Introduction: Why Nickel Iron Alloys Matter

Nickel Iron (Ni–Fe) alloys occupy a unique and irreplaceable position in modern materials engineering. Unlike conventional structural metals that are selected primarily for strength or corrosion resistance, Nickel Iron alloys are chosen for functional performance—especially where magnetic behavior, dimensional stability, and thermal predictability are critical.

Nickel Iron Alloy Sheets and Bars are not commodity materials. They are engineered solutions used when even small deviations in magnetic response or thermal expansion can compromise system performance, reliability, or measurement accuracy. This is why Ni–Fe alloys are deeply embedded in industries such as electronics, aerospace, energy systems, scientific instrumentation, and high-end industrial manufacturing.

This article provides a deep, application-focused analysis of where Nickel Iron Alloy Sheets and Bars are used, why they are selected, and how their properties translate into real-world engineering value.

Understanding Nickel Iron Alloy Sheets and Bars

Before discussing applications, it is important to understand the functional role of product form.

- Nickel Iron Alloy Sheets are flat-rolled products optimized for forming, stamping, laminating, shielding, and surface-based functions.

- Nickel Iron Alloy Bars are solid forms designed for machining, structural support, magnetic cores, and load-bearing or dimensional-critical components.

Although they share the same base alloy system, sheets and bars often serve very different roles in engineering systems.

Electronics and Electrical Engineering Applications

Magnetic Shielding in Sensitive Electronics

One of the most widespread uses of Nickel Iron Alloy Sheets is magnetic shielding. In modern electronics, electromagnetic interference (EMI) can degrade signal integrity, increase noise, and cause system instability.

Nickel Iron alloys with high magnetic permeability are used to:

- Enclose sensitive electronic circuits

- Shield sensors from external magnetic fields

- Reduce interference in communication devices

- Protect precision measurement electronics

Sheets are preferred in these applications because they can be easily formed into enclosures, covers, or layered shielding assemblies. The uniform thickness and flatness of Nickel Iron Alloy Sheets directly influence shielding efficiency and repeatability.

Sensor and Signal Component Housings

Nickel Iron Alloy Bars are frequently machined into sensor housings, frames, and support structures for devices such as:

- Current sensors

- Magnetic field sensors

- Hall-effect devices

- Inductive measurement systems

In these applications, the material must not distort or unpredictably interact with the sensor’s magnetic field. Nickel Iron alloys offer controlled magnetic behavior, ensuring that the housing supports, rather than interferes with, sensor function.

Lead Frames and Precision Stamped Parts

In semiconductor and electronic packaging, Nickel Iron Alloy Sheets are used for:

- Lead frames

- Precision stamped conductive supports

- Thermal-mechanical interface components

The combination of good mechanical strength, controlled expansion, and process consistency allows Ni–Fe sheets to maintain alignment during thermal cycling in electronic assemblies.

Aerospace and Defense Applications

Dimensional Stability Under Temperature Variation

Aerospace systems experience extreme and rapidly changing temperatures. Materials that expand or contract unpredictably can cause misalignment, signal drift, or mechanical failure.

Nickel Iron Alloy Sheets and Bars are selected for aerospace components such as:

- Instrument frames

- Navigation system housings

- Sensor mounts

- Structural reference components

Their predictable thermal expansion behavior ensures that components maintain alignment from ground conditions to high-altitude or space environments.

Precision Instrumentation and Guidance Systems

In defense and aerospace guidance systems, accuracy is non-negotiable. Nickel Iron Alloy Bars are machined into:

- Gyroscope housings

- Inertial navigation components

- Precision spacers and alignment fixtures

The dimensional stability of these alloys reduces long-term drift and ensures consistent system calibration over extended service life.

Magnetic Control and Shielding in Avionics

Modern avionics systems integrate numerous electronic subsystems in confined spaces. Nickel Iron Alloy Sheets are used to:

Shield avionics modules

Control magnetic field distribution

Reduce cross-interference between components

These applications demand materials with repeatable magnetic properties across production batches—one of the key advantages of Nickel Iron alloys.

Energy and Power Systems

Transformer and Inductor Components

Nickel Iron alloys have long been used in magnetic components for power systems, particularly where efficiency and signal fidelity are prioritized over cost.

Applications include:

- Transformer cores

- Inductor laminations

- Magnetic flux guides

Nickel Iron Alloy Sheets are laminated to reduce eddy current losses, while Bars are used for solid magnetic structures where geometry control is critical.

Power Monitoring and Measurement Devices

Accurate power monitoring relies on stable magnetic environments. Nickel Iron Alloy Bars and Sheets are used in:

- Current transformers

- Power sensors

- Energy monitoring modules

The controlled magnetic permeability of Ni–Fe alloys enables precise signal detection without unwanted distortion.

Renewable Energy Equipment

In renewable energy systems such as wind and solar installations, Nickel Iron alloys support:

- Sensor systems for monitoring output

- Magnetic shielding for control electronics

- Structural components in precision measurement assemblies

Their reliability under long-term operation makes them suitable for infrastructure-scale deployment.

Scientific Instruments and Research Equipment

Precision Measurement Systems

Scientific instruments often operate at the limits of measurement sensitivity. Even minor material-induced distortions can compromise results.

