Introduction

Silver Copper Alloy Powder (AgCu powder) is a functional metallic material that combines the exceptional electrical and thermal conductivity of silver with the mechanical strength, cost efficiency, and alloy-strengthening effect of copper. In powder form, AgCu alloys exhibit a unique balance of conductivity, wettability, sinterability, and structural stability, making them highly suitable for advanced manufacturing routes such as powder metallurgy, thick-film processing, additive manufacturing, brazing, and conductive paste formulation.

As electronic devices continue to shrink while power density, reliability, and operating temperature increase, pure silver or pure copper powders often struggle to meet all performance requirements simultaneously. AgCu alloy powder fills this gap by offering tunable properties through controlled silver-to-copper ratios, particle size distributions, and powder morphologies. This flexibility has driven its adoption across electronics, energy, aerospace, automotive, and high-end industrial applications.

The following sections provide an in-depth analysis of the major application scenarios of Silver Copper Alloy Powder, focusing on why AgCu powder is selected, how it performs in real-world conditions, and what functional advantages it brings to each industry.

1. Electronic Packaging and Interconnection Materials

1.1 Conductive Pastes and Thick-Film Circuits

One of the most established application areas for AgCu alloy powder is conductive pastes used in thick-film circuits and hybrid electronic modules. Compared with pure silver powder, AgCu powder significantly improves resistance to silver migration, a phenomenon that can cause short circuits under high humidity and electric fields.

Key advantages in conductive pastes include:

Stable electrical conductivity over long service life

Improved adhesion to ceramic and glass substrates

Reduced material cost compared with pure silver systems

Enhanced resistance to electrochemical corrosion

AgCu powders are commonly used in:

Thick-film electrodes on alumina or aluminum nitride substrates

Conductive traces for power electronics modules

Multilayer ceramic circuit interconnections

The copper component also promotes better mechanical robustness of printed conductors, reducing cracking during thermal cycling.

1.2 Die Attach and Power Semiconductor Packaging

In power semiconductor packaging, AgCu alloy powder is widely used in sintered die-attach materials. Compared with traditional solder systems, sintered AgCu joints offer superior thermal conductivity, higher melting points, and excellent fatigue resistance.

Typical application scenarios include:

- IGBT and MOSFET die attach layers

- Wide bandgap semiconductor devices (SiC, GaN)

- High-temperature and high-power electronic modules

AgCu powder enables:

- Low-temperature sintering with high-temperature service stability

- High thermal conductivity for efficient heat dissipation

- Strong metallurgical bonding to copper, silver, and nickel surfaces

These properties are especially valuable in electric vehicles, renewable energy inverters, and industrial motor drives.

2. Brazing and Joining Technologies

2.1 Silver-Based Brazing Alloys

AgCu alloy powder is a core raw material for silver-based brazing alloys used in joining metals that require high joint strength and excellent thermal or electrical performance. Powder-based brazing materials allow precise composition control and uniform melting behavior.

Common brazing applications include:

- Copper-to-copper and copper-to-steel joints

- Stainless steel heat exchangers

- Electrical contacts and conductive joints

Compared with pure silver brazes, AgCu alloys offer:

- Lower silver content with comparable joint performance

- Improved wetting on copper and copper alloys

- Enhanced mechanical strength and creep resistance

Powder forms are particularly suitable for automated brazing processes, paste formulations, and pre-placed brazing rings.

2.2 Advanced Joining for Aerospace and Vacuum Systems

In aerospace and vacuum equipment, joining materials must withstand extreme thermal cycling and maintain low outgassing characteristics. AgCu alloy powder meets these requirements due to its clean microstructure and stable phase behavior.

Typical uses include:

- Vacuum feedthrough joints

- Sensor housings and hermetic seals

- High-reliability aerospace components

The powder metallurgy route enables dense, uniform brazed joints with minimal porosity, improving both mechanical integrity and vacuum performance.

3. Electrical Contacts and Switching Components

3.1 Low-Voltage and Medium-Voltage Electrical Contacts

AgCu alloy powder is widely used in the production of electrical contact materials through powder metallurgy. Compared with pure silver contacts, AgCu contacts exhibit better wear resistance, reduced material transfer, and longer service life.

