Strontium (Sr), Barium (Ba), and Gadolinium (Gd) sputtering targets play critical roles in advanced materials, from oxide films to magnetic and optical coatings. At MetalsTek, we deliver high‑density, high‑purity Sr, Ba, and Gd targets—customized to your dimensions, bonding needs, and application demands.

Our targets are engineered to offer uniform erosion, minimal particle generation, and stable performance over long runs. Whether you’re developing oxide heterostructures, rare earth doped layers, photonics, or magnetic thin films, our Sr, Ba, and Gd targets provide reliable materials for your deposition processes.

Key Features & Custom Options

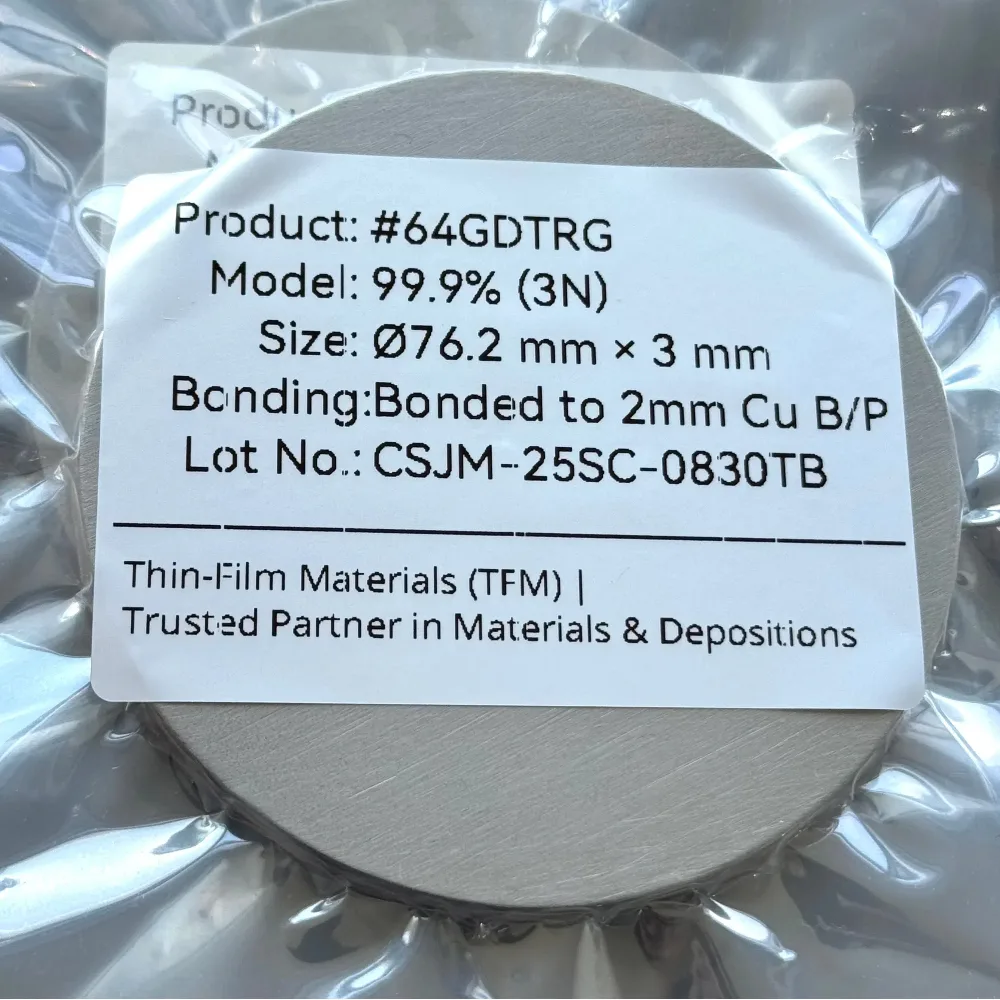

- Purity options: Typically from 99.9% up to 99.999%, depending on your device demands.

- Shapes & sizes: Discs, rectangular plates, annular, step, or other custom geometries.

- Bonding options: Direct mounting, indium bonding, elastomer layers, or backing plates (Cu, Mo, etc.).

- Microstructure & density: Fully densified material, fine grain structure, minimal porosity to reduce defect risks.

- Packaging: Inert or vacuum sealed to prevent oxidation during storage and transport.

Application Areas & Material Advantages

- Strontium (Sr): Used in perovskite oxides, ferroelectric films, oxide electronics, barrier layers, and dielectric structures.

- Barium (Ba): Essential in Ba-based oxides (such as BaTiO₃, BaZrO₃) for dielectric, ferroelectric, and piezoelectric thin films.

- Gadolinium (Gd): Useful for magnetic thin films, rare-earth garnet films, and as dopants in optical or microwave devices.

These metals, when used as pure or alloy/oxide sputtering targets, contribute to high-performance films in electronics, photonics, and advanced materials research.

