Introduction

Vacuum furnaces and crystal growth systems represent some of the most demanding thermal environments in modern industry. They operate at temperatures reaching 2000 °C or higher, under high vacuum or controlled inert atmospheres, to enable processes such as sintering, annealing, brazing, and single-crystal production.

In these environments, ordinary metals cannot survive—only refractory materials like tungsten (W), molybdenum (Mo), and their advanced alloys (WCu, MoLa, TZM) maintain stability, conductivity, and mechanical integrity.

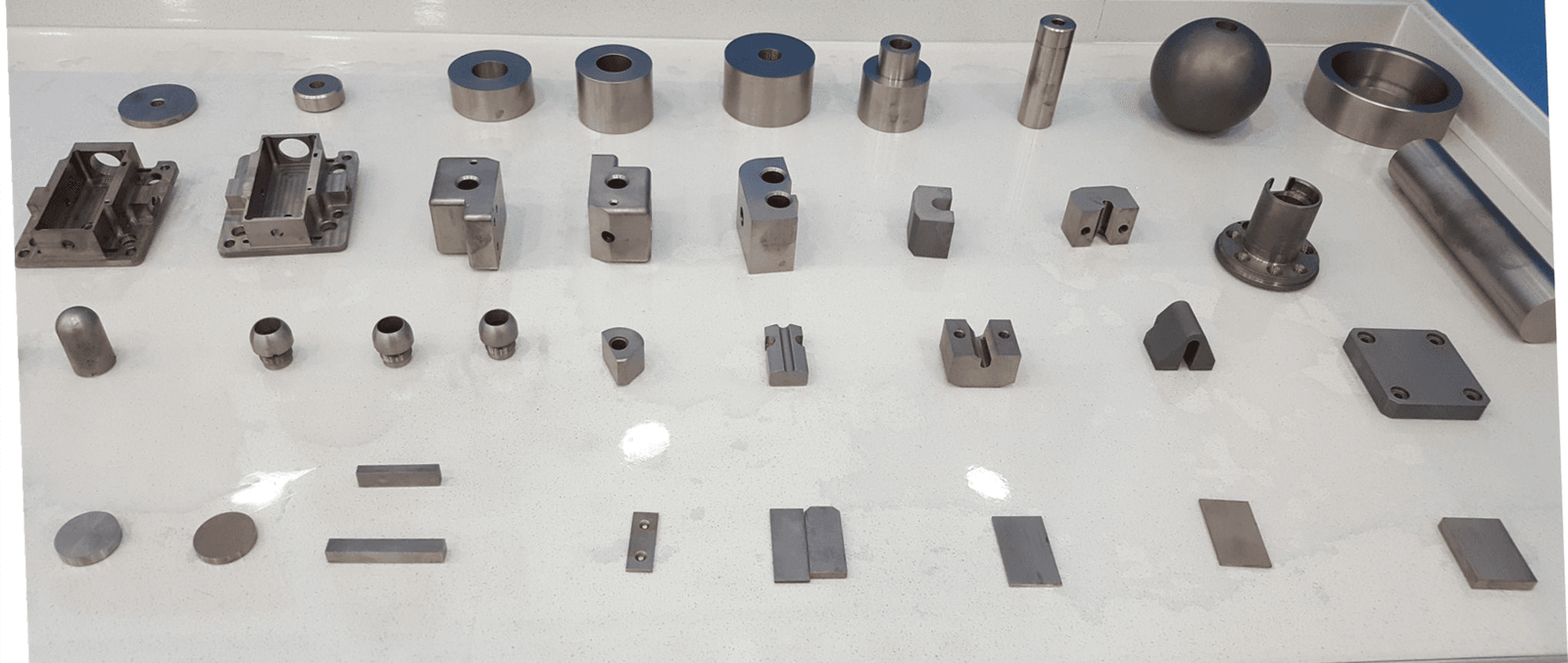

Metalstek Engineering specializes in manufacturing high-precision components from these refractory materials. Through decades of materials expertise and precision engineering, Metalstek delivers critical components for vacuum furnace manufacturers, semiconductor equipment builders, and crystal-growth system designers around the world.

1. The Role of Vacuum Furnaces and Crystal Growth Systems

Vacuum furnaces and crystal-growth systems are used where purity, control, and thermal performance are paramount.

1.1 Vacuum Furnaces

A vacuum furnace uses a sealed chamber to eliminate oxidation and contamination during high-temperature treatments. Typical applications include:

- Hard-metal sintering (e.g., tungsten carbide tools)

- Heat treatment of titanium and superalloys

- Vacuum brazing of precision parts

- Degassing and annealing of electronic components

1.2 Crystal Growth Systems

Crystal growth systems, such as Czochralski (CZ), Bridgman, or Float-Zone (FZ) furnaces, are employed to produce monocrystalline materials—silicon, sapphire, yttrium aluminum garnet (YAG), and others—for semiconductor wafers, lasers, and optics.

In both systems, temperature uniformity, thermal shock resistance, and vacuum compatibility define the quality and yield of the final product. Therefore, the performance of the internal components—heaters, shields, crucibles, electrodes, and supporting structures—is critical.

