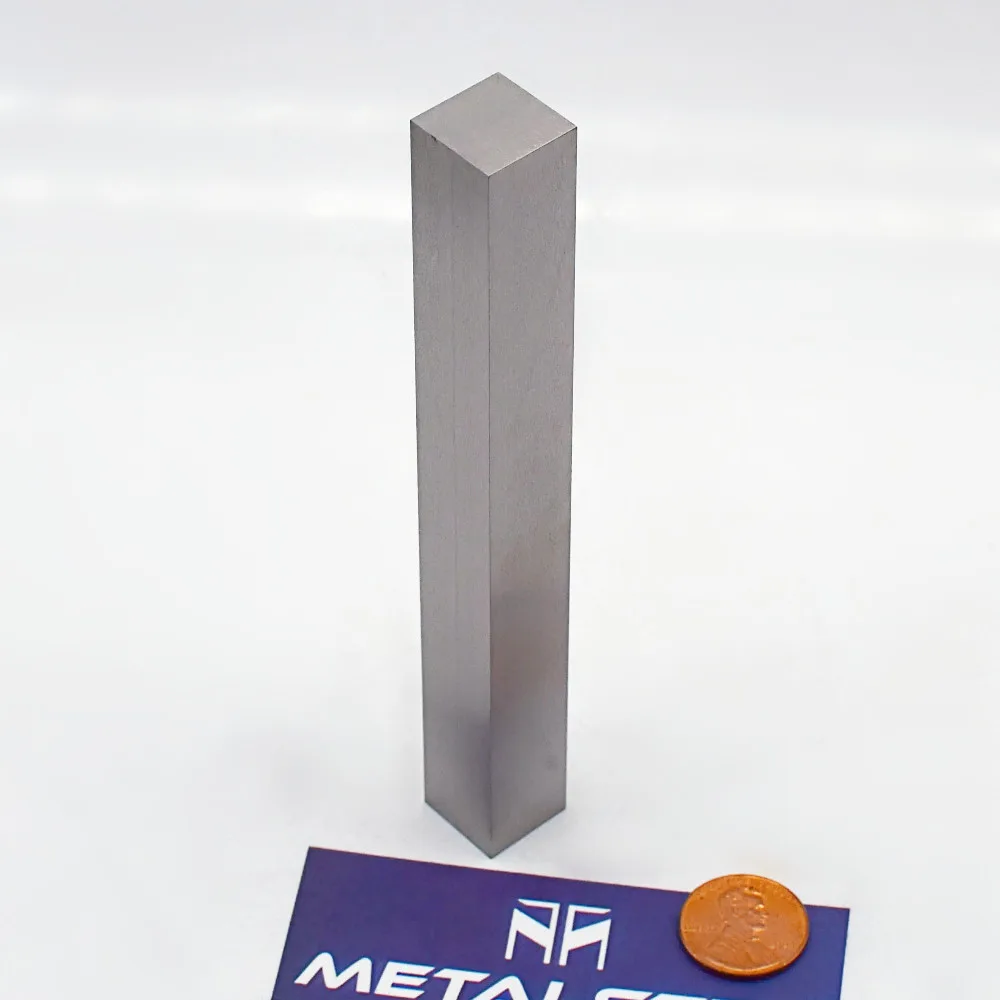

When it comes to high-performance environments—where failure isn’t an option—engineers turn to rare, powerful materials that can go the distance. Think aerospace turbines, high-vacuum chambers, or advanced microelectronics. In these scenarios, conventional alloys just don’t cut it. That’s where Hafnium-Tantalum (Hf-Ta) alloy bars step in. But here’s the kicker: making them at a precise 73:27 wt% ratio without cracks is a manufacturing feat most suppliers can’t pull off. At MetalsTek, we’ve cracked the code—literally and figuratively—and now offer Hf-Ta alloy bars with zero defects and 99.99% purity.

What Makes the 73:27 Hf-Ta Alloy So Challenging Yet Valuable?

This particular composition isn’t arbitrary. The 73:27 weight ratio of Hafnium to Tantalum blends the best of both elements—hafnium’s high thermal stability and neutron absorption, with tantalum’s ductility and extreme corrosion resistance. The result? A superalloy bar capable of maintaining structural integrity at temperatures above 2400°C and in chemically hostile environments. However, this exact ratio presents one major obstacle: it often leads to internal stress fractures during cooling, especially when purity is kept high.

