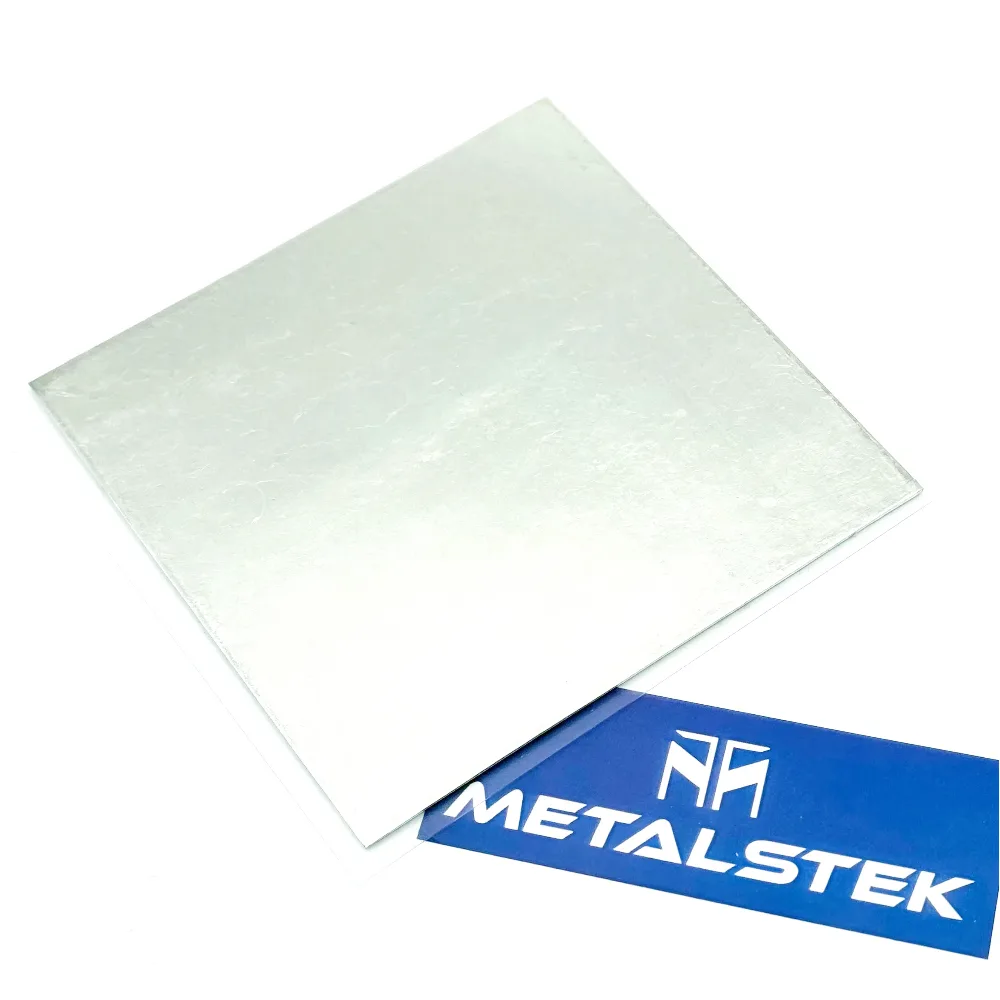

If you need indium foil that offers excellent thermal conductivity, malleability, and integrity under demanding conditions, our high-purity indium sheets (0.1 mm up to 3 mm) deliver. At MetalsTek, we provide custom-cut indium foil and sheet to precise tolerances, ideal for thermal interface, vacuum sealing, bonding, and electronics uses.

Indium remains one of the most versatile metals for thermal management and sealing applications. Its softness allows conformal contact, and its relatively low melting point (~156.6 °C) makes it ideal for bonding and gasket applications without damaging nearby components.