2. Challenges in High-Temperature, High-Vacuum Environments

Operating under vacuum changes the rules of heat transfer and material behavior.

| Challenge | Description | Consequence |

|---|---|---|

| Extreme Temperature (≥ 1800 °C) | Conventional metals melt or deform. | Requires refractory metals with > 3000 °C melting points. |

| Vacuum Conditions | No convection; only radiation and conduction for heat transfer. | Materials must maintain high emissivity and conductivity. |

| Chemical Purity | Outgassing or contamination can ruin crystal quality. | Use of low-vapor-pressure, high-purity metals essential. |

| Thermal Cycling | Rapid heating/cooling during operation. | Demands materials with good thermal shock resistance and ductility. |

| Mechanical Stress | Differential expansion in multi-material assemblies. | Alloys must retain mechanical integrity at temperature. |

Among all candidate materials, tungsten, molybdenum, and their composites remain unmatched for high-temperature stability and purity.

3. Key Materials for Vacuum Furnace and Crystal-Growth Components

3.1 Tungsten Copper Alloy (WCu)

WCu is a pseudo-alloy combining the high thermal and electrical conductivity of copper with the extreme melting point and strength of tungsten. It is produced by infiltrating porous tungsten skeletons with molten copper under vacuum.

Typical Composition: 70–90 wt% W + Cu balance.

Advantages:

- Excellent heat conduction for electrodes and heat sinks.

- High arc-erosion resistance.

- Dimensional stability under rapid thermal cycling.

- Good machinability compared with pure tungsten.

Applications:

- Vacuum furnace contacts, electrodes, and heat spreaders.

- Electrodes for electrical discharge machining (EDM).

- Crucible supports in CZ silicon pulling.

- Heat sinks in power semiconductor assemblies.

Performance Metrics:

- Thermal conductivity: 180–220 W/m·K (depending on Cu content)

- Melting range: composite > 3000 °C (W framework)

- Density: 14.5–17.5 g/cm³

Metalstek’s WCu components are manufactured via precision infiltration and vacuum sintering, ensuring uniform microstructure and bonding between phases.

3.2 Molybdenum Lanthanum Alloy (MoLa)

MoLa, or lanthanum-doped molybdenum, enhances ductility and creep resistance by introducing fine La₂O₃ dispersions into the molybdenum matrix.

Key Benefits:

- Improved recrystallization temperature (up to 1650 °C).

- Enhanced strength and toughness at elevated temperatures.

- Lower brittleness after multiple thermal cycles.

- Superior resistance to grain growth.

Applications:

- Heating elements and structural supports in crystal pullers.

- Reflector screens, heat shields, and thermal baffles in high-vacuum chambers.

- Components requiring both stiffness and formability.

Why MoLa Outperforms Pure Mo:

Pure molybdenum tends to embrittle after recrystallization around 1200 °C. La₂O₃ particles pin grain boundaries, preventing coarsening and maintaining ductility even after thousands of hours of operation.

Metalstek employs powder metallurgy and hot rolling processes to achieve homogeneous La₂O₃ distribution and consistent mechanical performance.

3.3 TZM Alloy (Titanium-Zirconium-Molybdenum)

TZM (Mo–0.5 Ti–0.08 Zr–0.02 C) is one of the most widely used molybdenum-based high-temperature alloys. The TiC and ZrC dispersions act as strong grain-boundary stabilizers.

Key Properties:

- Tensile strength > 700 MPa at 1000 °C.

- Good creep resistance up to 1400 °C.

- Low vapor pressure—ideal for ultra-high vacuum.

- High thermal conductivity (~ 125 W/m·K).

Applications:

- Hot zones in vacuum furnaces.

- Furnace nozzles, dies, and supports.

- Crucible liners and seed holders in crystal growth furnaces.

Typical Advantages vs. Pure Mo:

| Property | Mo | TZM |

|---|---|---|

| Recrystallization temp. | 1200 °C | 1500 °C |

| Yield strength (1000 °C) | 350 MPa | 700 MPa |

| Creep resistance | Moderate | Excellent |

| Ductility | Moderate | Higher after thermal cycles |

Metalstek fabricates TZM parts using isostatic pressing, hot rolling, and CNC machining under inert conditions to ensure microstructural stability.

4. Precision Component Types and Their Roles

| Component | Typical Material | Function |

|---|---|---|

| Heating Elements | MoLa, TZM, W | Convert electrical energy to uniform radiant heat. |

| Heat Shields | Mo, MoLa | Minimize heat loss and protect chamber walls. |

| Crucibles and Liners | W, Mo, WCu | Contain melt during crystal growth; resist chemical attack. |

| Electrodes / Feedthroughs | WCu | Conduct current under high vacuum. |

| Support Rods and Fixtures | TZM, MoLa | Maintain geometry during heating cycles. |

| Thermal Baffles and Reflectors | Mo, MoLa | Control temperature gradients and reflect heat. |

Each component must be precisely machined to micrometer tolerances, as uneven gaps or stress concentrations can cause local overheating or cracking during operation.

