user comfort and control, especially during repetitive tasks. Some tongs come with rubberized or textured handles that provide a non-slip surface, reducing the likelihood of accidental drops or spills. Additionally, the design of the gripping ends is crucial; they should be shaped to securely hold the crucible without damaging it. Tongs with curved or serrated ends can offer improved stability, ensuring that the crucible is held firmly, even during movement.

Lastly, the weight of the tongs should not be overlooked. Lightweight tongs can reduce user fatigue, especially during extended periods of use. However, they should still be sturdy enough to handle the crucible securely. It’s a balancing act between weight and strength; thus, selecting tongs that feel comfortable and manageable in hand is vital. By considering these features—length, grip design, and weight—users can make informed decisions when selecting the perfect crucible tongs for their laboratory applications.

Proper Usage and Handling of Crucible Tongs

Utilizing crucible tongs properly is essential for ensuring safety and efficiency in the laboratory. When handling hot crucibles, it is crucial to approach the task with caution. First, always ensure that the tongs are clean and free of debris before use. This prevents any unwanted reactions between residues and the materials being handled. When lifting a crucible, grip it firmly with the tongs, ensuring that the ends are securely positioned around the crucible. This will help prevent slipping or dropping, which could lead to spills or breakage.

When transferring a crucible from one location to another, maintain a steady and controlled movement. Avoid sudden jerks or movements that could destabilize the crucible. It’s best to carry the crucible at waist height to ensure better control and visibility. Always keep an eye on the crucible and its contents, especially if they are in a liquid state, to prevent splashing. Lastly, when placing the crucible down, do so gently to avoid stress on the material, which could result in cracking or shattering.

Another key aspect of proper handling is awareness of the surroundings. Ensure that the workspace is organized and free from clutter, allowing for safe movement while carrying hot materials. Be mindful of other individuals in the vicinity to avoid accidental contact or collision. Use the tongs in conjunction with proper personal protective equipment, such as heat-resistant gloves and goggles, to enhance safety while performing laboratory tasks. By adhering to these guidelines for proper usage and handling, users can significantly reduce the risks associated with working with crucibles in the lab.

Safety Precautions When Using Crucible Tongs

Safety is paramount when working with crucible tongs, particularly in environments dealing with high temperatures or hazardous materials. One of the most fundamental precautions is to wear appropriate personal protective equipment (PPE). This includes heat-resistant gloves to protect hands from burns, safety goggles to shield eyes from splashes or debris, and lab coats to prevent exposure to chemical substances. By prioritizing PPE, users can create a safer working environment while handling hot materials.

It is also crucial to be aware of the limitations of the tongs you are using. Each set of tongs has a designated temperature threshold; exceeding this limit can lead to tool failure or diminished effectiveness. Always consult the manufacturer’s specifications to ensure that the tongs are suitable for the temperatures and materials being handled. This attention to detail helps prevent accidents and ensures that tools are used within their operational parameters.

Furthermore, proper storage and maintenance of crucible tongs play a significant role in safety. After use, tongs should be cleaned and inspected for any signs of damage or wear. Any tongs showing signs of corrosion, bending, or cracking should be replaced immediately to prevent accidents during future use. Storing tongs in a designated area, away from high-traffic locations, can also prevent accidental injury. By following these safety precautions, users can significantly enhance their safety while working with crucible tongs in the laboratory.

Maintenance and Care of Crucible Tongs

To ensure the longevity and effectiveness of crucible tongs, proper maintenance and care are essential. After each use, it is important to clean the tongs thoroughly. Residues from materials handled can accumulate on the surface, potentially affecting future performance. A gentle wash with warm soapy water, followed by a thorough rinse, is usually sufficient. For stainless steel tongs, a soft cloth can be used to remove any stubborn residues, ensuring that the tongs remain in pristine condition. Avoid abrasive cleaners that could scratch or damage the surface.

Regular inspections are also vital for maintaining the integrity of crucible tongs. Users should check for signs of wear, such as bent arms, weakened grips, or corrosion. If any issues are detected, it is best to replace the tongs rather than risk using damaged equipment. Keeping a maintenance log can be beneficial, allowing users to track the condition of their tools and know when replacements are needed.

Additionally, proper storage is a crucial aspect of care. Tongs should be stored in a dry, cool place to prevent rust and deterioration. Using a designated holder or rack can keep them organized and prevent accidental damage. When storing, ensure that the tongs are not in a position where they can be knocked over or bumped, which can lead to misalignment or breakage. By adhering to these maintenance and care guidelines, users can extend the lifespan of their crucible tongs and ensure they remain a reliable tool in the laboratory.

MetalsTek and Our Crucible Tongs: Crafting Precision for Your Lab Needs

At MetalsTek, we understand the critical role that reliable tools play in laboratory success. Crucible tongs, in particular, are indispensable for safely and effectively handling high-temperature crucibles in chemistry, metallurgy, and material science applications. With our expertise in advanced materials and engineering, we’ve crafted a line of crucible tongs designed to meet the diverse needs of labs around the globe.

Our tongs are built with durability, precision, and versatility in mind. Whether you require stainless steel for corrosion resistance or specialized alloys for extreme temperature tolerance, MetalsTek ensures that our tongs deliver consistent performance. The ergonomic designs enhance user safety and efficiency, minimizing the risks associated with handling hot or fragile crucibles.

When you choose MetalsTek crucible tongs, you’re not just investing in a product—you’re investing in a commitment to quality, innovation, and customer satisfaction. From seasoned professionals to students mastering the basics, our tongs are trusted by those who demand the best in their lab equipment.

Conclusion and Final Thoughts

To sum up, crucible tongs are indispensable tools in any laboratory setting where the handling of hot materials is a routine task. Understanding the different types available, the materials used, and the features to consider can significantly impact your efficiency and safety while working. Proper usage, safety precautions, and regular maintenance are vital for ensuring that these tools remain functional and reliable over time.

As you explore the options available for purchasing crucible tongs, consider your specific laboratory needs, including the types of crucibles you handle and the typical temperatures involved. Whether you prioritize lightweight designs, ergonomic grips, or specialized materials, there is a pair of tongs out there that will suit your requirements perfectly.

With the right knowledge and tools, you can confidently handle crucibles, enhancing your laboratory experience. We hope this guide has provided you with valuable insights into selecting, using, and caring for crucible tongs, empowering you to make informed decisions in your scientific endeavors.

One Reply to “Unlocking the Secrets to Safe and Efficient Handling: A Comprehensive Guide to Crucible Tongs by MetalsTek Engineering”

Hey very interesting blog!