Nickel Iron Alloy Sheets and Bars are used in:

- Metrology equipment

- Magnetic field measurement systems

- Calibration instruments

Their stable magnetic and thermal behavior supports consistent and repeatable measurements.

Vacuum and Cryogenic Systems

In vacuum and cryogenic research environments, materials must remain stable under extreme conditions.

Nickel Iron Alloy Bars are machined into:

- Vacuum system components

- Cryogenic support structures

- Precision mounts and fixtures

Nickel Iron Alloy Sheets are used for panels, shielding, and enclosures where cleanliness and dimensional integrity are essential.

Experimental Fixtures and Prototyping

Research laboratories value materials that behave predictably during experimentation. Nickel Iron alloys are frequently chosen for custom experimental fixtures, allowing researchers to isolate variables without worrying about material-induced anomalies.

Industrial Manufacturing and Automation

Precision Machined Components

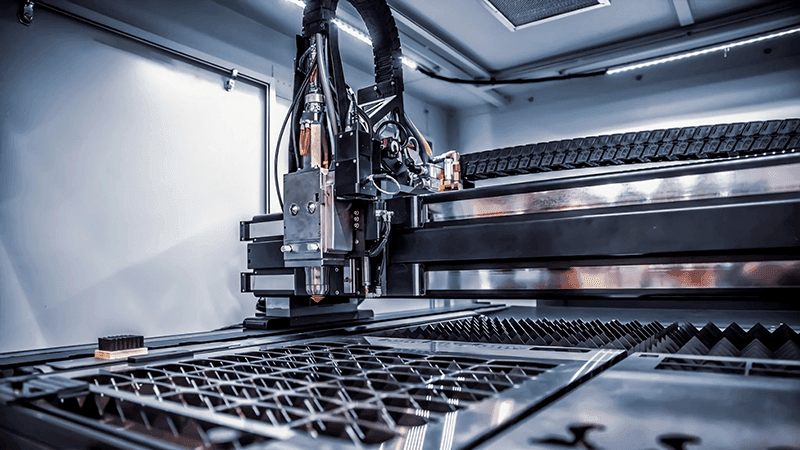

Nickel Iron Alloy Bars are widely used in CNC machining for parts that require:

- Tight dimensional tolerances

- Stable magnetic behavior

- Consistent mechanical properties

Typical components include:

- Machine frames for precision equipment

- Magnetic alignment parts

- Specialized connectors and supports

The predictable machinability of Nickel Iron alloys helps reduce scrap rates and rework.

Automation and Robotics Systems

In automation systems, sensors, actuators, and controllers often operate in close proximity. Nickel Iron Alloy Sheets are used to:

- Shield sensitive electronics

- Control magnetic field distribution

- Provide structural support without interference

Bars are used for load-bearing parts where stability and long-term reliability are critical.

Tooling and Specialized Industrial Equipment

Nickel Iron alloys are also found in specialized tooling where conventional steels fall short. Their combination of strength, stability, and magnetic control makes them suitable for niche industrial applications.

Role of Sheet vs. Bar in Application Design

| Product Form | Primary Function | Typical Use |

|---|---|---|

| Sheet | Forming, shielding, laminating | Electronics, shielding, panels |

| Bar | Machining, structural support | Housings, cores, fixtures |

Choosing between sheet and bar is not merely a dimensional decision—it directly affects performance, cost, and manufacturing efficiency.

Why Engineers Choose Nickel Iron Alloys

Nickel Iron Alloy Sheets and Bars are selected when applications demand:

- Controlled magnetic properties

- Predictable thermal expansion

- Long-term dimensional stability

- Compatibility with precision manufacturing

- Reliable performance over extended service life

These advantages explain why Nickel Iron alloys remain a preferred solution in high-value, performance-driven industries.

Typical Technical Parameters

| Parameter | Typical Range | Application Impact |

|---|---|---|

| Composition | Ni–Fe (custom ratios) | Defines magnetic & thermal behavior |

| Sheet Thickness | 0.1 – 6.0 mm | Controls shielding & forming |

| Bar Size | 5 – 150 mm | Determines machining options |

| Heat Treatment | Annealed / Customized | Stabilizes properties |

| Surface Finish | Rolled / Machined | Influences assembly |

Packaging and Handling

Nickel Iron Alloy Sheets and Bars are packaged with strict attention to cleanliness, surface protection, and traceability. Proper packaging prevents corrosion, deformation, and contamination, ensuring materials arrive ready for immediate use in precision applications.

Conclusion: A Strategic Engineering Material

Nickel Iron Alloy Sheet and Bar products are not selected by chance. They are chosen because they solve problems that conventional materials cannot—problems involving magnetic stability, thermal predictability, and dimensional control.

From electronics and aerospace to energy systems, scientific research, and advanced manufacturing, Nickel Iron alloys enable reliable, repeatable, and high-performance solutions. Their continued use across demanding industries highlights their enduring engineering value.

For applications requiring dependable Nickel Iron Alloy Sheets or Bars with customizable specifications, Metalstek provides materials engineered for precision, consistency, and long-term performance.

For technical details, application support, or quotations, please contact sales@metalstek.com.