That’s where MetalsTek steps up. Through proprietary process control and post-treatment techniques, we’ve eliminated internal cracking and now manufacture these alloy bars with absolute consistency—whether you need them for lab-scale experimentation or full-scale industrial deployment.

The Science Behind the Strength

Let’s dig a little deeper. Hafnium (Hf), with a melting point of 2,227°C and a density of 13.3 g/cc, offers unmatched resistance to corrosion, especially from aggressive halogens. It’s a favorite in nuclear applications due to its neutron-capture properties.

Tantalum (Ta), meanwhile, melts at 3,017°C and is known for maintaining mechanical strength under intense heat, making it a go-to in electronics and aerospace components.

By alloying the two, you get an exotic blend ideal for:

- Rocket nozzle linings and heat shields

- Semiconductor chamber linings

- High-temperature crucibles and thin-film deposition

- Neutron-absorbing control components in nuclear reactors

Why Defect-Free Matters

Most cracking in Hf-Ta bars happens due to the mismatch in crystal structure and cooling rates during solidification. In many production environments, even minor inconsistencies can lead to microfractures, rendering the material unusable for precision applications.

At MetalsTek, we control every stage—from vacuum arc melting to forging and final machining—under tightly regulated conditions. Our custom-built sintering and annealing methods prevent residual stress accumulation, resulting in bars that are structurally flawless and visually uniform.

MetalsTek: Your Partner in Custom Alloys

Whether you’re sourcing a single rod for academic R&D or high-volume orders for commercial production, MetalsTek offers unmatched flexibility:

- Custom shapes, diameters, and lengths

- Precision cuts to your drawing or specs

- Quick turnaround and global delivery

- ISO9001-certified production with full traceability

With over a decade in the refractory and rare metal industry, we understand what our clients—from NASA engineers to semiconductor fabs—demand: reliability, technical expertise, and materials that simply perform.

Conclusion: Let’s Build Something Breakthrough

If you’re pushing the limits of temperature, pressure, or reactivity, don’t settle for off-the-shelf alloys. Our Hf-Ta bars at 73:27 wt% are engineered for your extremes—without the compromise of defects or delays.

📩 Contact us at sales@metalstek.com

🌐 Explore more: www.metalstek.com

People Also Ask (FAQs)

1. What is Hafnium-Tantalum alloy used for?

Hafnium-Tantalum alloys are used in aerospace, nuclear reactors, semiconductor deposition chambers, and other high-temperature or corrosive environments. They are valued for their stability, thermal resistance, and ability to perform under extreme stress.

2. Why is the 73:27 Hf-Ta ratio significant?

The 73:27 weight ratio offers a unique synergy of hafnium’s thermal and chemical stability with tantalum’s ductility and corrosion resistance. This composition is optimized for structural performance at ultra-high temperatures.

3. What are the challenges in manufacturing Hf-Ta alloys?

Due to the different thermal expansion rates and atomic structures of hafnium and tantalum, alloys in this ratio are prone to cracking during cooling and forging. Precision control in processing is required to achieve defect-free results.

4. Can I order custom Hf-Ta alloy bars in different dimensions or purities?

Yes. MetalsTek specializes in custom refractory alloys, including Hf-Ta. Customers can request specific shapes, dimensions, tolerances, and purity levels (typically up to 99.99%).

5. Is Hf-Ta alloy safe for use in nuclear applications?

Yes. Hafnium’s strong neutron absorption makes it particularly useful in nuclear control rods and shielding. When alloyed with tantalum, it remains stable and effective in radiation-intensive environments.

6. What industries most commonly use Hf-Ta alloy bars?

Common industries include aerospace (for rocket components), semiconductors (for chamber linings), nuclear power, R&D labs, and any field requiring extreme temperature or corrosion resistance.

7. How long is the lead time for custom Hf-Ta alloy orders?

Lead times vary by spec and quantity, but MetalsTek typically offers short turnaround cycles compared to industry averages—often with expedited options available.