Introduction: Why Understanding Molybdenum Grades Matters

If you’ve ever tried to order molybdenum and felt like you were reading a secret code—Mo-1, Mo-2, TZM, Mo-La—you’re not alone. These grades and variants can be confusing, especially when you’re balancing performance, cost, and application-specific demands. Whether you’re in aerospace, semiconductors, or research, choosing the right molybdenum type is critical to performance and cost-efficiency.

This article breaks down the differences, relationships, and best-use scenarios for molybdenum, Moly, TZM alloy, Mo-1, and Mo-2, plus other common variants to help you make informed sourcing decisions.

Answering the Big Question: What’s the Difference?

“Moly” is shorthand for molybdenum, a refractory metal known for its high melting point (2623°C), thermal conductivity, and corrosion resistance. But not all molybdenum is created equal. Here’s a quick overview:

| Grade/Alloy | Purity (%) | Key Components | Typical Applications |

|---|---|---|---|

| Mo-1 | ≥99.95 | Pure Mo | Semiconductors, high-vacuum, optics |

| Mo-2 | ≥99.90 | Pure Mo | Structural parts, general industry |

| TZM | ~99.2 | Mo + Ti + Zr + C | Aerospace, dies, high-temp tools |

Deep Dive: Mo-1 vs. Mo-2 vs. TZM

Mo-1 Grade

- Purity: ≥99.95%

- Applications: Semiconductor, medical imaging, high-vacuum systems

- Key Benefits: High purity, low contamination risk

Mo-2 Grade

- Purity: ≥99.90%

- Applications: Industrial parts, furnace components, general machining

- Key Benefits: Cost-effective for non-sensitive applications

TZM Alloy

- Composition: Mo + ~0.5% Ti + ~0.08% Zr + ~0.02% C

- Applications: Die casting, aerospace, high-temp tooling

- Key Benefits: High creep strength, higher recrystallization temperature

More Than Just Mo: Other Molybdenum Variants Explained

| Variant | Key Feature | Main Applications |

| Mo-La | Lanthanum-doped, high temp resistance | Aerospace, reactors |

| Mo-Cu | Good thermal conductivity | Electronics, radar systems |

| Mo-Re | High ductility and strength | Thermocouples, propulsion |

| Mo-W | High hardness and strength | Nuclear, lamps |

| MoSi2 | Excellent oxidation resistance | Furnace elements |

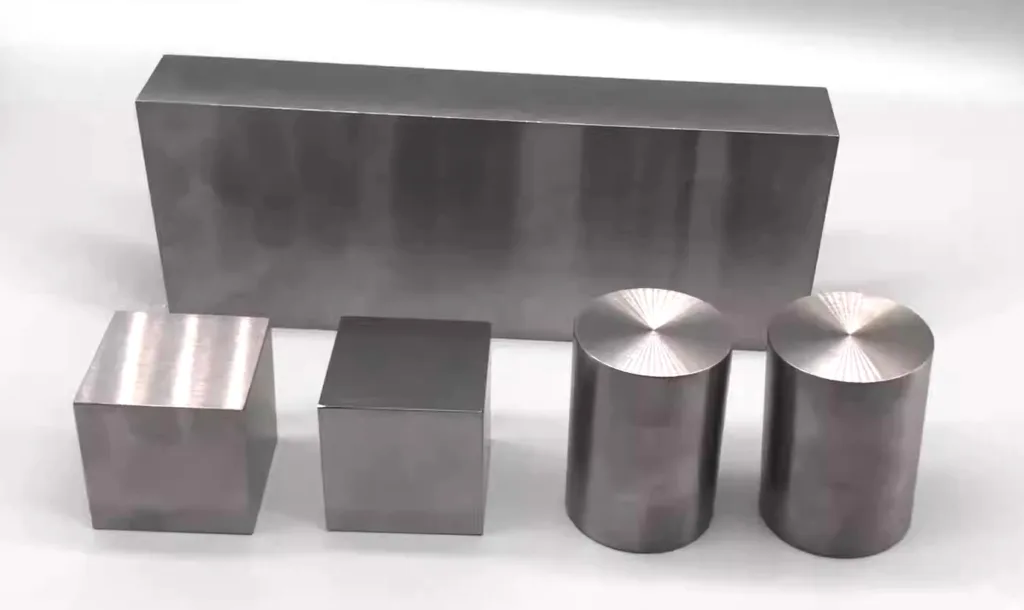

- Sintered: Ideal for shaped parts (boats, crucibles)

- Forged: Higher mechanical strength (rods, fasteners)

Sintered vs. Forged Mo

Application Matching: Which Molybdenum is Right for You?