Key Features & Technical Details

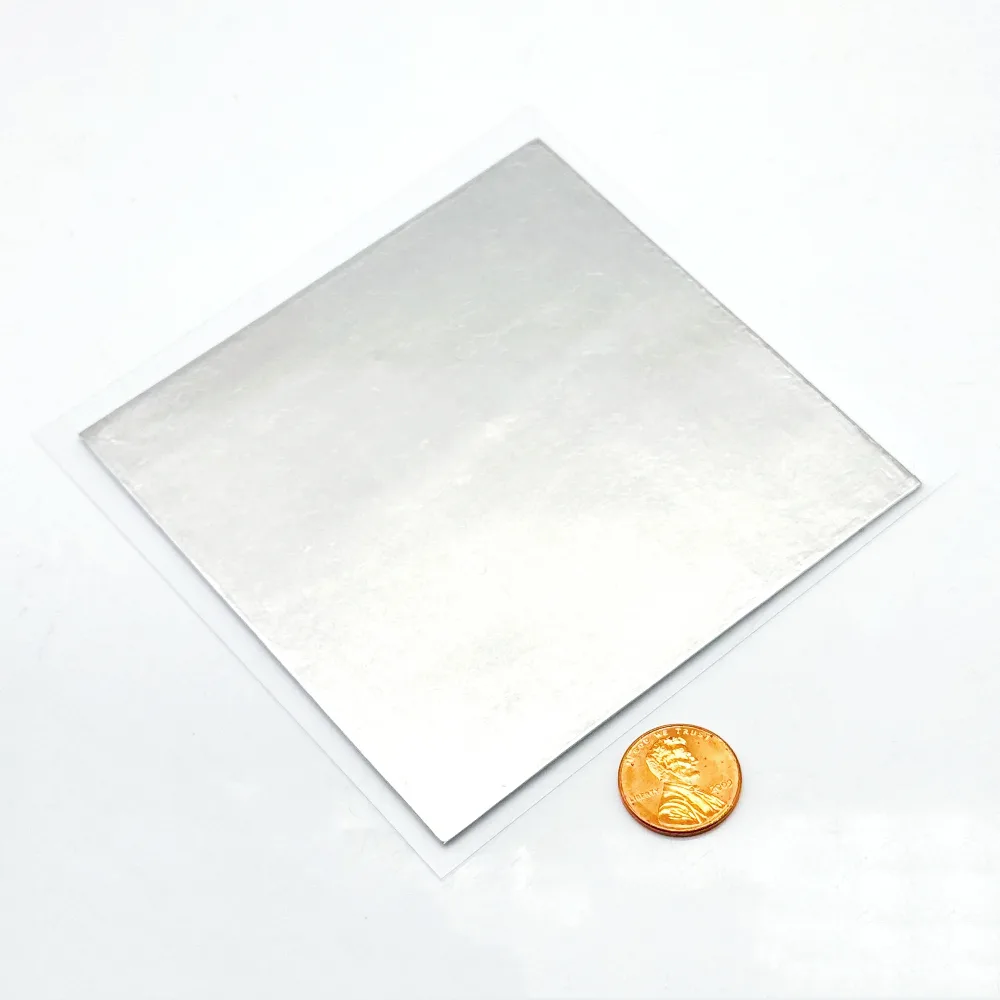

- Thickness Range & Tolerances: We supply indium foil and sheet from 0.1 mm up to 3 mm. For thin foils (below ~0.5 mm) tighter tolerances are standard.