5. Performance and Service Life

The longevity of furnace and crystal-growth components depends on three interlinked factors: material purity, microstructure, and fabrication precision.

5.1 Material Purity

Even trace impurities (e.g., O, C, Si) can evaporate or react under vacuum, contaminating sensitive crystals. Metalstek’s materials achieve purities up to 99.95 %–99.99 % (3N5–4N), verified through ICP-MS analysis.

5.2 Microstructure and Density

Vacuum-sintered tungsten and molybdenum parts from Metalstek feature high densification (> 99.8 %) and fine grain size (< 50 µm). This minimizes vaporization and enhances mechanical consistency at elevated temperatures.

5.3 Dimensional and Surface Precision

Machining accuracy directly affects assembly alignment and heat distribution. Metalstek maintains dimensional tolerances within ± 0.01 mm and offers polished or textured finishes depending on emissivity requirements.

Typical Service Life:

- WCu electrodes: 3 – 5 years in intermittent operation.

- MoLa shields: up to 10 years in crystal-pulling systems.

- TZM fixtures: 2 – 3 times longer life than pure molybdenum counterparts.

6. Design and Manufacturing at Metalstek Engineering

6.1 Material Selection Consultation

Each customer application is analyzed for:

- Operating temperature range

- Atmosphere (vacuum, H₂, Ar, N₂)

- Mechanical load and geometry constraints

- Chemical compatibility with melt materials

Metalstek engineers recommend optimal alloys and design adjustments to balance performance, cost, and longevity.

6.2 Fabrication Process

- Powder Preparation: High-purity tungsten/molybdenum powder refined via hydrogen reduction.

- Compaction and Sintering: Isostatic pressing followed by vacuum sintering at 2000 – 2400 °C.

- Hot Working: Forging, rolling, or HIP to improve grain alignment.

- CNC Machining: Ultra-precision milling, turning, and EDM cutting.

- Inspection: Dimensional and metallographic verification per ISO 9001 standards.

- Surface Finishing: Polishing, sandblasting, or chemical cleaning to meet vacuum cleanliness standards.

6.3 Quality Assurance

All parts undergo:

- Density and hardness testing.

- Ultrasonic flaw detection.

- Outgassing and residual gas analysis (RGA).

- Mechanical property testing up to 1500 °C.

7. Emerging Trends in Furnace and Crystal-Growth Materials

- Hybrid Material Systems: Combining WCu with graphite or ceramics for improved thermal uniformity.

- Additive Manufacturing: Early trials of selective laser melting (SLM) with molybdenum powders for complex shapes.

- Coated Refractory Components: Surface nitridation or silicide coatings extend service life.

- Digital Thermal Simulation: FEM modeling of temperature gradients to optimize component geometry.

- Recycling and Circular Economy: Recovery of spent W and Mo materials through hydrogen reduction—Metalstek is investing in closed-loop recycling.

8. Case Example: MoLa Shields in Sapphire Crystal Growth

A sapphire growth equipment manufacturer required heat shields capable of maintaining ± 2 °C temperature uniformity at 1900 °C for over 3000 hours.

Metalstek supplied MoLa shields with precise curvature and double-layer reflective design. The results:

- Extended shield life by 40 %.

- Reduced impurity contamination to < 1 ppm.

- Improved crystal yield and optical clarity.

This project demonstrates how optimized materials and precision engineering directly translate to higher efficiency and reliability.

Conclusion

As industries pursue higher purity, tighter process control, and improved thermal efficiency, the demand for advanced refractory metal components continues to grow.

WCu, MoLa, and TZM alloys offer an ideal balance between strength, stability, and conductivity, making them indispensable in vacuum furnaces and crystal growth systems.

Through Metalstek Engineering’s expertise in material science, vacuum sintering, and precision machining, customers gain access to components that ensure:

- Consistent performance under extreme conditions,

- Longer service life and lower maintenance, and

- Higher process yields in advanced material production.

Metalstek remains committed to developing next-generation refractory metal solutions that empower high-temperature industries worldwide.

You May Also Want to Know

- What is the difference between MoLa and TZM?

MoLa offers higher ductility, while TZM provides superior strength at elevated temperatures. - Can WCu components be brazed or joined?

Yes, with proper metallization or diffusion bonding under vacuum. - What purity level is recommended for crystal growth applications?

Minimum 3N5 (99.95 %), ideally 4N (99.99 %). - How does Metalstek ensure flatness in large-area shields?

Through controlled hot rolling and precision CNC forming. - Are coatings useful for refractory metal parts?

MoSi₂ or ZrO₂ coatings can significantly reduce oxidation during maintenance. - How often should furnace components be replaced?

Depending on cycle frequency, MoLa/TZM parts typically last 3–5 years. - Can these materials be customized for specific thermal profiles?

Yes, geometry and alloy composition are tailored per thermal model simulation. - Is recycling possible for spent tungsten or molybdenum parts?

Metalstek offers recovery programs to reclaim and refine spent components. - What machining tolerances are achievable?

Up to ± 0.01 mm for precision fixtures and electrodes. - Where are Metalstek components used globally?

In semiconductor fabs, sapphire growth plants, aerospace R&D labs, and metallurgical industries.