Typical Specifications (Indicative)

| Material | Typical Density | Melting Point / Thermal Traits | Common Sizes & Forms | Notes |

|---|---|---|---|---|

| Sr | ~2.64 g/cm³ (metallic Sr) | Relatively low melting compared to others | Discs, plates | needs careful oxidation protection |

| Ba | ~3.51 g/cm³ | Reactive metal, moderate melting point | Various shapes, often used as Ba oxide or compounds | Likely used in oxide form |

| Gd | ~7.9 g/cm³ | Melting ~1,313 °C, moderate thermal conductivity | Ø2″ to Ø6″, plates, custom shapes | Suitable for magnetic / rare earth uses |

Because pure Sr and Ba are reactive metals, many sputtering targets use oxide or compound forms to stabilize behavior during deposition.

Packaging:

Strontium and barium sputtering targets are highly reactive and are packaged under protective oil to prevent oxidation during storage and transit. Gadolinium targets, being more stable, are typically vacuum-sealed or packed in inert gas environments. All materials are securely cushioned to prevent mechanical damage.

Work With MetalsTek for Your Custom Sr, Ba & Gd Targets

Tell us your required purity, shape, size, bonding needs, or application context—whether for ferroelectric stacks, oxide heterostructures, magnetic layers or specialty optics. We’ll respond with a tailored solution and quotation that fits your project needs.

You May Also Want to Know

1. What is a strontium sputtering target?

A strontium sputtering target is a high-purity source of strontium metal or compound used in physical vapor deposition systems. It is commonly used to deposit thin films for electronic, optical, or ceramic applications, often in the form of complex oxides.

2. What purity grades are offered for Sr, Ba, and Gd targets?

Typical purity levels range from 99.9% (3N) to 99.999% (5N), depending on the application’s sensitivity to contamination. High-purity grades are commonly used in semiconductor, research, and advanced coating industries.

3. Which shapes and thicknesses are common for these targets?

These targets are available as circular discs, rectangular plates, annular rings, or custom designs. Standard thicknesses range from 1 mm to over 10 mm, depending on the sputtering system and application.

4. What bonding methods are used for Sr, Ba, and Gd targets?

Bonding options include indium bonding, elastomeric layers, or direct bonding onto backing plates made of copper, molybdenum, or other heat-conductive metals. Bonding improves thermal management and target stability during use.

5. How are these metals typically packaged to avoid oxidation?

Strontium and barium targets are packed under protective oil to shield them from air and moisture due to their high reactivity. Gadolinium targets, which are more stable, are vacuum-sealed or stored in inert atmospheres.

6. What deposition techniques work best with Sr, Ba, or Gd targets?

These targets are typically used in RF magnetron sputtering, pulsed DC sputtering, or reactive sputtering setups. The technique depends on the material conductivity and desired film properties.

7. Why are oxide or compound targets sometimes preferred over pure metals?

Oxide or compound targets are more stable during deposition and help achieve better stoichiometry in complex film systems, especially for materials like barium titanate or strontium zirconate.

8. How does target density and microstructure affect film quality and defect rate?

Higher density and fine-grain microstructure reduce the risk of particle generation and improve uniform film deposition, leading to better electrical and optical performance in thin films.

9. What are typical application areas for Sr, Ba and Gd-based films?

Common applications include ferroelectric and piezoelectric devices, dielectric layers, magnetic coatings, optical filters, memory devices, and oxide semiconductors.

10. How to handle and store reactive metal targets like Sr or Ba?

Always handle these targets in inert atmospheres or gloveboxes when possible. Store them in original sealed containers and avoid exposure to air, moisture, or acids.

11. What ramp‑up / ramp‑down practices help avoid target damage?

Start with low sputtering power and gradually increase to full operational power to reduce thermal shock. Allow slow cool-down before venting the chamber to avoid cracking or delamination.

12. What is a realistic lead time for custom Sr, Ba or Gd targets?

Lead times typically range from 2 to 6 weeks depending on the complexity, size, bonding requirements, and current production load.

13. Can Sr, Ba, or Gd targets be alloyed or doped?

Yes, these materials can be tailored with dopants or alloying elements to achieve specific film properties such as magnetism, conductivity, or dielectric behavior.

14. How is purity verified in these rare-metal targets?

Purity is usually confirmed through methods like GDMS (Glow Discharge Mass Spectrometry), ICP-MS, or XRF, depending on the element and required trace-level sensitivity.

15. What are common failure modes for Sr, Ba, and Gd targets?

Potential issues include oxidation (for Sr and Ba), cracking due to thermal stress, bonding failure, and particle formation from surface imperfections.

16. Can customers perform their own bonding to backing plates?

Yes, but it requires careful thermal and mechanical matching. Improper bonding may result in heat transfer problems or target delamination during use.

17. How to avoid contamination or particle generation during deposition?

Use high-density, defect-free targets and ensure a clean chamber environment. Gradual power ramp-up also helps minimize flaking or arcing.

18. Are there safety concerns in handling these rare-earth or reactive metals?

Yes. Strontium and barium are highly reactive and must be kept away from water and air. Gadolinium is less reactive but should still be handled with gloves and proper ventilation.