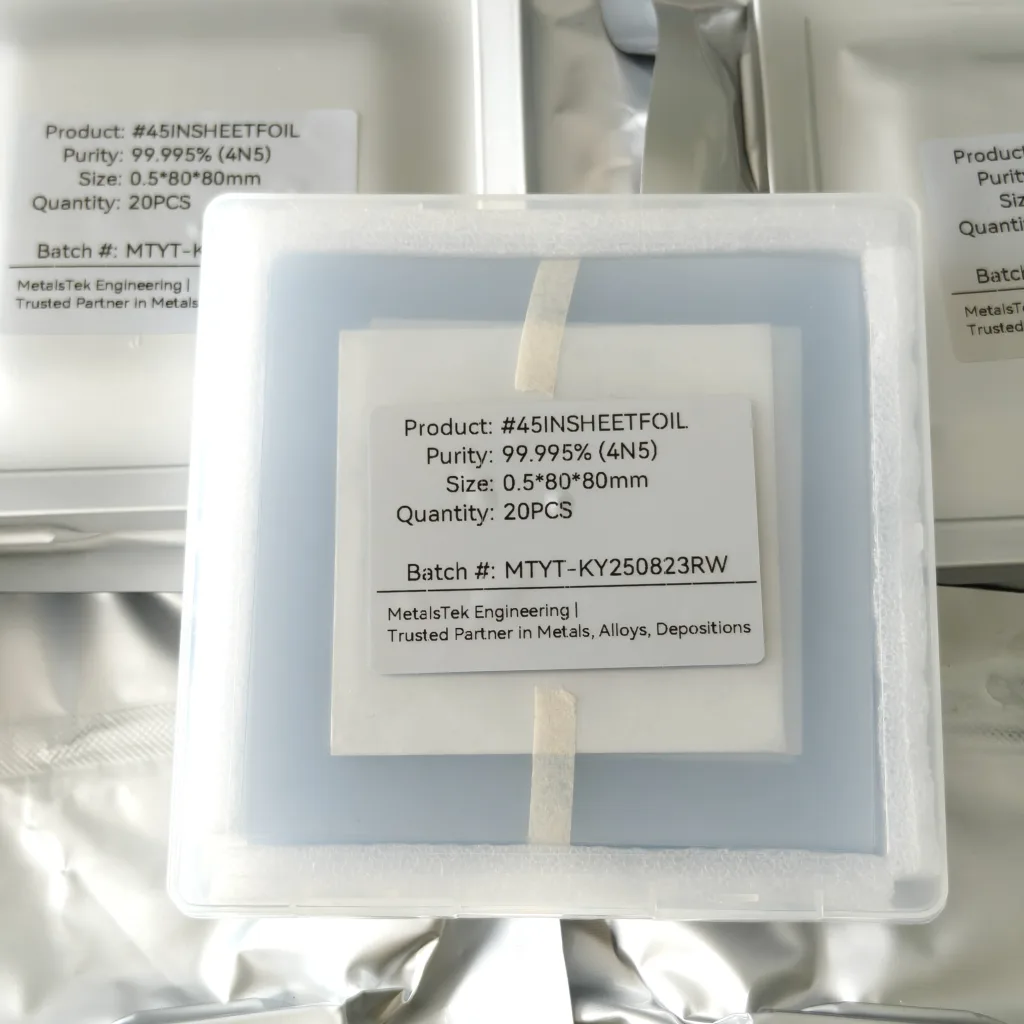

- Purity Options: From 99.9 % up to 99.999 % (or higher upon request).

- Mechanical Properties: Indium is extremely soft, ductile, and deformable — perfect for creating full-surface contact under compression.

- Thermal & Electrical Conductivity: Excellent for heat spreading and interface layers.

- Melting & Phase Behavior: Melting point ~156.6 °C.

- Packaging & Handling: Due to its softness, sheets are packaged to avoid deformation, often in vacuum-sealed or inert atmosphere bags.

Applications & Use Cases

- Thermal interface layers: Between heatsinks, power modules, and substrates.

- Vacuum seals / gaskets: Because it can cold-weld and fill microscopic gaps.

- Bonding & cold soldering: Especially where low-temperature joins are needed.

- Cryogenic and low-temperature systems: Indium remains soft and conformal even at very low temperatures.

- Electronics / microelectronics: As soft interlayers or stress-relief layers in devices.

Best Practices & Processing Notes

- Cutting & handling: Use sharp blades or shears; support the sheet to avoid bending or wrinkling.

- Deformation / molding: Because indium is soft, it can be cold-pressed or molded into fine shapes.

- Surface preparation: Clean surfaces before bonding to ensure good contact; remove oxides or contaminants.

- Assembly / compression: Use controlled pressure for conformal contact; avoid excessive force causing extrusion.

- Thermal cycling: Indium performs well under cycles due to its ductility, but gradual temperature changes help avoid stress.

You May Also Want to Know

1. What purity levels are available for indium foil and sheet?

Typical grades range from 99.9 % to 99.999 % or higher, depending on the application’s sensitivity to trace contamination.

2. How thin can indium foil be made?

We offer down to 0.1 mm (100 µm) and can even go thinner in special cases for micro‑applications.

3. How thick can the sheet go?

Up to 3 mm in sheet form is standard. For thicker forms, we treat them more like plates or blocks.

4. What dimensions (width/length) are typical?

Depending on sheet size, widths of several hundred millimeters are common. We cut to customer-required lengths.

5. What tolerances can be held?

Thinner foils have tighter tolerances; thicker sheets may allow ±0.01 mm or more, depending on size.

6. What are the mechanical properties of indium?

It’s very soft and highly ductile, capable of large plastic deformation at low stress.

7. What is the melting point of indium?

Approximately 156.6 °C.

8. What is the density and thermal conductivity?

Density is ~7.31 g/cm³. Its thermal conductivity is relatively high for interface materials.

9. Why is indium used as a thermal interface material?

Because its softness allows it to conform to surface roughness and fill microscopic gaps, reducing thermal resistance.

10. How is indium foil packaged and shipped?

Foil sheets are vacuum-sealed or packed in an inert atmosphere. For very thin foils, extra care is taken to avoid bending or damage.

11. What is the lead time for custom sheets?

Typically a few weeks depending on thickness, dimensions, and purity.

12. Can indium sheets be bonded to other metals?

Yes — its softness and low melting point allow for cold bonding, clamping, or diffusion bonding with compatible metals.

13. How to avoid contamination or oxidation?

Store in sealed environment, use clean tools, and minimize exposure to air or moisture.

14. What failure modes are common?

Tearing, wrinkling, voids in bonding, extruding under pressure, or oxidation-related degradation.

15. Is indium reactive or hazardous?

Indium is relatively stable in air, but fine particulates or dust should be handled with standard safety precautions.

16. Can we supply custom thickness or geometric shapes?

Yes — we can tailor sheet shapes, cutouts, and thicknesses to your drawings.

17. What applications use thick indium sheet (>1 mm)?

Thicker sheets are used where structural strength is needed, or as sacrificial interlayers in assemblies.

18. How does thermal cycling affect indium sheet?

Thanks to its ductility, indium can tolerate many thermal cycles, but sudden temperature gradients should be avoided.

19. What is the cost driver for thicker sheets?

Material cost and machining/rolling complexity increase with thickness, especially beyond standard ranges.