- Semiconductors & Electronics: Mo-1, Mo-Cu, Mo-Re

- Aerospace: TZM, Mo-La, Mo-Re

- Furnace & Thermal Components: Mo-2, Mo-W, MoSi2

- Medical Imaging & Devices: Mo-1, Mo-La

- High-Temp Tooling & Dies: TZM, Mo-W

- Research & Custom Alloys: Mo-Re, Sintered or Forged Mo

MetalsTek Tips: How to Choose the Right Grade

- Purity Needs: Choose Mo-1 for sensitive applications like semiconductors.

- Strength & Temp Resistance: Use TZM or Mo-La when operating near molybdenum’s thermal limits.

- Budget Considerations: Mo-2 offers reliability at a better price for non-critical uses.

- Custom Requirements: Discuss with your supplier about sintered or forged forms, or alloys like Mo-Cu and Mo-Re for specialized needs.

Working with a reliable OEM like MetalsTek ensures your specifications are met with consistent quality and delivery.

Conclusion: Simplifying Your Material Decisions

Molybdenum and its alloys cover a broad spectrum of industrial and scientific needs. By understanding the differences among Mo-1, Mo-2, TZM, and other variants, you can better align your material choices with your project demands. This not only saves money but ensures performance and reliability.

You May Also Want to Know

1. What is molybdenum and why is it important?

Molybdenum (Mo, atomic number 42) is a refractory metal known for its high melting point (~2623 °C), strength at elevated temperatures, and corrosion resistance. It’s essential in industry—used in alloys and electronics—and in biology as a trace mineral supporting enzymes involved in protein, sulfur, and toxin metabolism.

2. What are the common grades of industrial molybdenum?

Common grades include Mo‑1 (≥99.95% purity), Mo‑2 (≥99.90% purity), and TZM alloy (Mo with ~0.5% Ti and ~0.08% Zr). Each grade offers different levels of purity, strength, and cost tailored to specific industrial applications.

3. When should I use TZM instead of pure molybdenum?

TZM is preferred for high-temperature applications (700–1400 °C) due to its enhanced strength, creep resistance, and reduced embrittlement compared to pure moly.

4. What are Mo‑La, Mo‑Cu, Mo‑Re, Mo‑W, and MoSi₂ alloys?

These are specialized molybdenum variants:

- Mo‑La: With lanthanum to improve creep resistance.

- Mo‑Cu: For heat sinks and low thermal expansion.

- Mo‑Re: With rhenium for ductility and high-temperature strength.

- Mo‑W: For hardness and molten metal resistance.

- MoSi₂: A ceramic compound for furnace heating elements.

5. What are the main uses of molybdenum?

- Alloys: Strengthen steel, aerospace, and defense parts

- Electronics: Sputtering targets, semiconductor base plates

- High‑temperature equipment: Furnace elements, die-casting machinery

- Medical: X-ray targets and imaging devices

6. How much molybdenum do people need in their diet?

Adults need about 45 µg/day, with elevated needs (50 µg/day) during pregnancy or lactation. Infants and children require smaller amounts.

7. What are common dietary sources of molybdenum?

Good sources include legumes, whole grains, organ meats, dairy, nuts, and leafy vegetables

8. Can you take too much molybdenum?

High intakes (e.g., >10 mg/day) may lead to gout, diarrhea, and copper deficiency. Toxicity is rare but may occur with supplementation or occupational exposure

9. How does the body use molybdenum biologically?

It’s a cofactor for enzymes like sulfite oxidase and xanthine oxidase—essential in sulfur amino acid metabolism and toxin breakdown. Molybdenum deficiency affects these pathways

10. Does molybdenum deficiency occur?

It’s rare. When it happens—typically in specialized medical scenarios—it can cause neurological issues due to enzyme inactivity. Restoration usually involves supplementation of ~300 µg/day .

Need help deciding between Mo-1 and TZM? Have a custom alloy requirement? Contact our team at sales@metalstek.com or request a quote at www.metalstek.com today.

Let MetalsTek be your trusted partner in advanced materials.