Applications include:

- Relays and contactors

- Circuit breakers

- Switchgear and control systems

The copper phase enhances hardness and arc erosion resistance, while silver maintains excellent electrical conductivity. By adjusting Ag/Cu ratios, manufacturers can tailor contact performance for specific current levels and switching frequencies.

3.2 Sliding Contacts and Conductive Brushes

In sliding electrical contacts, such as conductive brushes or slip rings, AgCu alloy powder offers a balanced combination of conductivity and mechanical durability. The alloy structure reduces excessive wear while maintaining stable contact resistance.

These materials are used in:

- Precision motors and generators

- Aerospace actuators

- High-reliability instrumentation systems

4. Additive Manufacturing and Powder Metallurgy Components

4.1 Powder Metallurgy Structural Parts

Silver Copper Alloy Powder is increasingly used in powder metallurgy for producing near-net-shape conductive and structural components. Sintered AgCu parts combine good mechanical strength with functional conductivity.

Representative components include:

- Conductive structural inserts

- Heat-spreading components

- Specialized connectors and terminals

The powder form allows:

- Uniform alloy composition

- Controlled porosity or full densification

- Compatibility with conventional sintering or hot pressing processes

4.2 Additive Manufacturing and Functional Printing

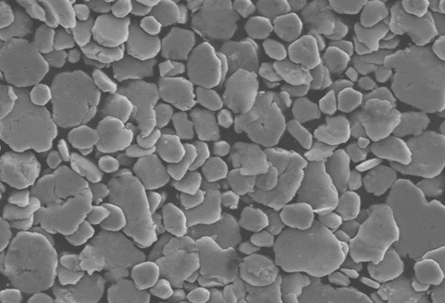

With the rise of metal additive manufacturing and functional printing technologies, AgCu powder is gaining attention for its processability and performance balance. Fine, spherical AgCu powders are suitable for:

- Binder jetting

- Material extrusion-based metal printing

- Specialized laser-assisted deposition processes

Potential applications include:

- Customized conductive components

- Integrated thermal-electrical structures

- Rapid prototyping of electronic hardware

5. Thermal Management and Heat Dissipation Applications

Silver is known for its superior thermal conductivity, while copper provides mechanical support and cost optimization. AgCu alloy powder leverages both advantages in thermal management materials.

Typical applications:

- Thermal interface materials (TIMs)

- Heat spreaders and thermal pads

- High-power LED and laser packaging

AgCu powder-based systems offer:

- High thermal conductivity

- Stable performance over wide temperature ranges

- Compatibility with metallurgical bonding processes

These characteristics are critical in compact, high-power electronic assemblies.

6. Energy and Renewable Technologies

6.1 Photovoltaic and Energy Storage Systems

In photovoltaic modules and energy storage devices, AgCu alloy powder is used in conductive pastes, interconnects, and joining layers. Compared with pure silver systems, AgCu formulations reduce silver consumption while maintaining performance.

Applications include:

- Busbars and conductive tracks

- Battery tab connections

- Power distribution components

6.2 Hydrogen and Fuel Cell Systems

Fuel cells and hydrogen energy systems require materials with excellent electrical conductivity, corrosion resistance, and thermal stability. AgCu alloy powder is explored for:

- Conductive coatings

- Electrical interconnects

- Specialized sealing and joining solutions

7. Research, Development, and Specialized Industrial Uses

Beyond mass production, AgCu alloy powder plays an important role in R&D environments where material performance optimization is critical.

Common research uses include:

- Development of novel conductive inks

- High-temperature joining experiments

- Functional composite material studies

The ability to customize particle size, composition, and morphology makes AgCu powder a flexible platform material for advanced material research.

Conclusion

Silver Copper Alloy Powder (AgCu) occupies a vital position in modern materials engineering due to its balanced combination of electrical conductivity, thermal performance, mechanical strength, and economic efficiency. Across electronic packaging, brazing, electrical contacts, powder metallurgy, additive manufacturing, thermal management, and energy systems, AgCu powder provides a versatile and reliable solution where neither pure silver nor pure copper alone can fully meet application demands.

Its adaptability through composition tuning and powder engineering ensures continued relevance as industries move toward higher power density, miniaturization, and improved reliability. As manufacturing technologies evolve, the application scope of AgCu alloy powder is expected to expand further, reinforcing its role as a cornerstone material in advanced industrial and electronic systems.

For detailed specifications, composition options, and application-specific recommendations, please contact us at sales@metalstek.com